Ion liquid reinforced film for vanadium ion redox flow battery and preparation method thereof

An all-vanadium redox flow battery, ionic liquid technology, applied in fuel cells, battery pack components, fuel cell components, etc. Stable performance, improved energy efficiency and good electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

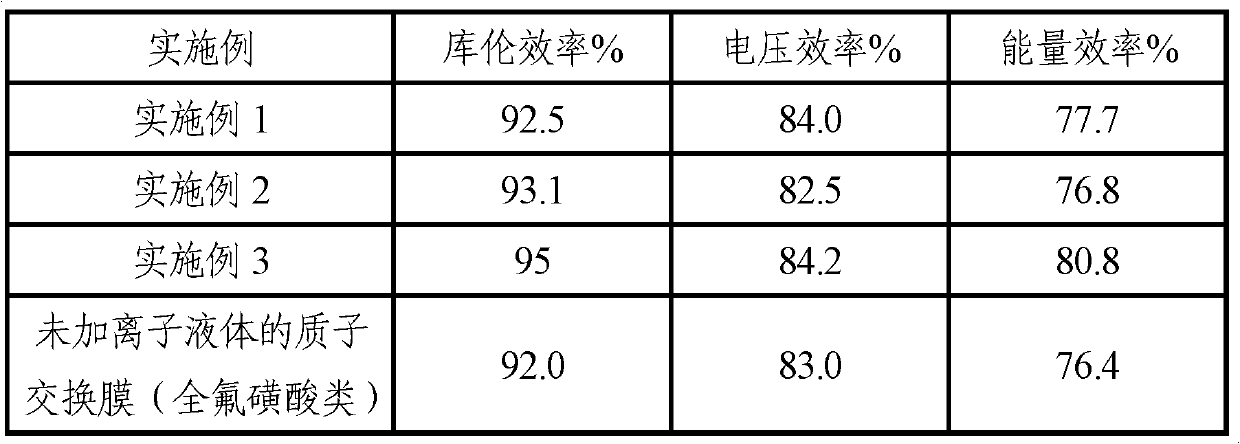

Embodiment 1

[0025] In this embodiment, the preparation method of the composite proton exchange membrane for the enhanced vanadium battery is as follows:

[0026] (1) Weigh a certain amount of perfluorosulfonic acid resin and dissolve it in nitrogen and nitrogen dimethylformamide (N,N-dimethylformamide) by stirring, and configure it into a matrix with a weight concentration of 40g / L Film-forming solution, then get 0.35g 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid and join in 80ml film-forming liquid (the weight percent of ionic liquid is 10%), by stirring 1 hour, then ultrasonic 30 Minutes to disperse the ionic liquid evenly.

[0027] (2) The dispersed solution was poured onto the pre-leveled flat glass, and after drying at 140°C for 2 hours, the enhanced proton exchange membrane was prepared and assembled into a battery for battery performance testing. In this embodiment, the thickness of the enhanced proton exchange membrane is 90 microns. The composition of the exchan...

Embodiment 2

[0030] The difference from Example 1 is that in this example, the preparation method of the proton exchange membrane for the ionic liquid enhanced vanadium battery is as follows:

[0031] (1) Weigh a certain amount of perfluorosulfonic acid resin and dissolve it in dimethyl sulfoxide by stirring, configure it as a matrix film-forming solution with a weight concentration of 40g / L, and then take 0.105g of 1-butyl-3 - Methylimidazolium hexafluorophosphate ionic liquid was added to 80ml of film-forming liquid (the weight percentage of ionic liquid was 3%), and the ionic liquid was uniformly dispersed by stirring for 30 minutes and then ultrasonication for 10 minutes.

[0032] (2) The dispersed solution was poured onto the pre-leveled flat glass, and after drying at 140°C for 3 hours, the enhanced proton exchange membrane was prepared and assembled into a battery for battery performance testing. In this embodiment, the thickness of the enhanced proton exchange membrane is 80 micron...

Embodiment 3

[0036] The difference from Example 1 is that in this example, the preparation method of the ion-exchange membrane for the enhanced vanadium battery is as follows:

[0037] (1) Weigh a certain amount of sulfonated polyether ether ketone and dissolve it in dimethyl sulfoxide by stirring, and configure it into a matrix film-forming solution with a weight concentration of 60g / L, and then take 0.96g of 1-butyl- The ionic liquid of 3-methylimidazolium hexafluorophosphate was added to 80ml of the film-forming liquid (the weight percentage of the ionic liquid was 20%), and the ionic liquid was uniformly dispersed by stirring for 2 hours and then ultrasonicating for 20 minutes.

[0038](2) The dispersed solution was poured onto the pre-leveled flat glass, and after drying at 140°C for 3 hours, the enhanced proton exchange membrane was prepared and assembled into a battery for battery performance testing. In this embodiment, the thickness of the enhanced proton exchange membrane is 120 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com