Regeneration method for waste liquor of all-vanadium flow battery

An all-vanadium redox flow battery and electrolytic waste liquid technology, which is applied in the field of regeneration of all-vanadium redox flow battery waste liquid, can solve the problems of high energy consumption, waste, and complicated processes in the electrolysis process, and solve the waste of vanadium raw materials and environmental pollution. Problems, slow capacity decay, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The present invention will be described in more detail with reference to Examples, but the present invention is not limited to these Examples.

[0022] First, the method of determining the addition amount of the reducing agent in Examples, ie, titration experiment, is described.

[0023] Titration experiment

[0024] The process of battery operation is to first put VOSO 4 Solution, placed on the positive electrode of the electrolytic cell, and the negative electrode is also the same amount of VOSO 4 Solution, the valence state of V is 4, and the current is passed through. After a period of time, the negative electrode solution becomes a 3-valent electrolyte, that is, V 3+ of sulfuric acid solution. The positive electrode solution is a pentavalent electrolyte. The power-on time is calculated according to the formula: I*t=V*M*96500, where I is the current intensity, t is the time, M is the molar concentration of pentavalent vanadium cations in the electrolyte, V is th...

Embodiment 1

[0039] Solid VOSO 4 Prepared as 1.5mol / L VOSO 4 The solution is filtered with a vacuum pump. The filter hole of the polytetrafluoroethylene filter membrane in the filter is 1 μm, and the VOSO can be removed by filtration. 4 Silicon compound impurities brought in during the production process to obtain 1.5mol / L VOSO 4 solution.

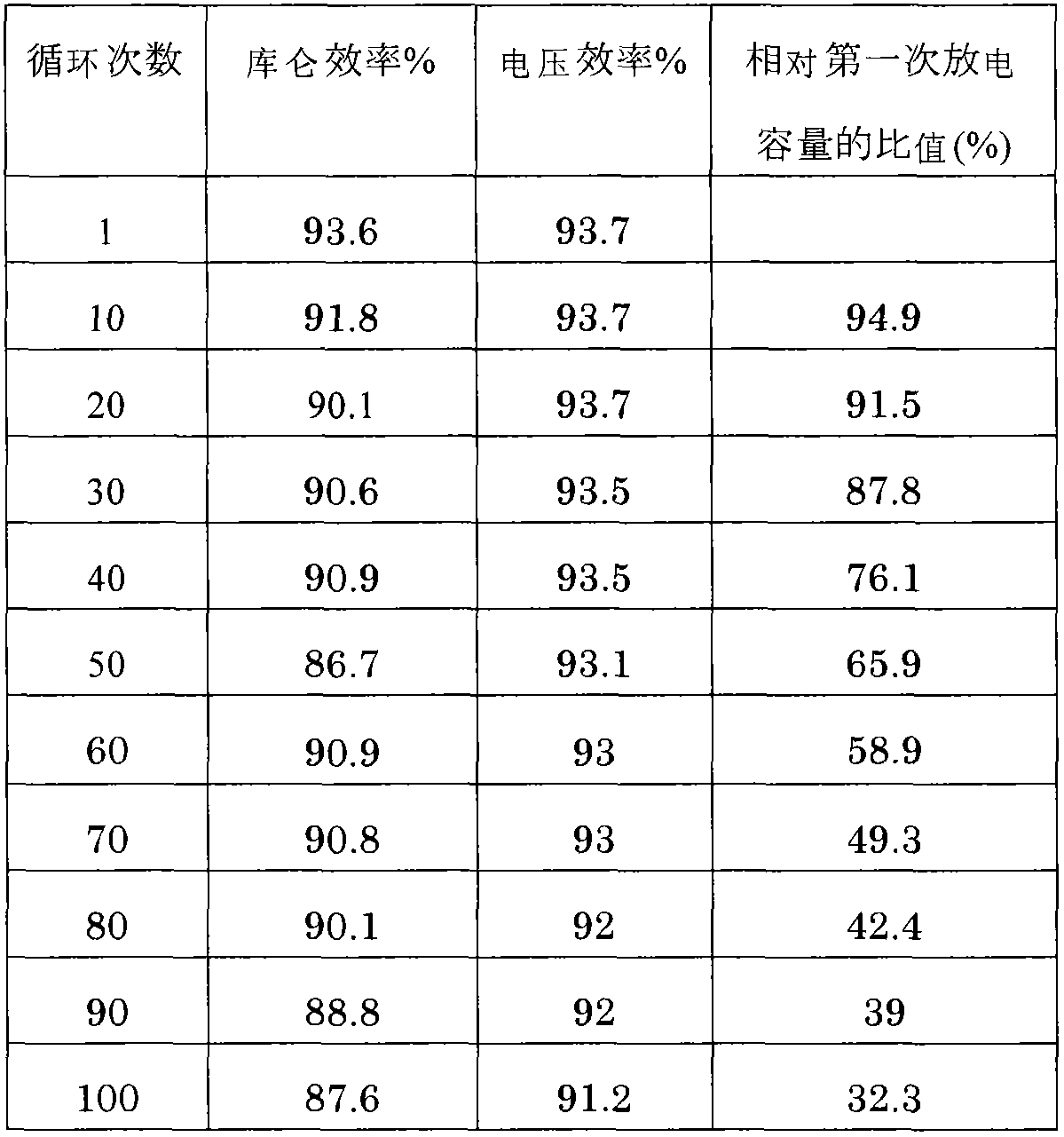

[0040] 1 liter of VOSO with a concentration of 1.5mol / L 4 The solution is placed in the positive electrolyte storage tank of the battery, and the same amount of VOSO 4 The solution is placed in the negative electrode electrolyte storage tank, the electrode material of the battery is polyacrylonitrile-based carbon felt, and the electrode area is 100cm 2 , the diaphragm is Nafion117 ion exchange membrane; the current collector is a carbon plate. The electrolyte tank is placed outside the battery and pumped into the battery. Constant current electrolysis, the current density is 50mA / cm 2 . After 8 hours, the negative electrode solution becomes a t...

Embodiment 2

[0047] Solid VOSO 4 Prepared as 1.5mol / L VOSO 4 The solution is filtered with a vacuum pump. The filter hole of the polytetrafluoroethylene filter membrane in the filter is 1 μm, and the VOSO can be removed by filtration. 4 Silicon compound impurities brought in during the production process to obtain 1.5mol / L VOSO 4 solution.

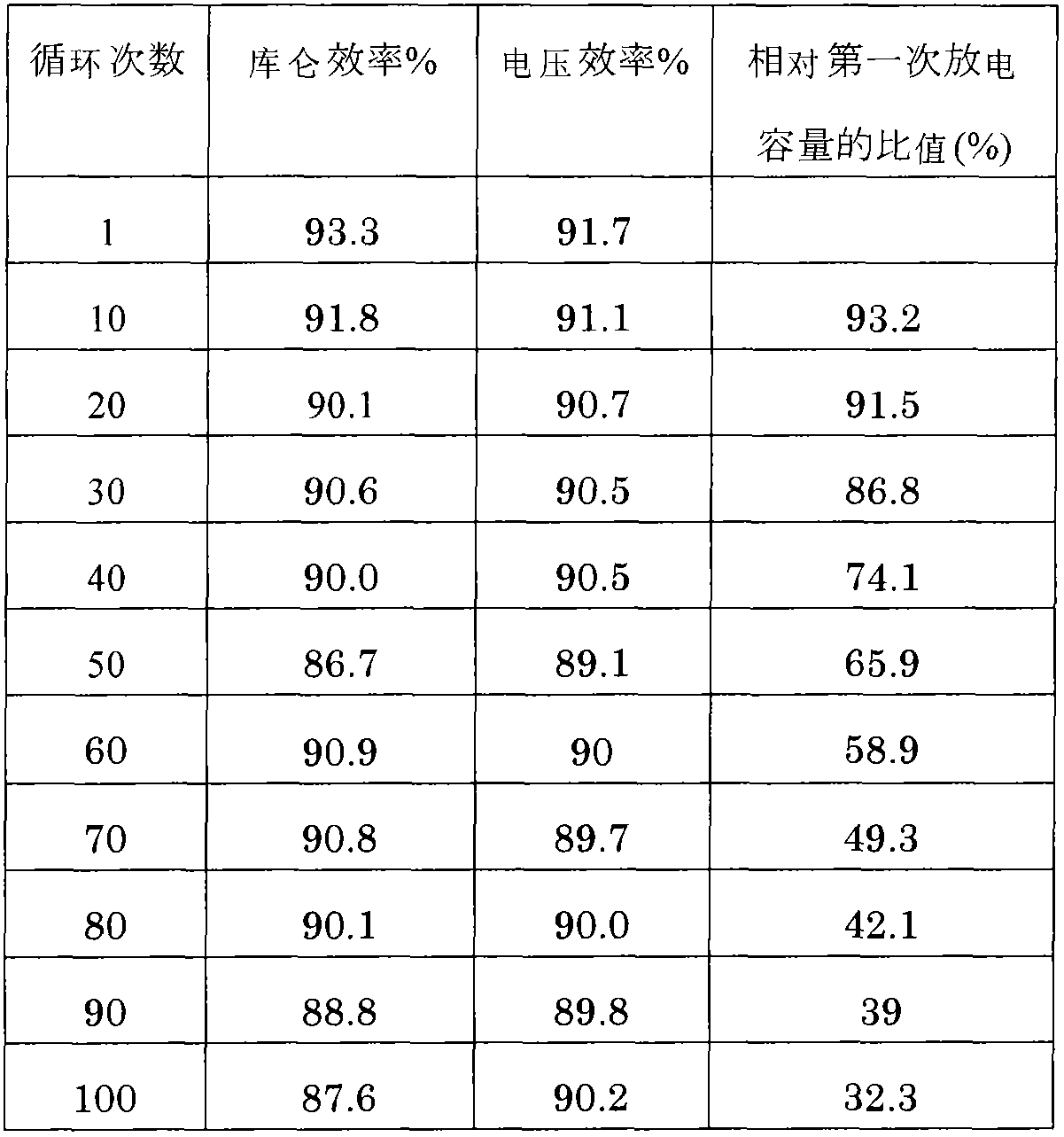

[0048] 1 liter of VOSO with a concentration of 1.5mol / L 4 Solution, placed in the positive electrode electrolyte liquid storage tank of the electrolytic battery, and the negative electrode is also the same amount of VOSO 4 solution, the electrode material of the battery is polyacrylonitrile-based carbon felt, and the electrode area is 100cm 2 .The diaphragm is Nafion117 ion exchange membrane; the current collector is a carbon plate. The electrolyte tank is placed outside the battery and pumped into the battery. Constant current electrolysis, the current density is 40mA / cm 2 . After 5 hours, the negative electrode solution becomes a 3.5-valent e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com