Liquid chromatography method for determining carbonyl compound content in methylrhenium trioxide (MTO) aqueous product

A technology of carbonyl compounds and liquid chromatography, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not being able to provide the type of carbonyl compounds and the content of monomer components, and achieve a good linear relationship, high sensitivity, and accurate quantification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

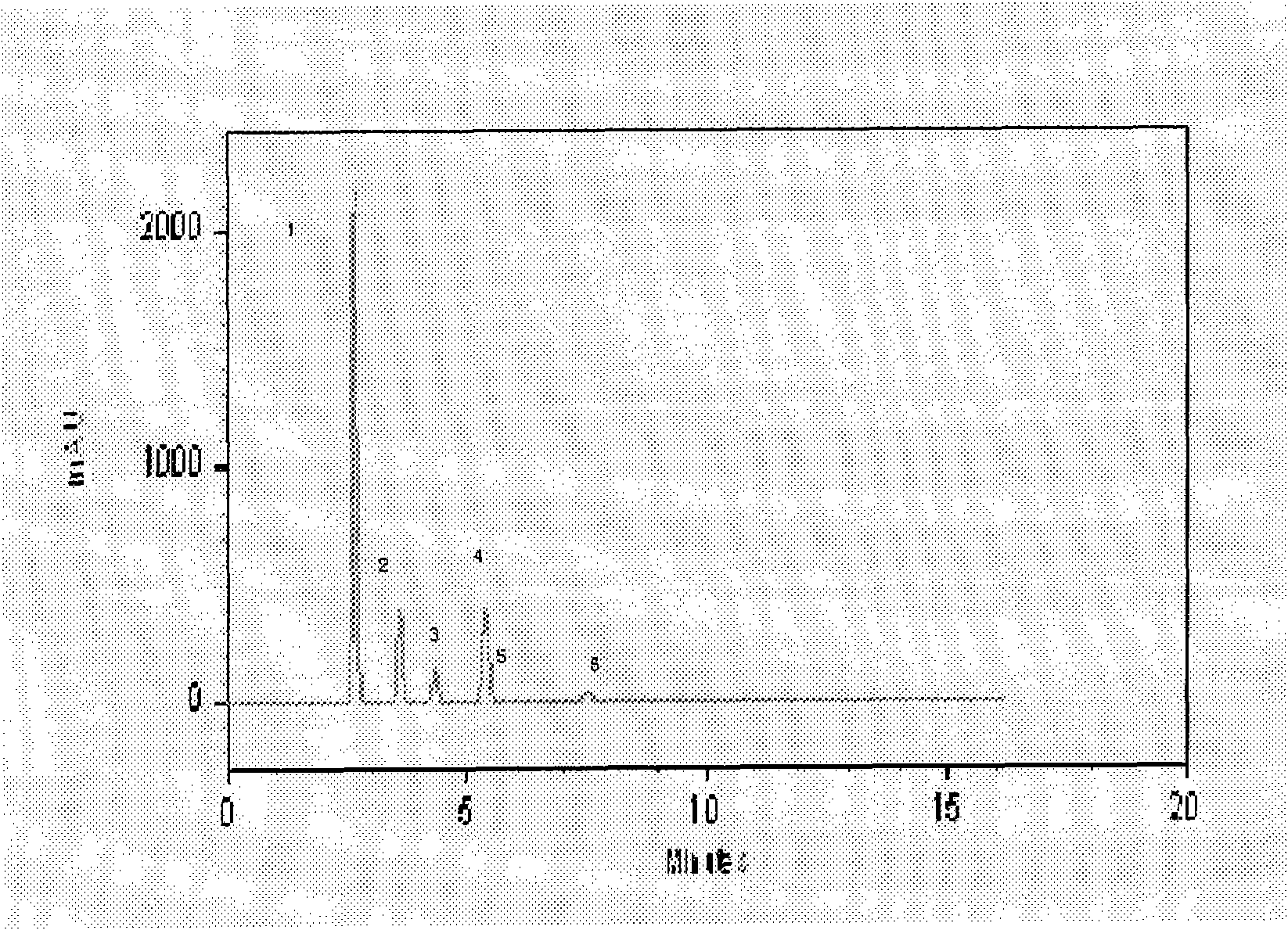

Image

Examples

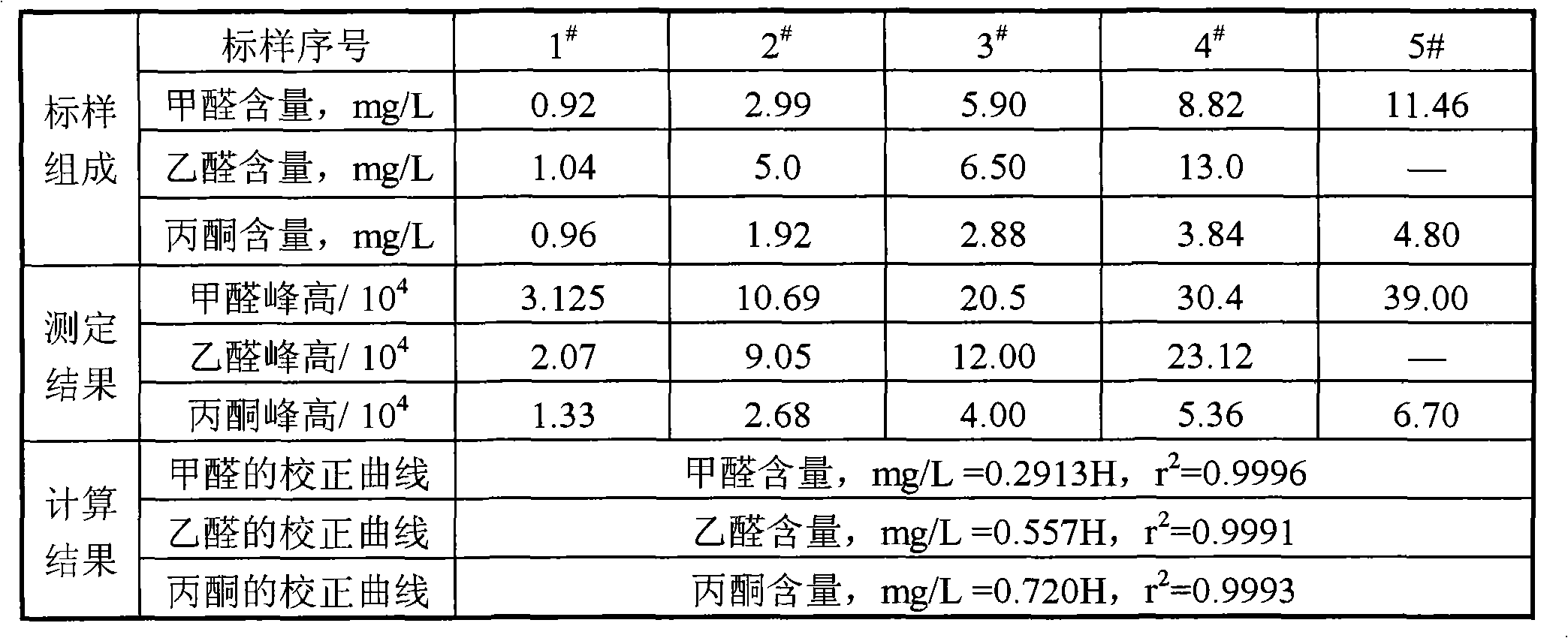

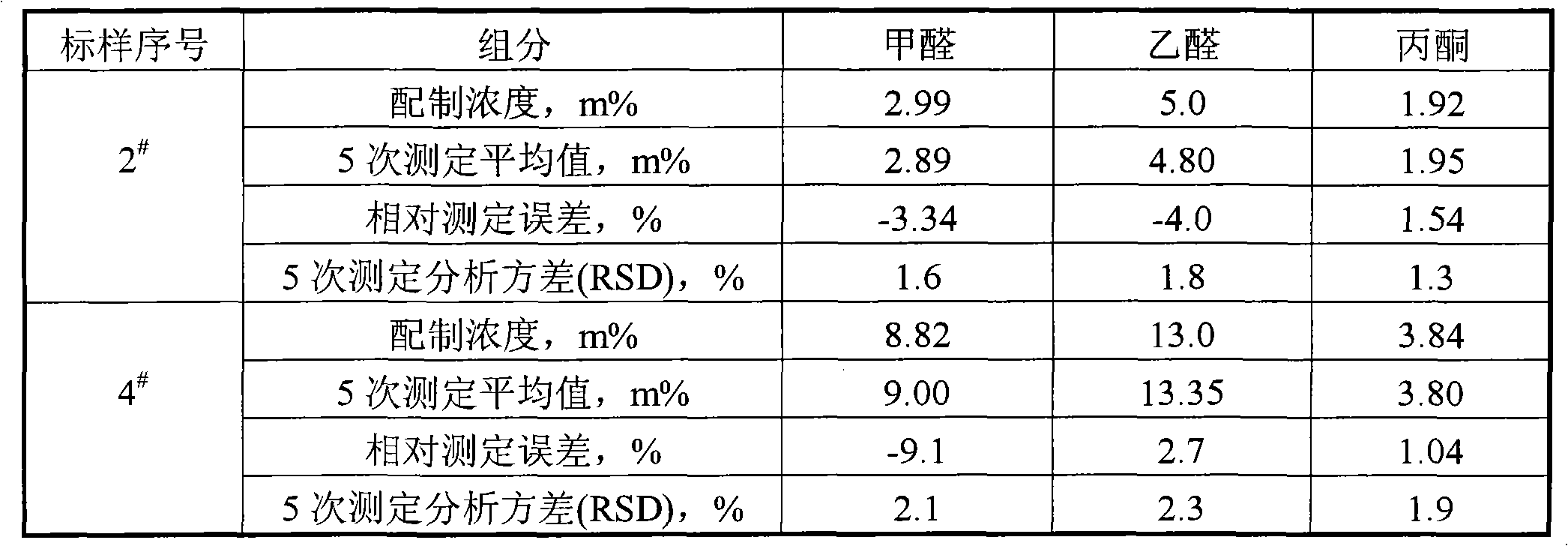

Embodiment 1

[0013] According to the analysis steps of the content of the invention, a series of standard samples containing formaldehyde and acetaldehyde are analyzed, (a) preparing formaldehyde, acetaldehyde and acetone series standard solutions. First calibrate the content of formaldehyde solution (~37% aqueous solution) according to the method specified in GB / T 9009-1998, then weigh about 100μL of formaldehyde solution, place it in a 50mL volumetric flask, then dilute with water to the mark, and shake well. Use a pipette to accurately draw 1.00 mL of the solution into a 100 mL volumetric flask, then dilute to the mark with water, shake well for later use, and calculate the formaldehyde content of the standard solution, expressed in μg / mL. Pipette 1.00mL, 2.00mL, 3.00mL, 4.00mL and 5.00mL of formaldehyde standard solutions into 25mL volumetric flasks respectively; prepare a series of standard solutions of acetaldehyde and acetone; (b) prepare 2,4-dinitrophenylhydrazine Derivatizer. Wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com