Agriculture and forestry plant waste high-efficient burning generating system

A plant waste, incineration technology for power generation, applied in the field of high-efficiency incineration of agricultural and forestry plant waste to generate power, can solve the problems of waste of resources, pollution of the environment, difficult to store, etc., achieve small investment and land occupation, low operating cost, and short processing cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

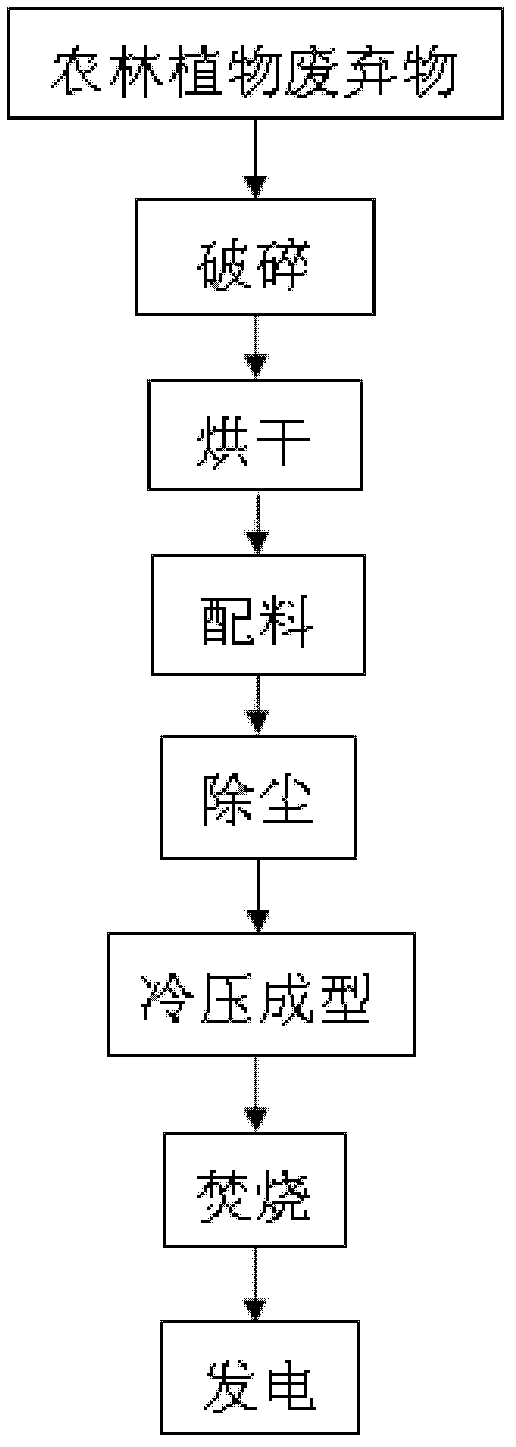

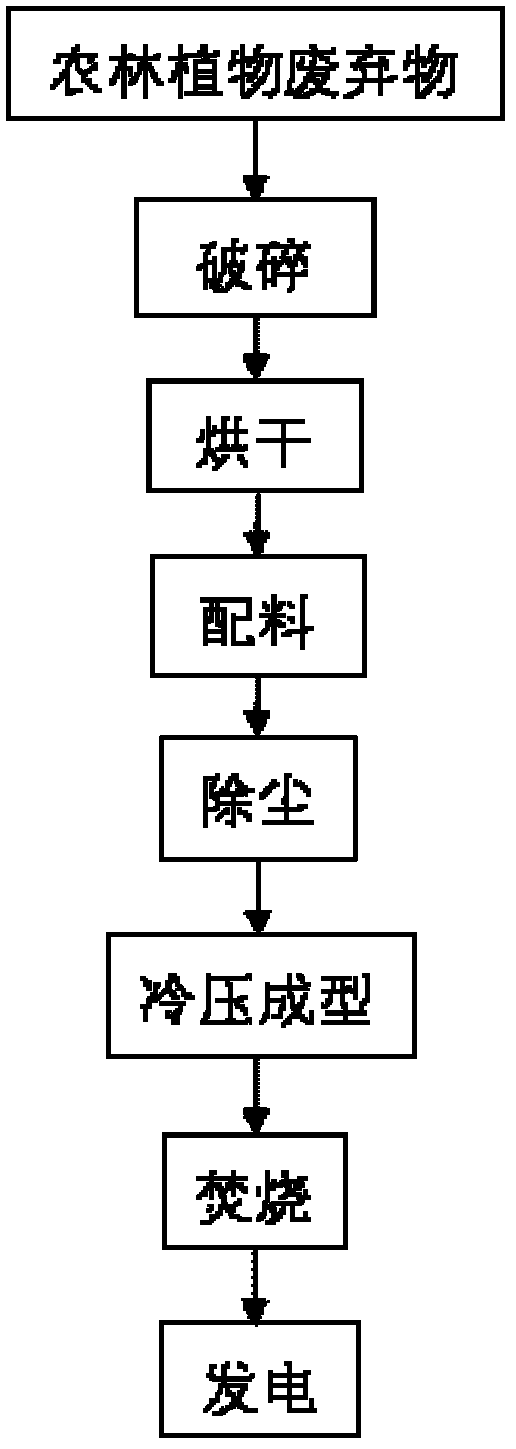

[0010] A high-efficiency incineration power generation system for agricultural and forestry plant wastes, comprising the following steps: (1) crushing: crushing collected plant wastes in agriculture and forestry (such as: straw, branches and weeds, fallen leaves, fruit shells, etc.); 2) Drying: dry by reciprocating dryer; (3) ingredients: add a certain amount of combustion aid and anti-slagging agent to the crushed agricultural and forestry plant waste; (4) dust removal: use bag filter , to remove impurities in the material; (5) cold press forming: through the biomass fuel block forming machine, the material is extruded and formed, and extruded into various shapes of biomass fuel blocks through different discharge dies, and The cold pressing process consumes less energy. Biomass fuel block shapes include cylindrical and multi-faceted block shapes, which are easy to burn and easy to transport and store. (6) Incineration: Combustion through a new type of biomass boiler, the bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com