Black tea fungus jelly and preparation method thereof

A technology for kombucha and jelly, which is applied in the field of nutritional food, can solve the problems of easy inactivation of heat-sensitive beneficial components, unsatisfactory flavor and taste, long fermentation time of kombucha, etc., so as to clean up the stomach, improve product quality and nutritional value, and achieve natural color and luster. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

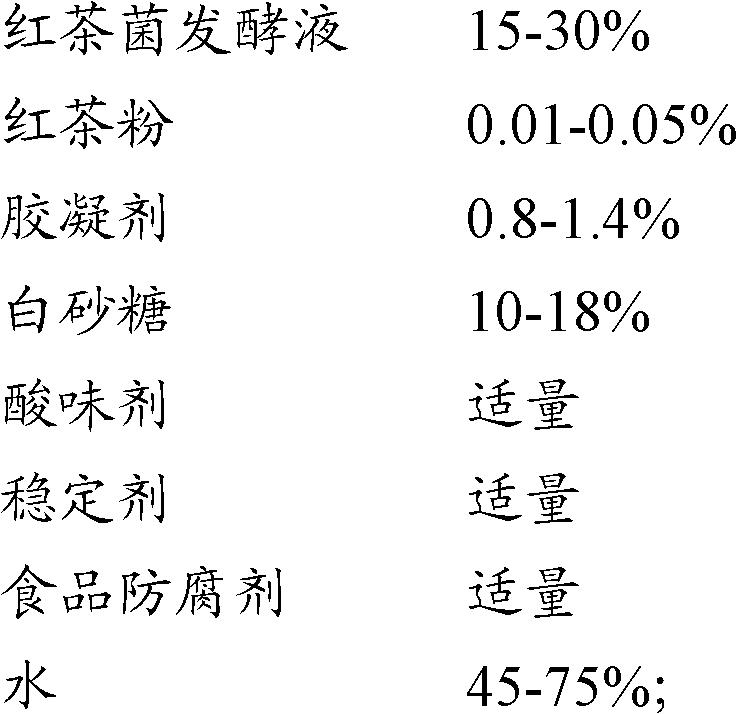

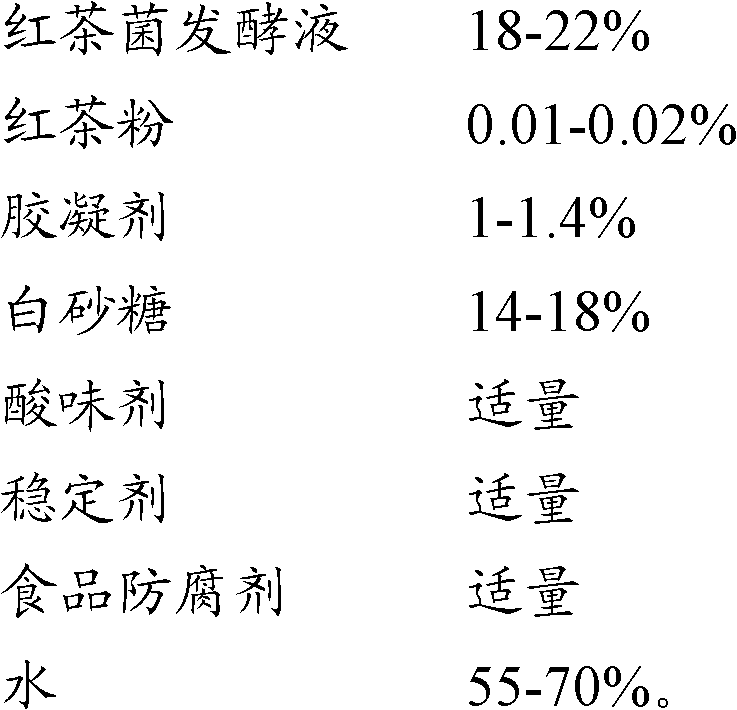

Method used

Image

Examples

Embodiment 1

[0035] In terms of weight percentage, it is prepared from the following raw materials: 20% of kombucha fermented liquid, 0.015% of black tea powder, 1% of compound gelling agent, 16% of white sugar, 0.1% of citric acid, 0.1% of sodium citrate, and potassium sorbate 0.3‰, the balance is water. Wherein, the particle size of black tea powder is 60 mesh; the mass ratio of carrageenan, konjac gum and sodium carboxymethyl cellulose in the composite gelling agent is 2:2:1.

[0036] The preparation method comprises the following steps:

[0037] (1) Preparation of kombucha fermented liquid: weigh 5g white granulated sugar, 0.2g black tea, 0.1g (NH 4 ) 2 SO 4 and 0.1gKH 2 PO 4 ; Boil 100mL distilled water to boiling, add black tea leaves when cooled to 90°C, keep warm at 85°C for 10min, filter out tea residue; add white sugar, (NH 4 ) 2 SO 4 and KH 2 PO 4 , and stir evenly; after bandaging, sterilize under high pressure at 121°C for 20 minutes to prepare a culture medium; afte...

Embodiment 2

[0046] In terms of weight percentage, it is prepared from the following raw materials: 18% of kombucha fermented liquid, 0.02% of black tea powder, 1.2% of compound gelling agent, 18% of white sugar, 0.18% of citric acid, 0.1% of sodium citrate, and potassium sorbate 0.3‰, the balance is water. Wherein, the particle size of black tea powder is 60 mesh; the mass ratio of carrageenan, konjac gum and sodium carboxymethyl cellulose in the composite gelling agent is 10:7:3.

[0047] The preparation method comprises the following steps:

[0048] (1) Preparation of kombucha fermented liquid: weigh 5g white granulated sugar, 0.4g black tea, 0.1g (NH 4 ) 2 SO 4 and 0.1gKH 2 PO 4 ; Boil 100mL of distilled water to boiling, add black tea leaves when cooled to 85°C, keep warm at this temperature for 10min, filter out the tea dregs; add white sugar, (NH 4 ) 2 SO 4 and KH 2 PO 4 , and stir evenly; after bandaging, sterilize under high pressure at 121°C for 20 minutes to prepare a ...

Embodiment 3

[0057] In terms of weight percentage, it is prepared from the following raw materials: 22% of kombucha fermented liquid, 0.01% of black tea powder, 1% of compound gelling agent, 16% of white sugar, 0.18% of citric acid, 0.1% of sodium citrate, and potassium sorbate 0.3‰, the balance is water. Wherein, the particle size of black tea powder is 40 meshes; the mass ratio of carrageenan, konjac gum and sodium carboxymethyl cellulose in the composite gelling agent is 9:9:2.

[0058] The preparation method comprises the following steps:

[0059] (1) Preparation of kombucha fermented liquid: weigh 5g white granulated sugar, 0.3g black tea, 0.1g (NH 4 ) 2 SO 4 and 0.1 g KH 2 PO 4 ; Boil 100mL distilled water to boiling, add black tea leaves when cooled to 90°C, keep warm at 85°C for 10min, filter out tea residue; add white sugar, (NH 4 ) 2 SO 4 and KH 2 PO 4 , and stir evenly; after bandaging, sterilize under high pressure at 121°C for 20 minutes to prepare a culture medium; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com