Method for extracting and separating aromatic hydrocarbon and saturated hydrocarbon in catalytic cracking slurry oil

A technology for catalytic cracking of oil slurry and aromatic hydrocarbons is applied in the direction of multi-stage series-connected refining process treatment, etc., and can solve the problems of increasing the scale and processing capacity of the extraction device, adding a large amount of the second solvent, and increasing the cost input, etc. To achieve the effect of reducing processing capacity and operation difficulty, reducing consumption and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

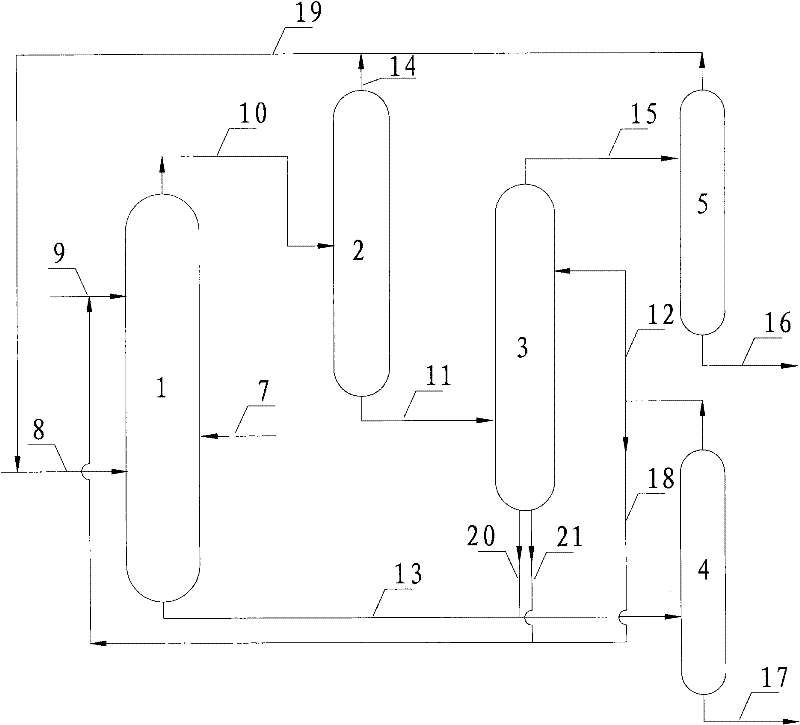

Method used

Image

Examples

example 1

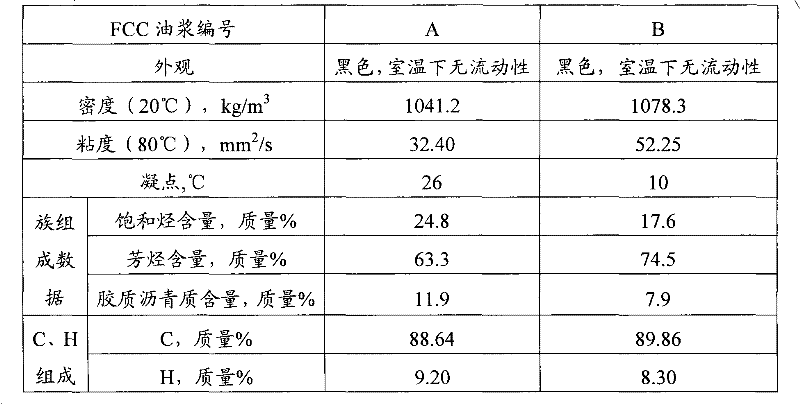

[0027] The catalytic cracking oil slurry A was taken as the separation object, and its properties are shown in Table 1.

[0028] At 60°C, add 100g of FCC oil slurry A, 150g of furfural, and 150g of n-octane into a separatory funnel, oscillate fully to mix evenly, and stand to separate into layers to obtain a raffinate phase and an extraction phase. Add 150g of n-octane to the extracted phase to simulate the operation of the second solvent entering the lower part of the first extraction tower, and the obtained n-octane layer is combined with the raffinate phase extracted for the first time to obtain a mixed raffinate phase. 300g of furfural was added therein for the second extraction operation; the obtained raffinate was then extracted with 300g of furfural for the third and fourth times respectively.

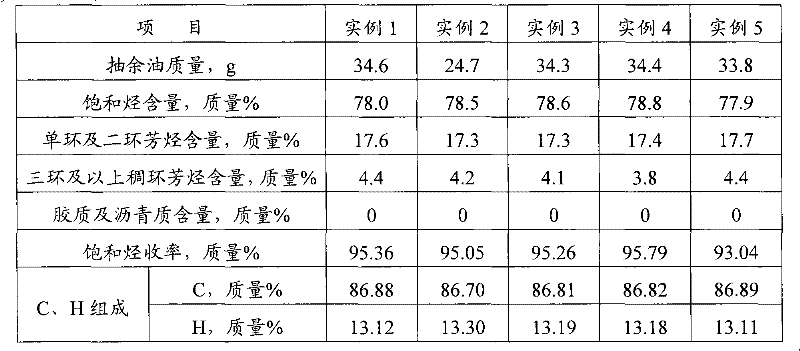

[0029] The raffinate after the fourth extraction was concentrated, and 250 g of n-octane was recovered by distillation under reduced pressure, and the quality of the raffinate w...

example 2

[0031] FCC oil slurry B is extracted and separated by the method of example 1, and the properties of FCC oil slurry B are shown in Table 1. Finally obtained raffinate oil 24.7g, its properties are shown in Table 2, and extracted oil 75.1g, its properties are shown in Table 3.

example 3

[0033] FCC oil slurry A is extracted and separated by the method of Example 1, except that the second solvent is changed from n-octane to n-heptane. Obtain raffinate oil 34.3g at last, its properties are shown in Table 2, and extracted oil 65.6g, its properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com