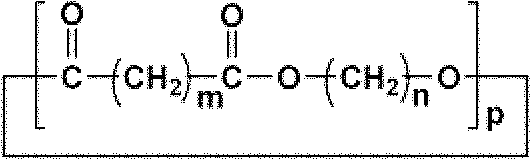

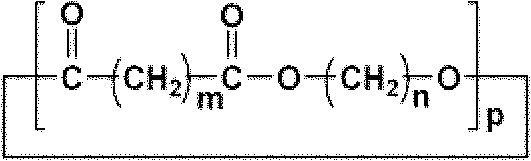

Aliphatic/aromatic copolyester and preparation method thereof

An aromatic and copolyester technology, applied in the field of aliphatic/aromatic copolyester and its preparation, can solve problems such as incompatibility, achieve excellent mechanical properties, overcome poor mechanical properties, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 1.46kg of dimethyl terephthalate (DMT), 1.35kg of 1,4-butanediol, and 1.5g of tetra-n-butyl titanate into a 10L reaction kettle. After all the materials are added, fill with nitrogen and deflate to remove the oxygen in the reaction kettle. To ensure that the transesterification reaction is carried out under nitrogen conditions. The transesterification reaction was stirred at 230° C. for 3 h. During this process, methanol was distilled out from the reaction mixture as a by-product until the amount of the distillate reached 92% of the theoretically calculated amount. (The theoretically calculated amount of methanol is twice the molar amount of DMT)

[0046] Add 0.87kg of cyclic ethylene glycol oxalate and 3g of dibutyltin oxide, control the reaction temperature to 250°C, keep the temperature for 2h, then vacuumize (<500Pa) and stir for 2.5h to stop the reaction.

[0047] Inflate nitrogen to pressurize, extrude the reaction mixture from the reaction kettle, cool and ...

Embodiment 2

[0050] Add 0.83kg of terephthalic acid (PTA), 1.20kg of ethylene glycol, and 2.0g of antimony trioxide into a 10L reaction kettle. After all the materials are added, fill with nitrogen and deflate to remove the oxygen in the reaction kettle. To ensure that the esterification reaction is carried out under nitrogen conditions. The esterification reaction was stirred at 200° C. for 4 h. During this process, water was distilled out from the reaction mixture as a by-product until the amount of the distillate reached 92% of the theoretically calculated amount. (The theoretically calculated amount of water is twice the molar amount of PTA)

[0051] Add 2.0 kg of cyclic butanediol adipate and 4 g of stannous octoate, control the reaction temperature to 260° C., keep the temperature for 1.5 hours, vacuumize (<500 Pa) and stir for 2 hours to stop the reaction.

[0052] Inflate nitrogen to pressurize, extrude the reaction mixture from the reaction kettle, cool and shape in water, and o...

Embodiment 3

[0055] 1.89 kg of dimethyl terephthalate (DMT), 0.44 kg of dimethyl isophthalate, 2.2 kg of 1,3-propanediol, and 2.3 g of zinc acetate were added to a 10 L reactor. After all the materials are added, fill with nitrogen and deflate to remove the oxygen in the reaction kettle. To ensure that the transesterification reaction is carried out under nitrogen conditions. The transesterification reaction was stirred at 220° C. for 3.5 h. During this process, methanol was distilled out from the reaction mixture as a by-product until the amount of the distillate reached 92% of the theoretically calculated amount. (The theoretically calculated amount of methanol is twice the molar amount of dimethyl phthalate)

[0056] Add 0.52kg of cyclic butanediol succinate, 2g of dibutyltin oxide, and 1g of aluminum triisopropoxide, control the reaction temperature at 260°C, keep the temperature for 1.5h, then vacuumize (<500Pa) and stir for 3h to stop the reaction.

[0057] Inflate nitrogen to pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com