Fast oxidizing agent for calcium sulfite in desulfurization gypsum and application of fast oxidizing agent

A technology of desulfurized gypsum and calcium sulfite, which is applied in the field of building materials, can solve problems such as inconvenient popularization and use, adverse effects on cement performance, and excessive water introduction, and achieves the effects of simple operation, economical reliability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

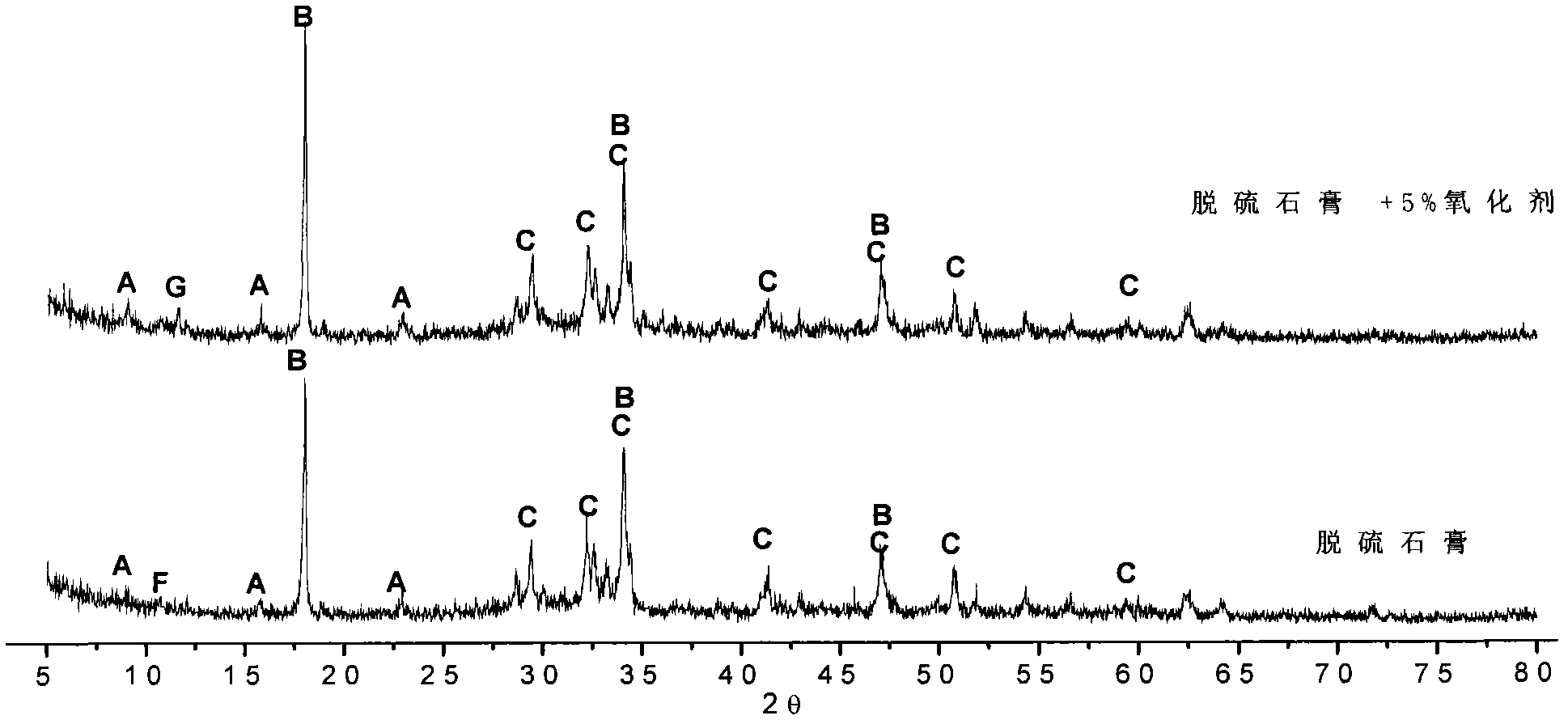

[0026] Example 1. Preparation of rapid oxidant of calcium sulfite in desulfurized gypsum and detection of its desulfurization effect

[0027] Get 3.75 grams (10 parts) of commercially available technical grade potassium permanganate, 0.75 grams (2 parts) of commercially available technical grade acetic acid, 16.5 grams (44 parts) of ferromanganese alloy slag, 16.5 grams (44 parts) of pyrite slag, mix The composite oxidizing agent of this example is prepared uniformly.

[0028]

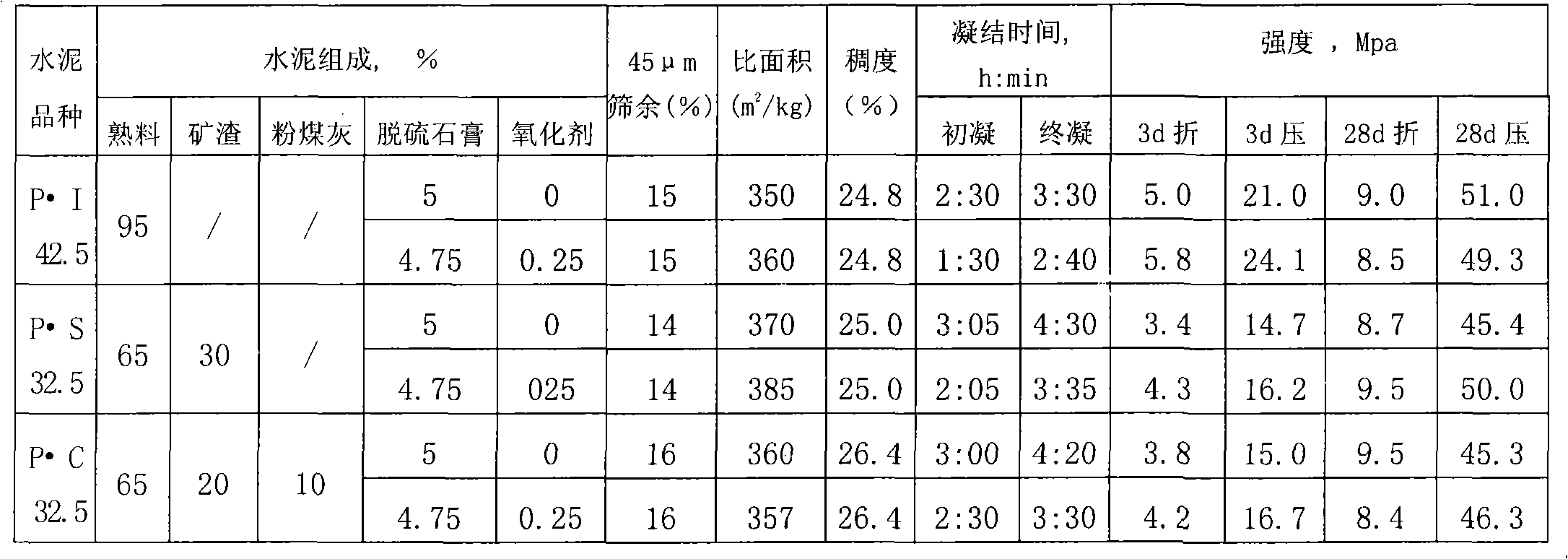

[0029] Using cement performance comparison test:

[0030] Raw materials: cement clinker; desulfurized gypsum (purchased from coal-fired power plants), calcium sulfite (CaSO 3 0.5H 2 O) content is about 10%; fly ash meets the requirements of GB / T 1596 (level II); slag meets the requirements of GB / T 203.

[0031] Concrete method: take above-mentioned composite oxidant, mix uniformly with desulfurization gypsum according to the addition ratio of 5% of total mass content (composite oxidant 1 part, de...

Embodiment 2~ Embodiment 5

[0036] Example 2-Example 5, preparation of rapid oxidant of calcium sulfite in desulfurization gypsum and detection of desulfurization effect

[0037]According to the sample preparation and detection method in Example 1, the ratio of composite oxidant raw materials was changed (as shown in Examples 2 to 5 in Table 2), and the oxidation effect of calcium sulfite in desulfurized gypsum was compared.

[0038] The results are shown in Table 2. It can be seen that the physical properties of cement after oxidation treatment of desulfurized gypsum are improved, the setting time of cement is shortened, and the early and late strength There are different degrees of improvement; and the ratio of composite oxidant raw materials changes, and the difference in cement performance is not large, which further proves that the oxidant of the present invention has a relatively stable oxidation effect on calcium sulfite.

[0039] Table 2 Variation of oxidant ratio and comparison of desulfurized c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com