Modified titanium silicate molecular sieve material and preparation method thereof

A titanium-silicon molecular sieve and modification technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of weak acidity, absence of titanium-silicon molecular sieves, low catalytic oxidation performance, etc. Effects of increased performance, increased added value, strong reactivity and product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get the titanium-silicon molecular sieve of 10 gram hollow grains, 8.2 gram crystallization aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O and 4.2 g of magnesium chloride hexahydrate MgCl 2 ·6H 2 O was added into a mortar, ground and mixed, then transferred to a crucible, transferred to a muffle furnace, and roasted at 550°C for 4 hours, and the product was recovered to obtain the modified titanium-silicon molecular sieve material of the present invention (abbreviated as xMgO-yAl 2 o 3 -HTS), x=0.081, y=0.11.

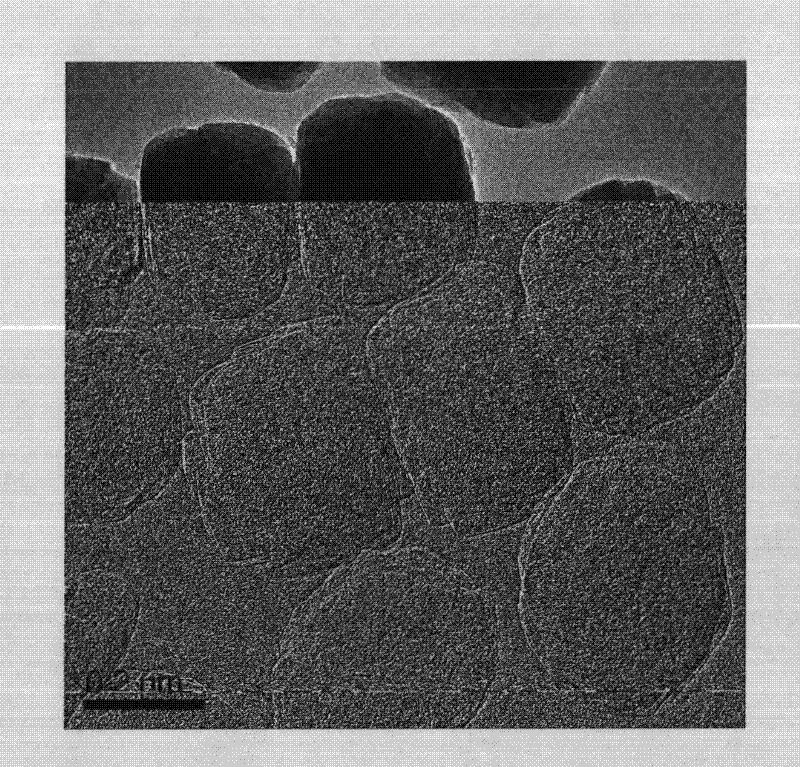

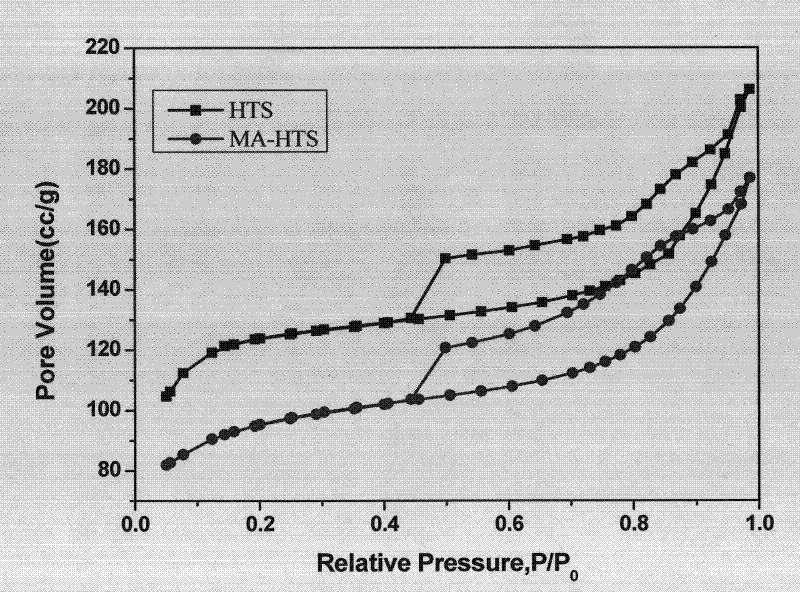

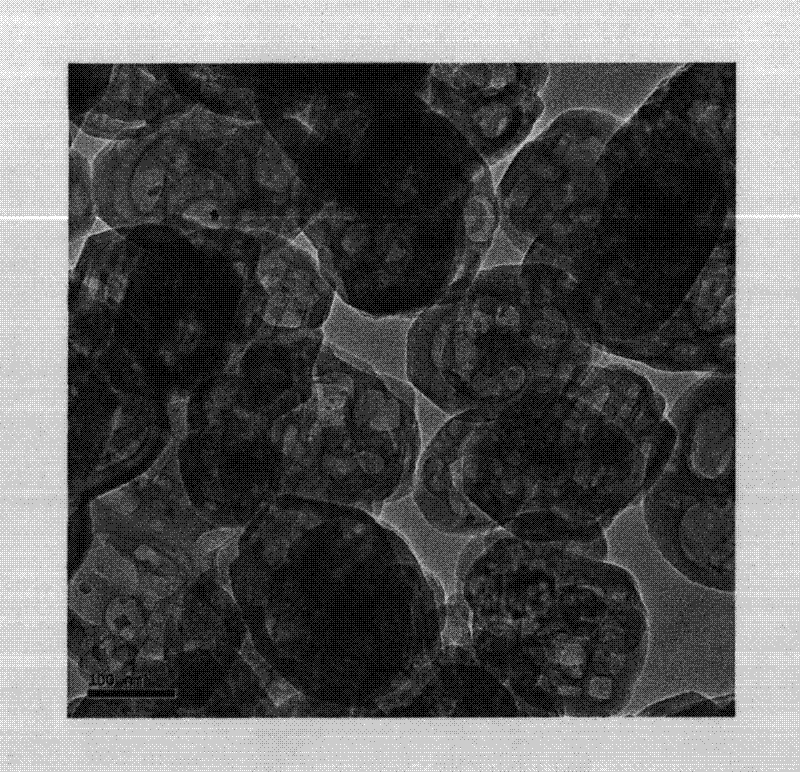

[0027] The adsorption-desorption isotherm curve of the low-temperature nitrogen adsorption of this material has a hysteresis loop ( figure 2 Middle MA-HTS curve), transmission electron micrographs show that it is a hollow structure ( image 3 ).

Embodiment 2

[0029] Get the titanium-silicon molecular sieve of 10 gram hollow grains, 7.4 gram crystallization aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O and 8.0 g of magnesium chloride hexahydrate MgCl 2 ·6H 2 O is added to a mortar, ground and mixed, then transferred to a crucible, transferred to a muffle furnace, roasted at 550°C for 4 hours, and the product is recovered to obtain the xMgO-yAl of the present invention 2 o 3 - HTS material, x=0.134, y=0.097.

[0030] The adsorption-desorption isotherm curve of the low-temperature nitrogen adsorption of the material has figure 2 The characteristics of the hysteresis loop of the MA-HTS curve in the middle, transmission electron micrographs show that there is image 3 Characteristics.

Embodiment 3

[0032]Get the titanium-silicon molecular sieve of 10 gram hollow grains, 5.6 gram crystalline nonahydrate aluminum nitrate Al(NO 3 ) 3 9H 2 O and 3.8 g of magnesium chloride hexahydrate MgCl 2 ·6H 2 O is added to a mortar, ground and mixed, then transferred to a crucible, transferred to a muffle furnace, roasted at 550°C for 4 hours, and the product is recovered to obtain the xMgO-yAl of the present invention 2 o 3 - HTS material, x=0.076, y=0.074.

[0033] The adsorption-desorption isotherm curve of the low-temperature nitrogen adsorption of the material has figure 2 The characteristics of the hysteresis loop of the MA-HTS curve in the middle, transmission electron micrographs show that there is image 3 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com