Antibacterial mouldproof biaxially oriented polylactic film and preparation method thereof

A biaxially stretched, antibacterial and anti-mildew technology, which is applied in the field of polylactic acid film, can solve the problems of weak anti-mold performance and poor water resistance, and achieve the effects of not easy to yellow and discoloration, high transparency, and good anti-bacterial and anti-mold effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

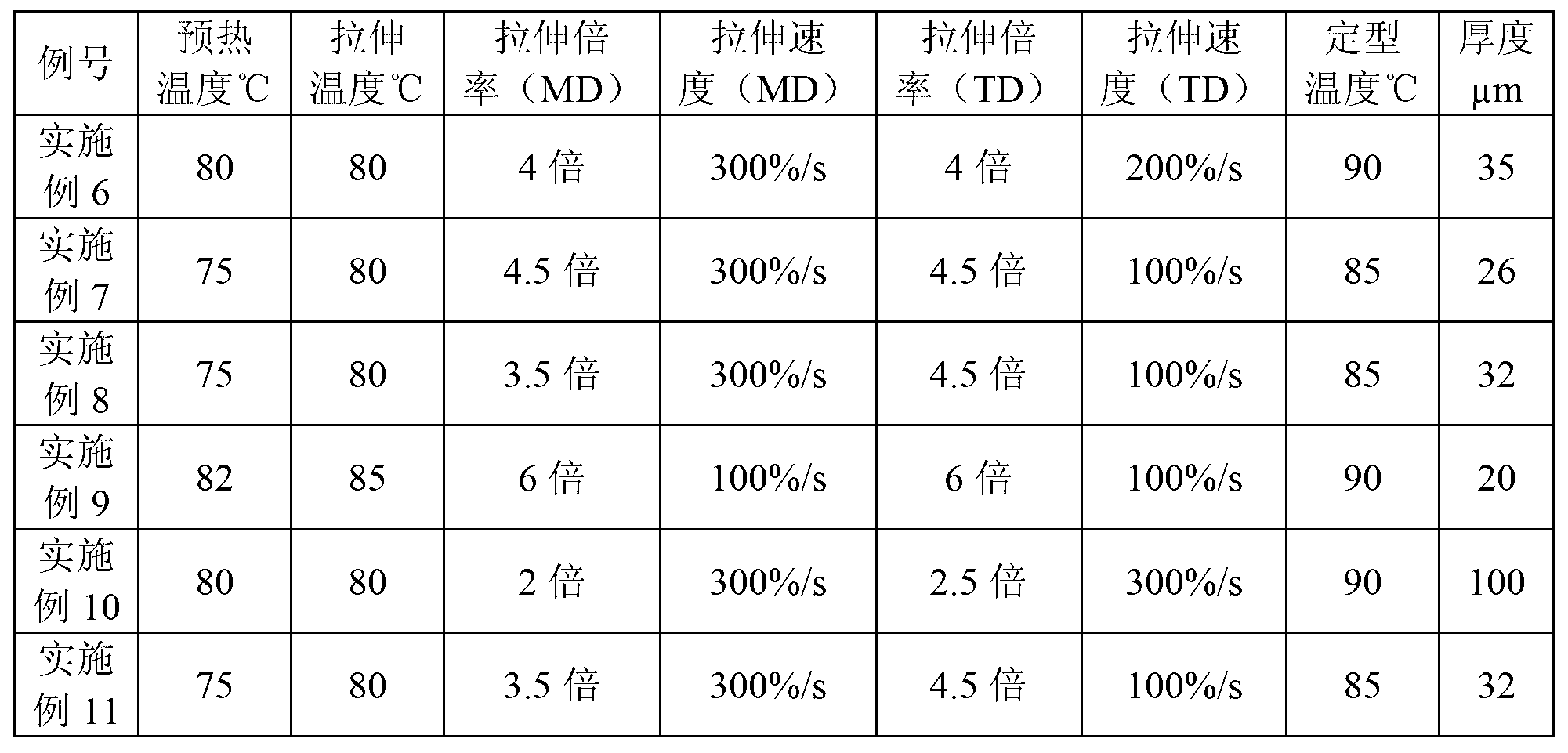

Examples

Embodiment 1

[0058] Weigh 21.0g (0.098mol) of polyhexamethylene guanidine propionate (Shanghai Gaoju F3000), add it to 200mL deionized water solution, stir to dissolve it; weigh another sodium pyrithione (Hangzhou Wanjing NPT) Add 20.0g (0.134mol) into 200mL deionized water, stir to dissolve; at room temperature (about 25°C), slowly pour polyhexamethylene guanidine propionate into the aqueous solution of sodium pyrithione, And keep stirring, after the mixing is complete, then fully stir for 20 minutes, dry and pulverize the product to obtain a completely substituted polyhexamethyleneguanidine pyrithione salt (antibacterial and antifungal agent 1#).

Embodiment 2

[0060] Weigh 20g (0.091mol) of polyhexamethylene biguanide hydrochloride (Shanghai Shande Industrial Co., Ltd. PHMB), add it to 200mL aqueous solution, stir to dissolve it; weigh another sodium pyrithione (Hangzhou Wanjing NPT) Add 35.0g (0.235mol) into 200mL of water, stir to dissolve; at 40°C, slowly pour polyhexamethylene biguanide hydrochloride into the aqueous solution of sodium pyrithione, and keep stirring to mix completely Afterwards, fully stir for another 20 minutes, dry and pulverize the product to obtain a completely substituted polyhexamethylene biguanide pyrithione (antibacterial and antifungal agent 2#).

Embodiment 3

[0062] Weigh 21.0g (0.133mol) of polyhexamethyleneguanidine hydrochloride (Shanghai Gaoju F1000), add it to 200mL aqueous solution, stir to dissolve it; and weigh 12.0g sodium pyrithione (Hangzhou Wanjing NPT) (0.080mol), added to 50mL water, stirred to dissolve; at room temperature (about 25°C), slowly pour the aqueous solution of sodium pyrithione into the polyhexamethyleneguanidine hydrochloride solution, and continuously Stir, after the mixing is complete, stir fully for another 20 minutes, dry and pulverize the product to obtain partially substituted polyhexamethyleneguanidine pyrithione salt (antibacterial and antifungal agent 3#).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com