Catalyst for preparing NaALH4 hydrogen storage system and preparation method of hydrogen storage system

A technology of sodium aluminum tetrahydrogen and a catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve problems such as large molecular weight, high temperature and high pressure, and lack of hydrogen storage capacity, and achieves a simple preparation method , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mixing of reactants

[0029] At room temperature and under the protection of argon, after weighing equimolar amounts of NaH and Al powders and placing them in a ball mill jar, add 8 mol% catalyst TiB to the above mixture 2 , mixed evenly to obtain a silver-gray mixture.

[0030] (2) Mechanical ball milling

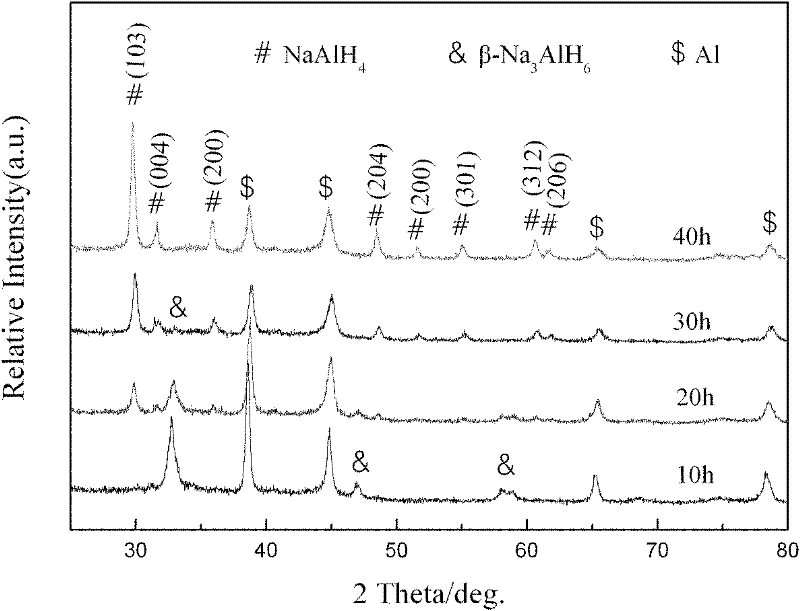

[0031] Under an argon atmosphere, stainless steel balls with a diameter of 10 mm were added according to the ball-to-material mass ratio of 40:1. The ball mill jar is sealed well, vacuumized, and then high-purity hydrogen gas with a pressure of 1 MPa is introduced. Adjust the rotational speed of the ball mill to 450rpm, place the ball mill tank on the ball mill for 40 hours, open the tank every 5 hours, and measure XRD every 10 hours. After 40 hours of ball milling, NaAlH with good hydrogen storage performance was obtained 4 , see attached figure 1 .

Embodiment 2

[0033] (1) Mixing of reactants

[0034] At room temperature and under the protection of argon, after weighing equimolar amounts of NaH and Al powders and placing them in a ball mill jar, add 8 mol% TiB to the above mixture 2 , mix evenly to obtain a mixture of silver ash.

[0035] (2) Mechanical ball milling

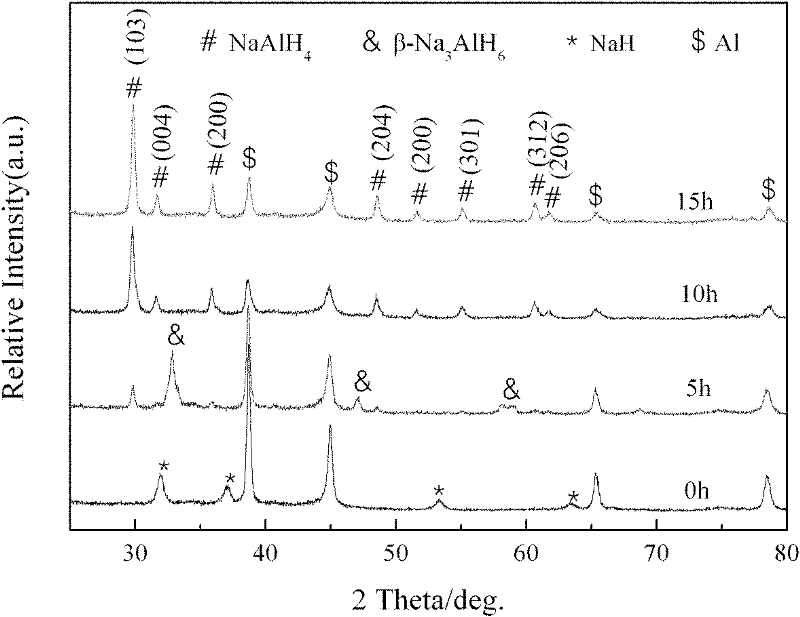

[0036] Under an argon atmosphere, stainless steel balls with a diameter of 10 mm were added according to the ball-to-material mass ratio of 40:1. Seal the ball mill tank well, vacuumize it, and then feed high-purity hydrogen gas with a pressure of 2MPa. Adjust the rotational speed of the ball mill to 450rpm, place the ball mill tank on the ball mill for milling for 15 hours, open the tank every 5 hours, and measure XRD every 5 hours. After 15 hours of ball milling, NaAlH with good hydrogen storage performance was obtained 4 , see attached figure 2 .

Embodiment 3

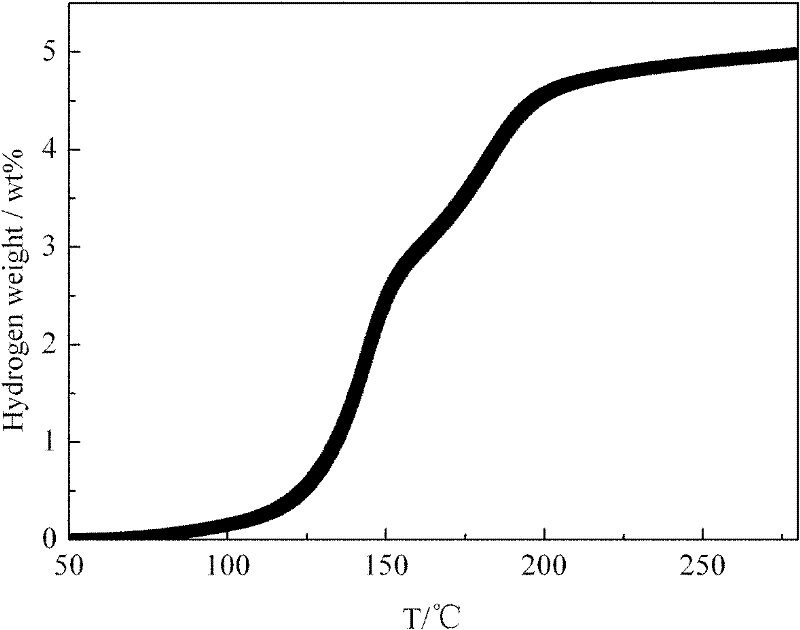

[0038] With the NaAlH that embodiment 1 obtains 4 Take TPD hydrogen desorption test as an example, the heating rate is 2°C / min. From attached image 3 It can be seen that NaAlH 4 The dehydrogenation temperature is obviously lowered, and the dehydrogenation capacity can reach 5.0wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com