Technology for removing bismuth from copper electrolyte with low cost

A copper electrolyte, low-cost technology, applied in the direction of photography technology, electrolysis process, electrolysis components, etc., can solve the problems of high cost, high energy consumption, etc., achieve the effect of extensive material collection, less additional equipment, and low processing cost

Active Publication Date: 2012-05-02

DONGYING FANGYUAN NONFERROUS METALS

View PDF9 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a method for the copper smelting industry to produce high-purity cathode copper by using high-antimony bismuth ore copper anode plate to remove bismuth (and antimony) process, so that the purified copper electrolyte contains less than 0.2g / l of bismuth and less than 0.3g / l of antimony, which solves the hidden danger of bismuth in terms of electrolyte composition and solves the problem of existing copper electrolyte removal of bismuth elements Existing problems of high energy consumption and high cost provide help for comprehensively improving the quality of electrical copper

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

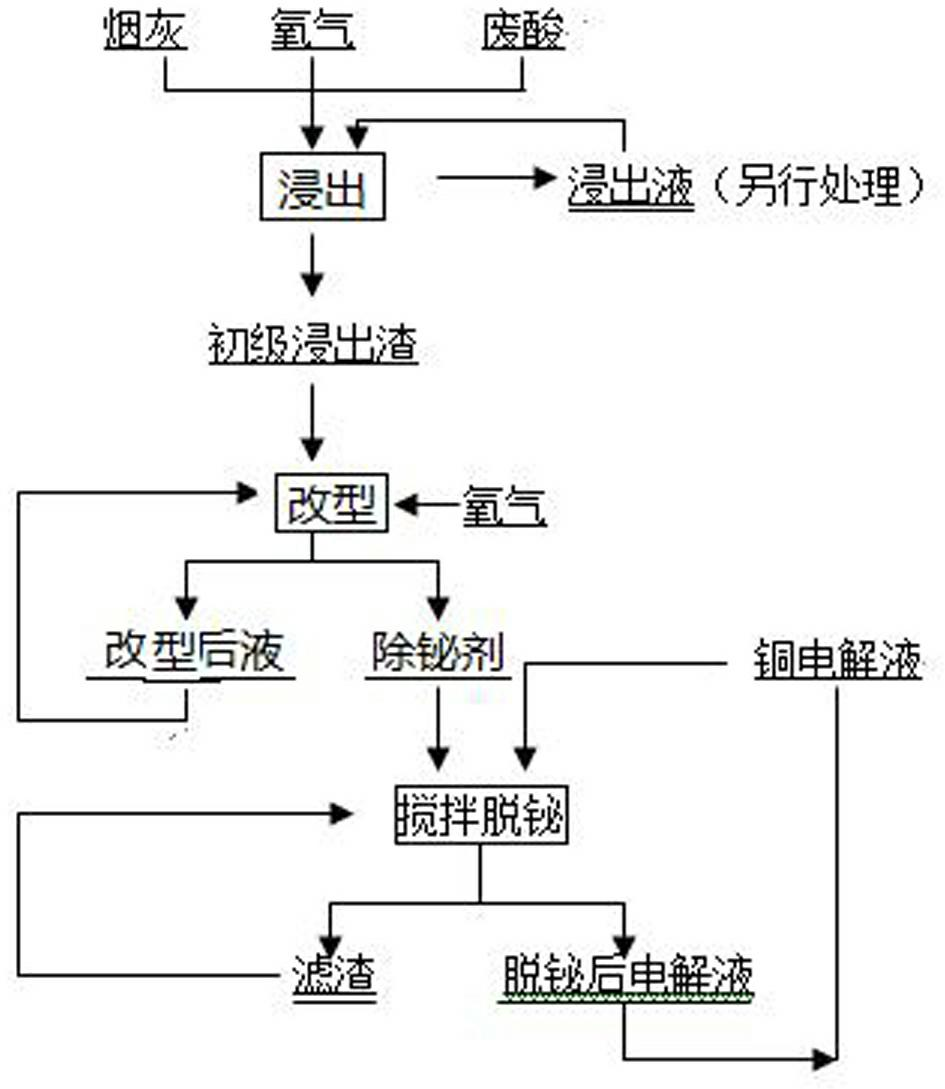

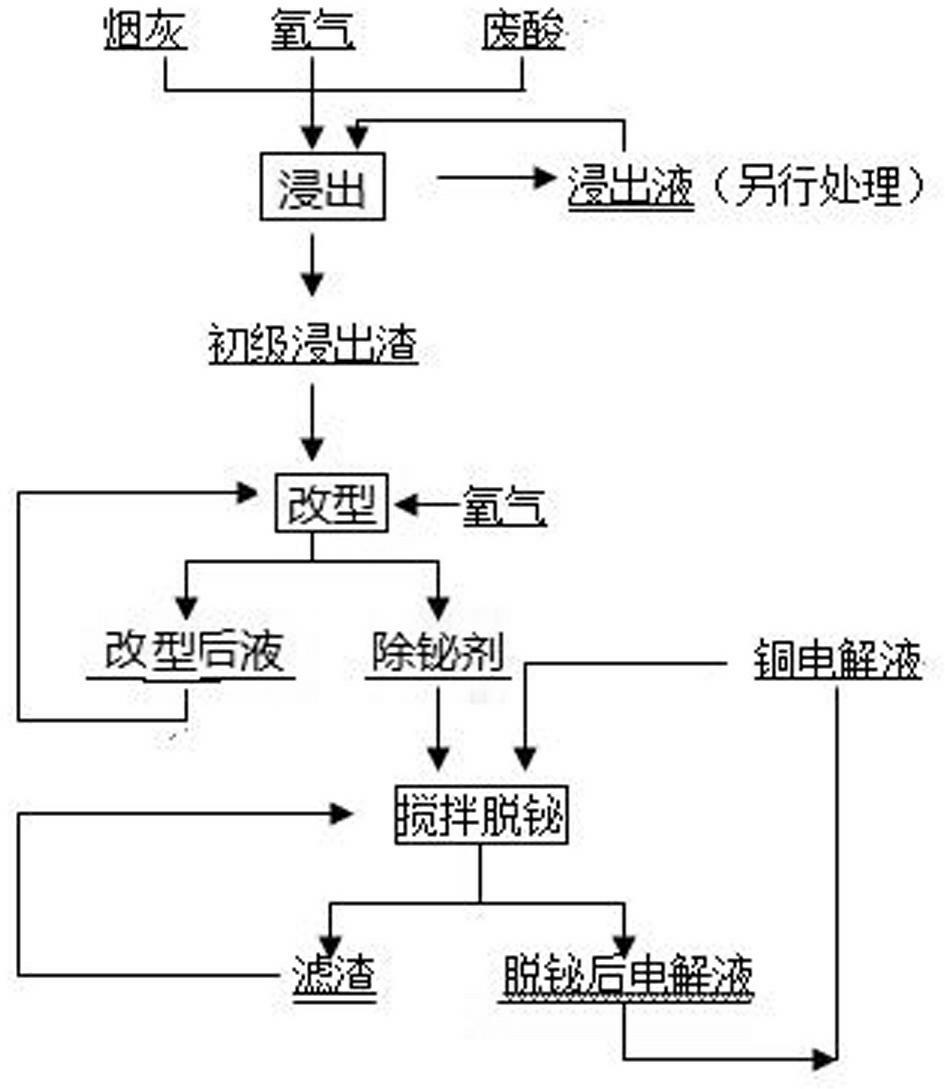

The invention discloses a technology for removing bismuth from copper electrolyte with low cost. The technology comprises the following steps of: leaching and filtering soot or slag to obtain primary leached residue, modifying the primary leached residue to obtain a modified bismuth removing agent, adding the modified bismuth removing agent into a reaction container, fully mixing and stirring the modified bismuth removing agent and the electrolyte, adsorbing and co-precipitating Bi, Sb and the like in the electrolyte through the bismuth removing agent by using the principle of similar adsorption of insoluble substances, and returning the filtered Bi-removed electrolyte to a production system, wherein the Bi removing effect of the bismuth removing agent declines after multiple times of cycle, the bismuth removing agent can be reused after resolving and pulverizing, and valuable metals in the bismuth removing agent can be recovered by treatment. 'Three wastes' are not produced in the whole process, normal production of a master system is not interfered, noble raw materials, high energy consumption and manpower resource expenses for the conventional bismuth (and antimony) removal are reduced, and harm of bismuth, antimony and arsenic of high-quality cathode copper produced by using a mineral copper anode plate is eliminated; and the technology is expected to become a new technical turning point of copper electrolytic refining, so that the copper electrolytic refining way is flatter.

Description

Technical field The invention belongs to the field of non-ferrous metallurgy, and relates to a process for removing bismuth from a copper electrolytic solution in the process of producing high-purity cathode copper through electrolytic refining of a copper anode plate produced by copper concentrate. Background technique In the process of copper smelting and purification, the pyro-refining process of blister copper cannot effectively remove Sb and Bi elements, which are mixed in the intercrystalline interface of copper in the form of complex oxides, intermetallic compounds or solid solutions, which is likely to cause the final copper anode plate The Sb and Bi impurity content in the medium exceeds the standard for copper electrolytic refining technology. In the copper electrolytic refining process, the hazards of Sb and Bi mainly depend on the concentrations of As, Sb and Bi in the electrolyte, while the concentrations of As, Sb and Bi in the electrolyte depend on the impurit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25C1/12C25C7/06

CPCY02P10/20

Inventor 吴志刚曾维王智边瑞民杨亮杜武钊

Owner DONGYING FANGYUAN NONFERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com