Treatment process of circulating cooling water with leaked ammonia nitrogen

A technology of circulating water and ammonia nitrogen, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of controlling bacteria, reducing nutrient sources, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

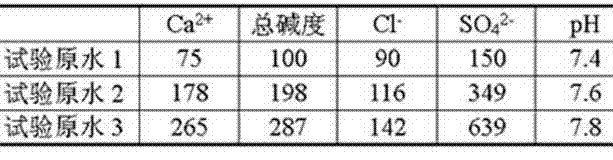

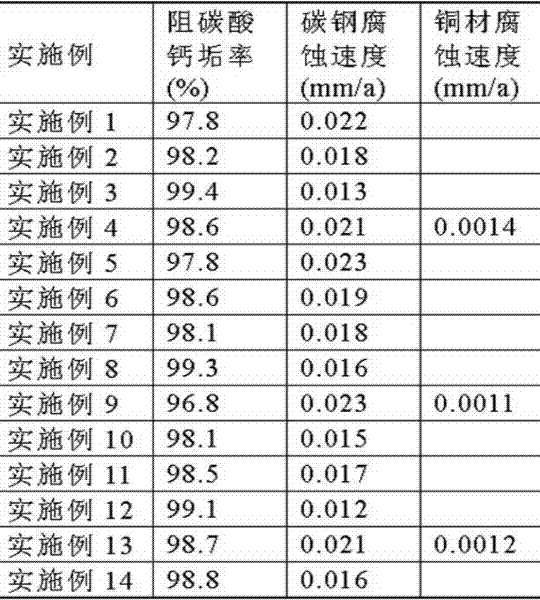

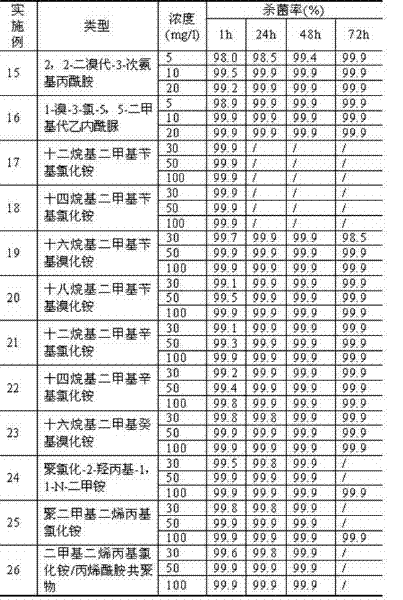

Examples

Embodiment 1

[0037] Prepare 100g medicine solution

[0038] Preparation process: Weigh 50g of sodium borate decahydrate and dissolve it in 42.25g of water, stir to dissolve, then add 3.33g of which the limiting viscosity is 0.072dL·g -1 , polyepoxysuccinic acid with a solid content of 30%, and finally add 4.42g of zinc sulfate heptahydrate and 10 drops of dilute sulfuric acid of 1:3 (volume ratio of concentrated sulfuric acid to water), fully dissolve, shake well, and obtain the required Prepared 100g medicament solution.

[0039] Add the prepared medicament solution to the test water 1 at a medicament concentration of 200mg / L, borate, polyepoxysuccinic acid, Zn 2+ The effective concentrations are 100mg / L, 2mg / L, and 2mg / L, respectively. The pH of the solution was then adjusted and stabilized at 8.7 with 4% NaOH.

Embodiment 2

[0041] Prepare 100g medicine solution

[0042] Preparation process: Weigh 50g of sodium gluconate and dissolve it in 21.12g of water, stir to dissolve, then add 26.67g of which the limiting viscosity is 0.070dL·g -1 1. Polymaleic anhydride with a solid content of 30%, finally add 2.21g of zinc sulfate heptahydrate and 10 drops of dilute sulfuric acid (volume ratio of concentrated sulfuric acid to water) 10 drops, fully dissolve, shake well, and obtain the required preparation 100g of medicament solution.

[0043] When the prepared drug solution is added to the test water 1 at a drug concentration of 100mg / L, the water gluconate, polymaleic anhydride, Zn 2+ The effective concentrations are 50mg / L, 8mg / L, and 0.5mg / L, respectively. The pH of the solution was then adjusted and stabilized at 8.7 with 4% KOH.

Embodiment 3

[0045] Prepare 100g medicine solution

[0046] Preparation process: Weigh 25g of sodium silicate and dissolve in 21.12g of water, stir to dissolve, then add 25g of sodium gluconate and 26.67g of limiting viscosity to 0.071dL·g -1 , methyl acrylate / styrene sulfonic acid copolymer with a solid content of 30% (the mass ratio of methyl acrylate / styrene sulfonic acid is 2:1), and finally add 3.14g of zinc chloride and 1:3 (concentrated sulfuric acid and water volume ratio) of dilute sulfuric acid 10 drops, fully dissolved, shaken, that is, to obtain the required preparation of 100g drug solution.

[0047] When the prepared drug solution is added to the test water 1 at a drug concentration of 100 mg / L, silicate, gluconate, methyl acrylate / styrene sulfonic acid copolymer, Zn 2+ The effective concentrations are 25mg / L, 25mg / L, 8mg / L, 1.5mg / L respectively. The pH of the solution was then adjusted and stabilized at 8.7 with 4% NaOH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com