Medicinal sodium chloride production process

A production process, sodium chloride technology, applied in the field of pharmaceutical sodium chloride production process, can solve problems affecting the storage and transportation of sodium chloride, non-conforming to pharmaceutical grade, etc., achieve stable product quality and reduce production costs , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Production of medicinal sodium chloride:

[0020] 1. Saltification: Add drinking water and mother liquor to barrel A, turn on and stir, add 1200g of industrial salt, add 25g of barium chloride after dissolving, heat to boiling with steam, let it settle for 25 minutes, take a sample for detection, and the inspection shows that, Slight excess of barium salt, no sulfate. After the feed liquid is precipitated, the supernatant is taken into barrel B, 40g of sodium carbonate is added, heated to 105°C and boiled, and the sample is tested, and the pH value is 7.0, free of calcium, magnesium, and barium salts.

[0021] 2. Filtration and acid adjustment: put the qualified material liquid in barrel B into the acid adjustment tank after coarse filtration and fine filtration. After the medium feed solution is confirmed to be clear, add 3 L of hydrochloric acid to adjust the pH value to 4.5.

[0022] 3. Evaporation: pump the acid-adjusted material liquid in the acid-adjusting tank ...

Embodiment 2

[0025] The preparation method of medicinal sodium chloride provided by the invention, its quality control standard is based on "Chinese Pharmacopoeia 2010 edition (two)" and enterprise standards. The standards are as follows:

[0026] 1. Properties: This product is colorless, transparent cubic crystal or white crystalline powder; odorless and salty. This product is soluble in water, almost insoluble in ethanol.

[0027] 2. Identification: This product shows the identification reaction of sodium salt and chloride.

[0028] 3. pH: Take 5.0g of this product, add 50mL of water to dissolve it, add 2 drops of bromothymol blue indicator solution, if it turns yellow, add 0.10mL of sodium hydroxide titration solution (0.02mol / L), and it will turn blue; If it is blue or green, add hydrochloric acid titration solution (0.02mol / L), and it should turn yellow.

[0029] 4. Clarity and color of the solution: Take 5.0g of this product, add 25mL of water to dissolve, and the solution should ...

Embodiment 3

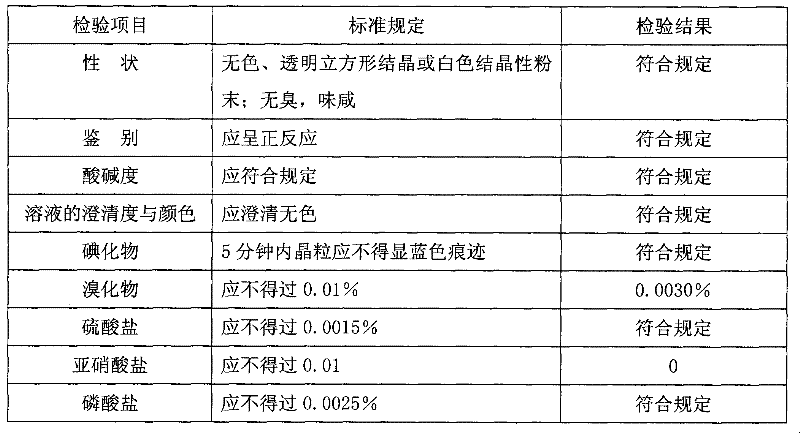

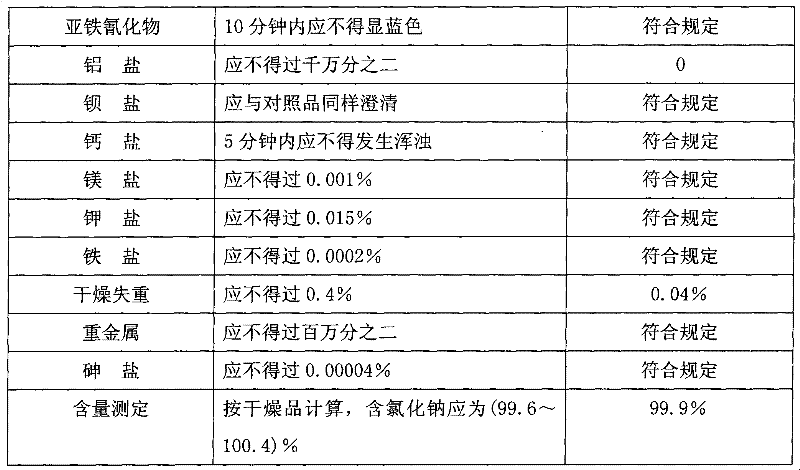

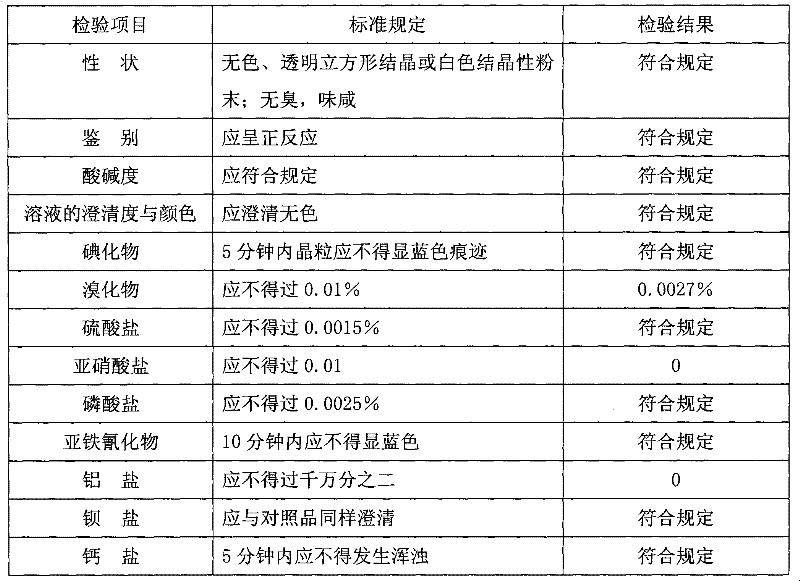

[0047] According to the production technique provided by the invention, the sodium chloride that production batch is 10.000t, according to " Chinese Pharmacopoeia 2010 edition (two) " and enterprise standard inspection, its inspection result is as follows:

[0048]

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com