High-dispersion anti-scaling agent of dry dust-removal blast furnace gas residual pressure turbine power generating system

A blast furnace gas and dry dust removal technology, applied in the field of scale inhibitor, can solve the problems of increased spindle vibration value, short system maintenance period, reduced TRT power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

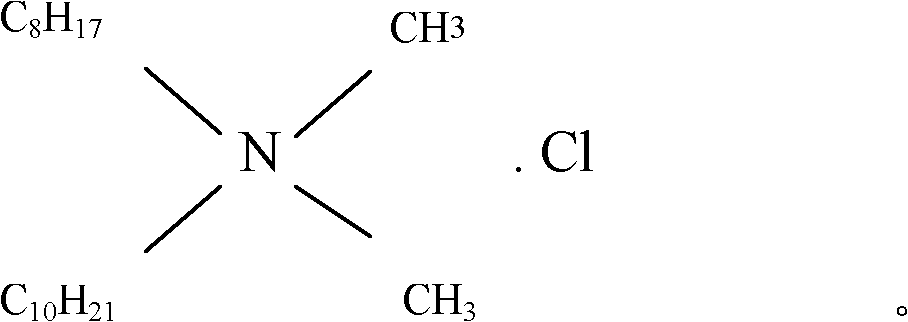

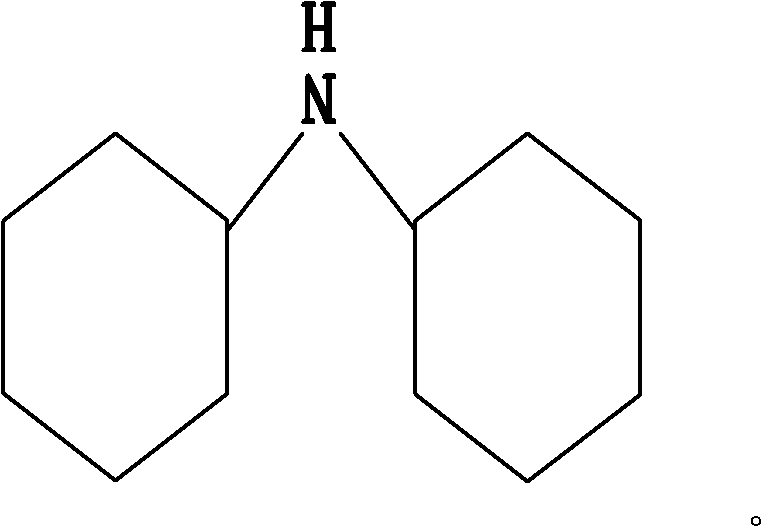

[0019] Take by weight percentage respectively: bis-octyl / decyl dimethyl ammonium chloride 20%, dicyclohexylamine 20%, triethanolamine mixture 16%, polymaleic anhydride 0.2%, ethanol 30% and water 13.8%, Wherein, triethanolamine mixture is made up of triethanolamine and monoethanolamine, and the weight ratio of triethanolamine and monoethanolamine is 3: 1; Add to a container, mix well, then add polymaleic anhydride, ethanol and water to the above container and continue to stir until the mixture of bis-octyl / decyl dimethyl ammonium chloride, dicyclohexylamine and triethanolamine Until it is completely dissolved in ethanol, a highly dispersed scale inhibitor for blast furnace gas residual pressure turbine power generation of the present invention is obtained.

Embodiment 2

[0021] Take by weight percentage respectively: bis-octyl / decyl dimethyl ammonium chloride 18%, dicyclohexylamine 18%, triethanolamine mixture 16%, polymaleic anhydride 0.4%, ethanol 30% and water 17.6%, Wherein, triethanolamine mixture is made up of triethanolamine and monoethanolamine, and the weight ratio of triethanolamine and monoethanolamine is 3: 1; Add to a container, mix well, then add polymaleic anhydride, ethanol and water to the above container and continue to stir until the mixture of bis-octyl / decyl dimethyl ammonium chloride, dicyclohexylamine and triethanolamine Until it is completely dissolved in ethanol, a highly dispersed scale inhibitor for blast furnace gas residual pressure turbine power generation of the present invention is obtained.

Embodiment 3

[0023] Take by weight percentage respectively: bis-octyl / decyl dimethyl ammonium chloride 16%, dicyclohexylamine 16%, triethanolamine mixture 16%, polymaleic anhydride 0.6%, ethanol 35% and water 16.4%, Wherein, triethanolamine mixture is made up of triethanolamine and monoethanolamine, and the weight ratio of triethanolamine and monoethanolamine is 3: 1; Add to a container, mix well, then add polymaleic anhydride, ethanol and water to the above container and continue to stir until the mixture of bis-octyl / decyl dimethyl ammonium chloride, dicyclohexylamine and triethanolamine Until it is completely dissolved in ethanol, a highly dispersed scale inhibitor for blast furnace gas residual pressure turbine power generation of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com