Ferriferous oxide nano-grade fiber, preparation method thereof, and purpose thereof

A ferric tetroxide and nanofiber technology, applied in chemical instruments and methods, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of reducing specific surface area, adverse adsorption or degradation of organic pollutants, etc. Surface area, superior magnetic properties, scientific effects of preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concrete steps of preparation are:

[0030] Step 1, first mix the soluble iron salt, citrate (or citric acid) and water according to the ratio of 1.2:2.1:35 by weight and then stir evenly; wherein, the soluble iron salt is ferric chloride, and the citrate is lemon Na2SO4, water is deionized water to obtain a mixed solution. Then add gelatin to the mixed liquid, wherein the weight ratio between the gelatin and the water in the mixed liquid is 0.2:35, and the hydrosol is obtained after the gelatin is completely dissolved.

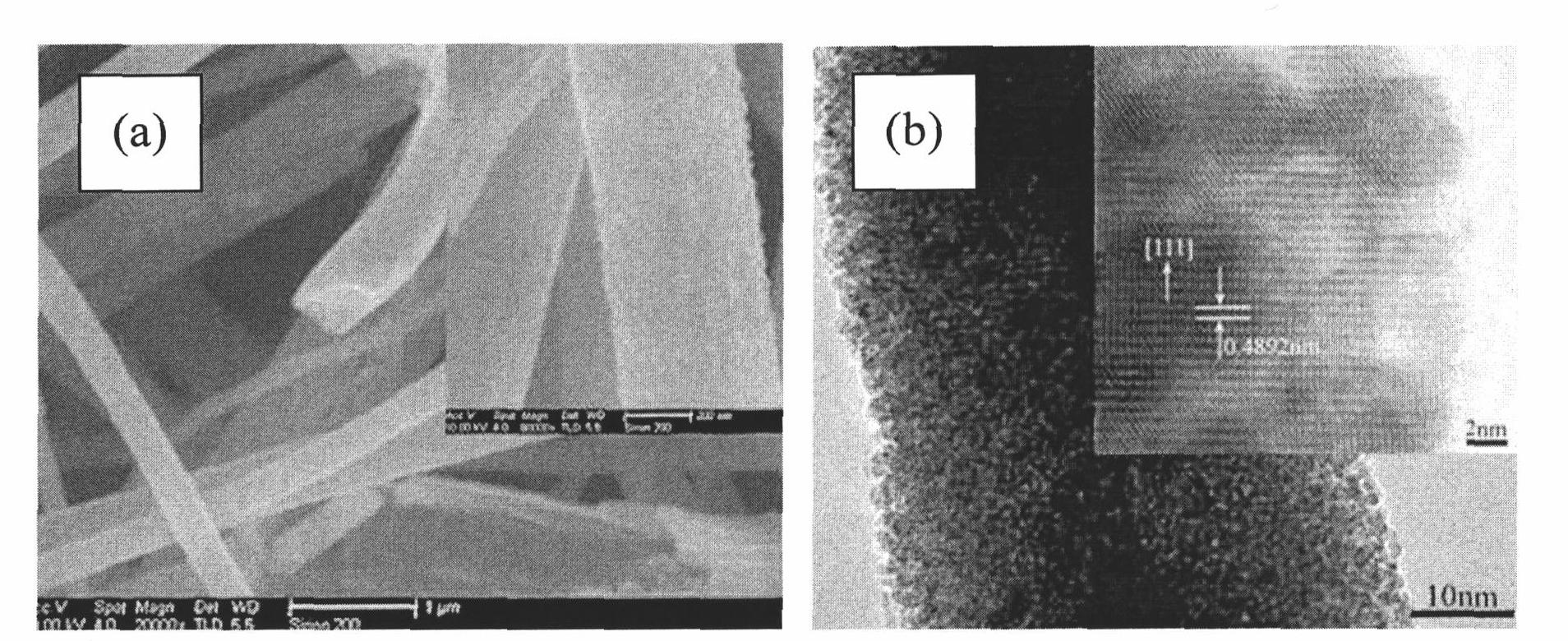

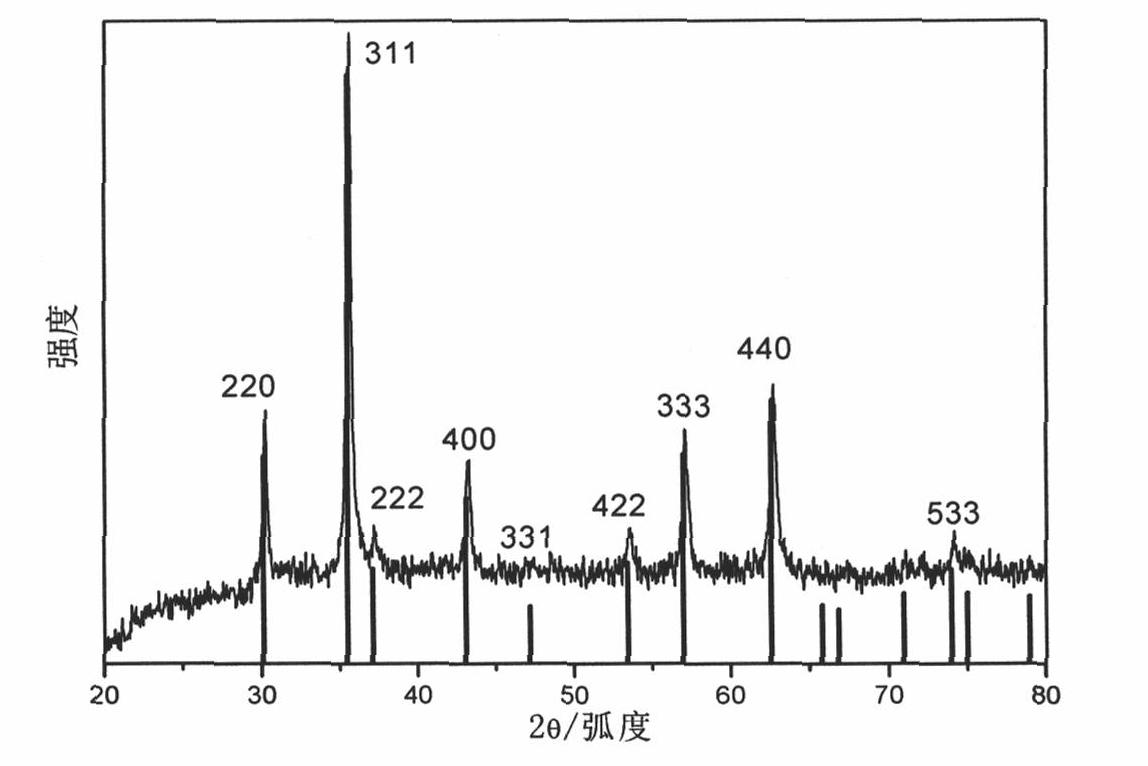

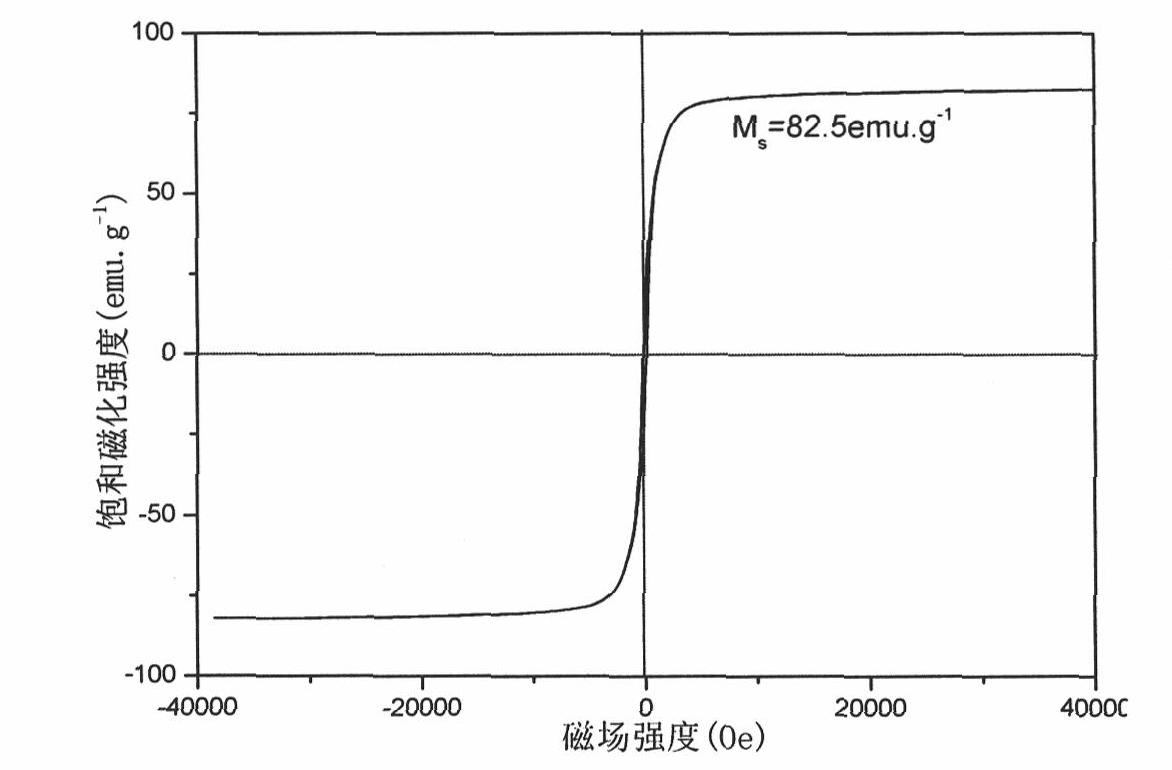

[0031] In step 2, the pH value of the hydrosol is first adjusted to 7 by using an alkali solution; wherein, the alkali solution is a sodium hydroxide solution to obtain a hydrosol precursor. Then put the hydrosol precursor in an airtight state and react at 180°C for 72 hours to obtain a product similar to figure 1 shown, and as figure 2 with image 3 Fe3O4 nanofibers shown in the curve.

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] Step 1, first mix the soluble iron salt, citrate (or citric acid) and water according to the ratio of 1.3:2.0:38 by weight and then stir evenly; wherein, the soluble iron salt is ferric chloride, and the citrate is lemon Na2SO4, water is deionized water to obtain a mixed solution. Then add gelatin to the mixed liquid, wherein the weight ratio between the gelatin and the water in the mixed liquid is 1:38, and the hydrosol is obtained after the gelatin is completely dissolved.

[0035] In step 2, an alkaline solution is used to adjust the pH value of the hydrosol to 7.3; wherein, the alkaline solution is a sodium hydroxide solution to obtain a hydrosol precursor. Then put the hydrosol precursor in an airtight state and react at 195°C for 55h to obtain a product similar to figure 1 shown, and as figure 2 with image 3 Fe3O4 nanofibers shown in the curve.

Embodiment 3

[0037] The concrete steps of preparation are:

[0038] Step 1, first mix the soluble iron salt, citrate (or citric acid) and water according to the ratio of 1.4:1.9:40 by weight and then stir evenly; wherein, the soluble iron salt is ferric chloride, and the citrate is lemon Na2SO4, water is deionized water to obtain a mixed solution. Then add gelatin to the mixed liquid, wherein the weight ratio between the gelatin and the water in the mixed liquid is 2:40, and the hydrosol is obtained after the gelatin is completely dissolved.

[0039] In step 2, an alkaline solution is used to adjust the pH value of the hydrosol to 7.5; wherein, the alkaline solution is a sodium hydroxide solution to obtain a hydrosol precursor. Then put the hydrosol precursor in an airtight state and react at 210°C for 38 hours to obtain a product similar to figure 1 shown, and as figure 2 with image 3 Fe3O4 nanofibers shown in the curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com