Solvent or solvent composition for printing

A solvent composition and solvent technology, which can be used in applications, household appliances, inks, etc., can solve problems such as inconvenience of use, and achieve the effects of excellent solubility, low hygroscopicity, high efficiency and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

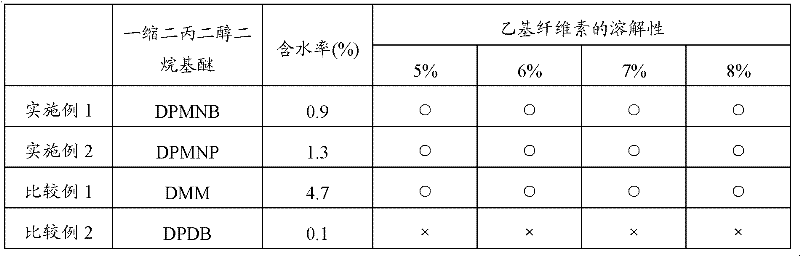

[0071] Add 20 g of dipropylene glycol methyl n-butyl ether (trade name "DPMNB", manufactured by DAICEL Chemical Industry Co., Ltd., hereinafter, sometimes referred to as "DPMNB") and 20 g of distilled water into a 50 mL flask, and stir for about 10 minutes. After standing still for 10 minutes, the water content of the organic phase was measured, and the water concentration in an environment of 25° C. was 0.9%.

[0072] The DPMNB was added to four 50mL flasks, 20.00g was added to each flask, and 1.05g of a product named "ETHOCEL" (registered trademark) (ethyl cellulose, manufactured by DOW Co., Ltd.) was added to each of them. (5% solution), 1.28g (6% solution), 1.51g (7% solution), 1.74g (8% solution). Then, it was stirred at 65° C., left to stand, and naturally cooled to 25° C., then the solubility of ethyl cellulose was observed with the naked eye, and evaluated according to the following criteria.

[0073] evaluation standard

[0074] Ethyl cellulose is completely dissolv...

Embodiment 2

[0077] Add 20 g of dipropylene glycol methyl n-propyl ether (trade name "DPMNP", manufactured by DAICEL Chemical Industry Co., Ltd., hereinafter, sometimes referred to as "DPMNP") and 20 g of distilled water into a 50 mL flask, and stir for about 10 minutes. After standing still for 10 minutes, the water content of the organic phase was measured, and the water concentration in an environment of 25° C. was 1.3%.

[0078] The solubility of ethyl cellulose was evaluated in the same manner as in Example 1 except that the above-mentioned DPMNP was used instead of DPMNB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com