Harvesting and processing technology for producing edible alfalfa powder

A processing technology and technology of alfalfa meal, applied in the field of harvesting and processing technology for producing edible alfalfa meal, can solve the problems of low nutritional quality and high fiber content, and achieve the effects of rich nutrition, high product quality and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

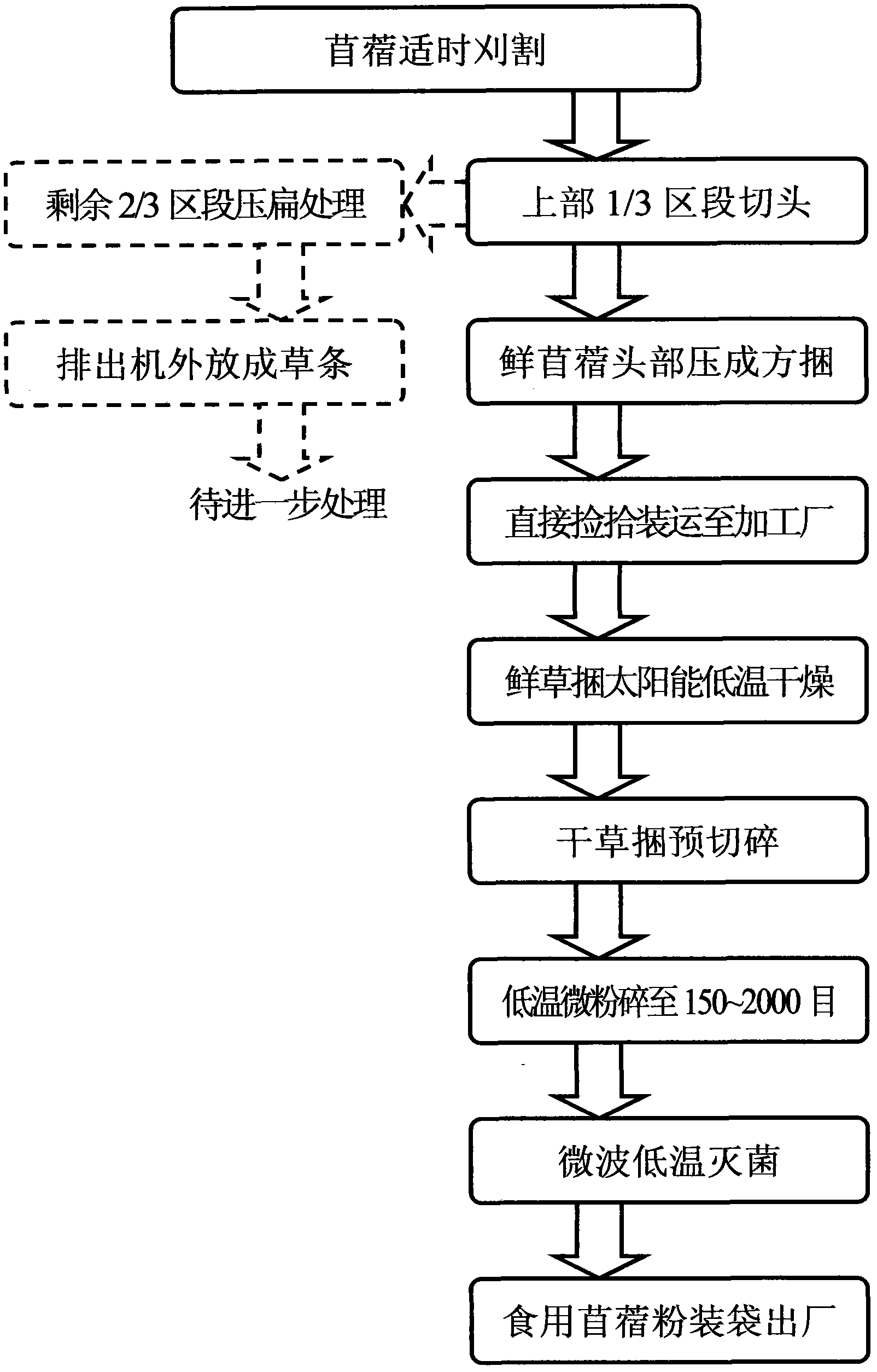

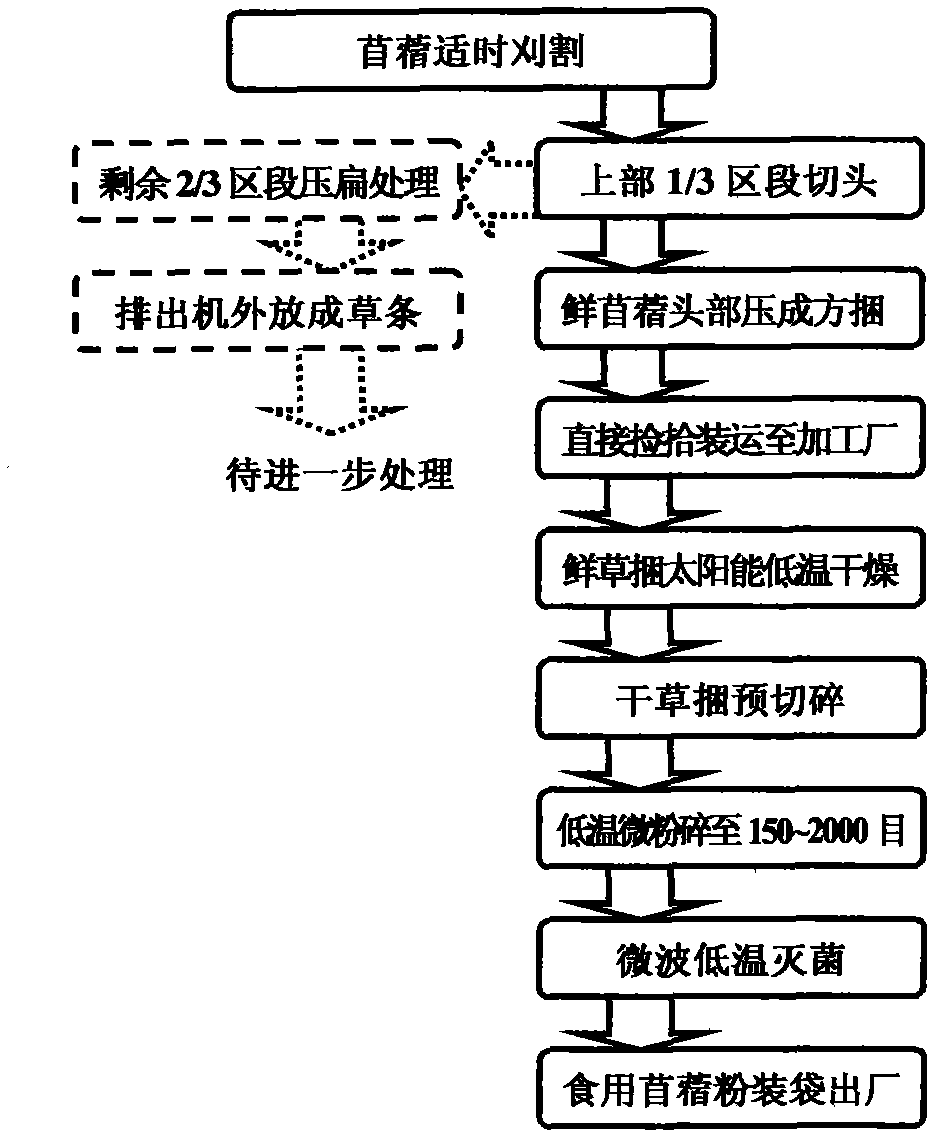

[0013] Harvesting and processing technology for the production of edible alfalfa meal Research on how to solve the shortcomings of the harvesting and processing technology of whole alfalfa cutting, turning, picking and chopping, transportation and high-temperature processing.

[0014] Through the experimental research on the harvesting and processing technology of the whole alfalfa, the data of the nutrients in different sections of the dry matter of the whole alfalfa per 100 grams of the whole plant at the initial flowering stage suitable for harvesting are obtained: the upper 1 / 3 section of the harvested fresh alfalfa plant The dry matter contains 31% protein, 1.1% crude fat, and 11% crude fiber, while the lower 2 / 3 segment contains 19% protein, 0.96% crude fat, and 23% crude fiber. It can be seen that the side stems, young leaves and flowers in the upper 1 / 3 section are high in nutrients, low in fiber content, and rich in vitamins and carotene; while the plants in the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com