Method for measuring formaldehyde and acetaldehyde content in paper for cigarette at the same time

A formaldehyde and acetaldehyde technology, applied in the field of physical and chemical inspection of cigarette packaging materials, to achieve good linear correlation, good repeatability, and good peak shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

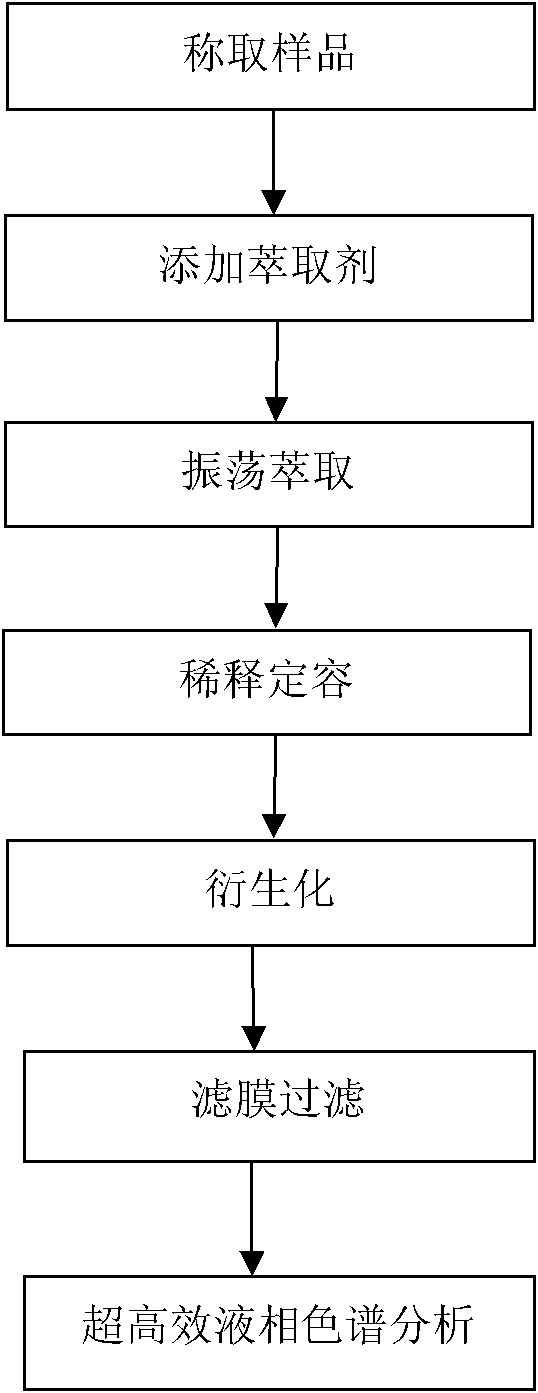

[0032] Determination of the content of formaldehyde and acetaldehyde in the hard box packing paper (determination method flow process is as follows figure 1 shown);

[0033] 1. Preparation of standard working solution

[0034] (1) Preparation of mixed standard stock solution: Weigh 200 mg of formaldehyde-2,4-dinitrophenylhydrazone and 200 mg of acetaldehyde-2,4-dinitrophenylhydrazone respectively, put them in the same 100mL volumetric flask, and use Acetonitrile was dissolved and the volume was adjusted to the mark to obtain a mixed standard stock solution;

[0035] (2) Preparation of standard working solution: pipette 0.5mL of mixed standard stock solution into a 50mL volumetric flask, dissolve and mix with acetonitrile and set the volume to the mark to obtain the first-level standard working solution; take the first-level standard working solution Add 20.00mL into a 50mL volumetric flask, dissolve and mix with acetonitrile and adjust the volume to the mark to obtain the se...

Embodiment 2

[0059] Determination of the content of formaldehyde and acetaldehyde in the soft box wrapping paper (determination method flow process is as follows figure 1 shown);

[0060] 1. Preparation of standard working solution: Weigh 200 mg of formaldehyde-2,4-dinitrophenylhydrazone and 100 mg of acetaldehyde-2,4-dinitrophenylhydrazone, and the rest are the same as in Example 1.

[0061] 2. Preparation of sample solution and blank solution

[0062] (1) Preparation of sample solution: Take a piece of soft box wrapping paper, accurately cut out the main packaging surface, and a sample with an area of 15.5cm × 10.0cm, then weigh it (accurate to 0.1mg), and put it in a 100mL triangular flask with a stopper Cut it into pieces with sterile scissors, add 50.0mL of 4% acetic acid solution, place it on a shaker, shake and extract for 30min. After standing still, accurately pipette 1.0mL of clear liquid into a 10mL volumetric flask, add 4mL of derivatization reagent, dilute to volume with a...

Embodiment 3

[0069] Determination of the content of formaldehyde and acetaldehyde in the wrapping paper (determination method flow process is as follows figure 1 shown);

[0070] 1. Preparation of standard working solution: weigh 200 mg of formaldehyde-2,4-dinitrophenylhydrazone and acetaldehyde-2,4-dinitrophenylhydrazone 200 mg, all the other are the same as in Example 1.

[0071] 2. Preparation of sample solution and blank solution

[0072] (1) Preparation of sample solution: Take a piece of wrapping paper, accurately cut out a sample with an area of 22.0cm×5.5cm in the central area of the front of the package, weigh it (accurate to 0.1mg), and place it in a 100mL conical flask with a stopper Cut it into pieces with sterile scissors, add 50.0mL of 4% acetic acid solution, place it on a shaker, shake and extract for 30min. After standing still, accurately pipette 1.0mL of clear liquid into a 10mL volumetric flask, add 4mL of derivatization reagent, dilute to volume with acetonitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com