Graphene/boron nitride aerogel and preparation method thereof

An aerogel, boron nitride technology, applied in aerogel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problem of no aerogel patent, improve the explosion problem and achieve excellent thermal insulation performance , Improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Specifically, the preparation method of a graphene / boron nitride aerogel provided by the present invention comprises the following steps:

[0051] Step 1) Preparation of melamine diborate solution:

[0052] Melamine and boric acid are dissolved in a co-solvent to obtain a melamine diborate solution.

[0053] Step 2) freeze-drying the melamine diborate solution to obtain a melamine diborate aerogel.

[0054] Step 3) The melamine diborate aerogel is pyrolyzed in a high temperature atmosphere to obtain boron nitride aerogel.

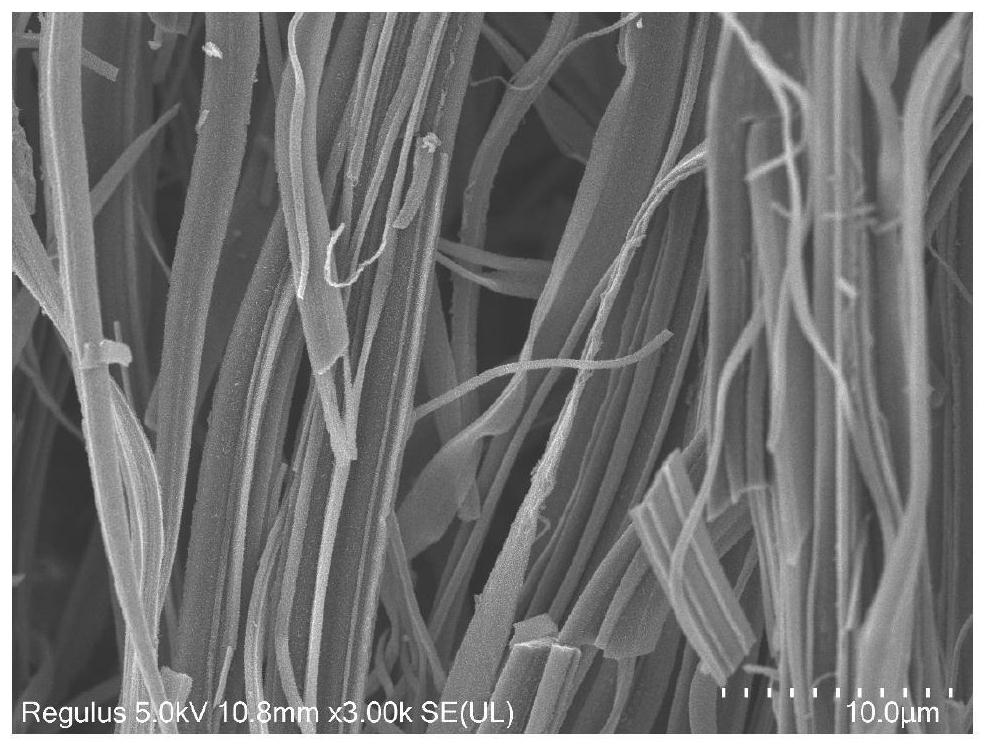

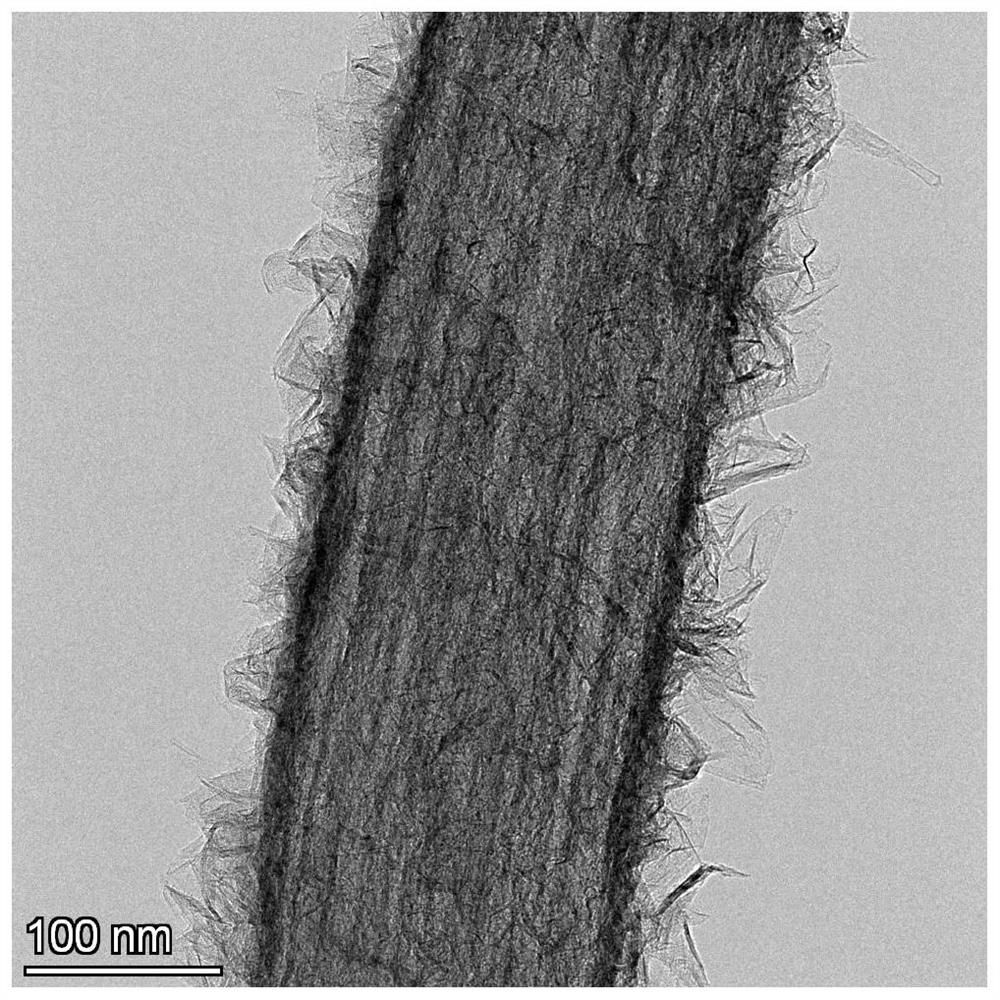

[0055] Step 4) adopting a chemical vapor deposition process in the boron nitride aerogel to achieve uniform grafting of graphene on the boron nitride substrate from the inside to the outside to obtain the graphene / boron nitride aerogel.

[0056] specifically:

[0057] In step 1), the molar ratio of melamine and boric acid is 1:5 to 5:1.

[0058] The mixed volume ratio of water to methanol, ethanol, isopropanol, n-butanol or tert-butanol in the co-s...

Embodiment 1

[0067] Weigh 0.4838g of melamine and 0.4762g of boric acid, and sequentially add them into 48mL of tert-butanol / distilled water co-solvent, wherein the ratio of tert-butanol to distilled water is 7:5, and the concentration of the mixed solution is 20mg / mL. The melamine diboric acid solution is obtained, which is transferred to a vacuum freeze dryer for processing for 24 hours, and the melamine diboric acid aerogel can be obtained.

[0068] The melamine diboric acid aerogel is transferred to a tube furnace, and the temperature is raised to 1100 °C in an ammonia / nitrogen environment for high temperature heat treatment for 3 hours to obtain boron nitride aerogel.

[0069] The obtained boron nitride aerogel is placed in a chemical vapor deposition furnace, and a chemical vapor deposition pump with an adjustable rate is used to control the residence time of the carbon source gas inside the boron nitride aerogel, and the sample is placed in the furnace cavity. Immediately after the ...

Embodiment 2

[0072] 0.2419g of melamine and 0.2381g of boric acid were weighed and added to 48mL of tert-butanol / distilled water co-solvent in turn, wherein the ratio of tert-butanol to distilled water was 7:5, and the concentration of the mixed solution was 10mg / mL. The melamine diboric acid solution is obtained, which is transferred to a vacuum freeze dryer for processing for 24 hours, and the melamine diboric acid aerogel can be obtained.

[0073] The melamine diboric acid aerogel is transferred to a tube furnace, and the temperature is raised to 1100 °C in an ammonia / nitrogen environment for high temperature heat treatment for 3 hours to obtain boron nitride aerogel.

[0074] The obtained boron nitride aerogel is placed in a chemical vapor deposition furnace, and a chemical vapor deposition pump with an adjustable rate is used to control the residence time of the carbon source gas inside the boron nitride aerogel, and the sample is placed in the furnace cavity. Immediately after the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com