Method for carrying out anaerobic digestion on kitchen waste after heat-moisture treatment

A technology of moist heat treatment and anaerobic digestion, which is applied in the fields of disposal, harmless solid waste, and resource treatment, and can solve problems such as reducing the effective utilization rate of resources, rapid acidification of materials, and difficulty in collecting, transporting and processing food waste. , to prevent the acidification of materials, improve the oil recovery rate, and ensure the stability of anaerobic digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

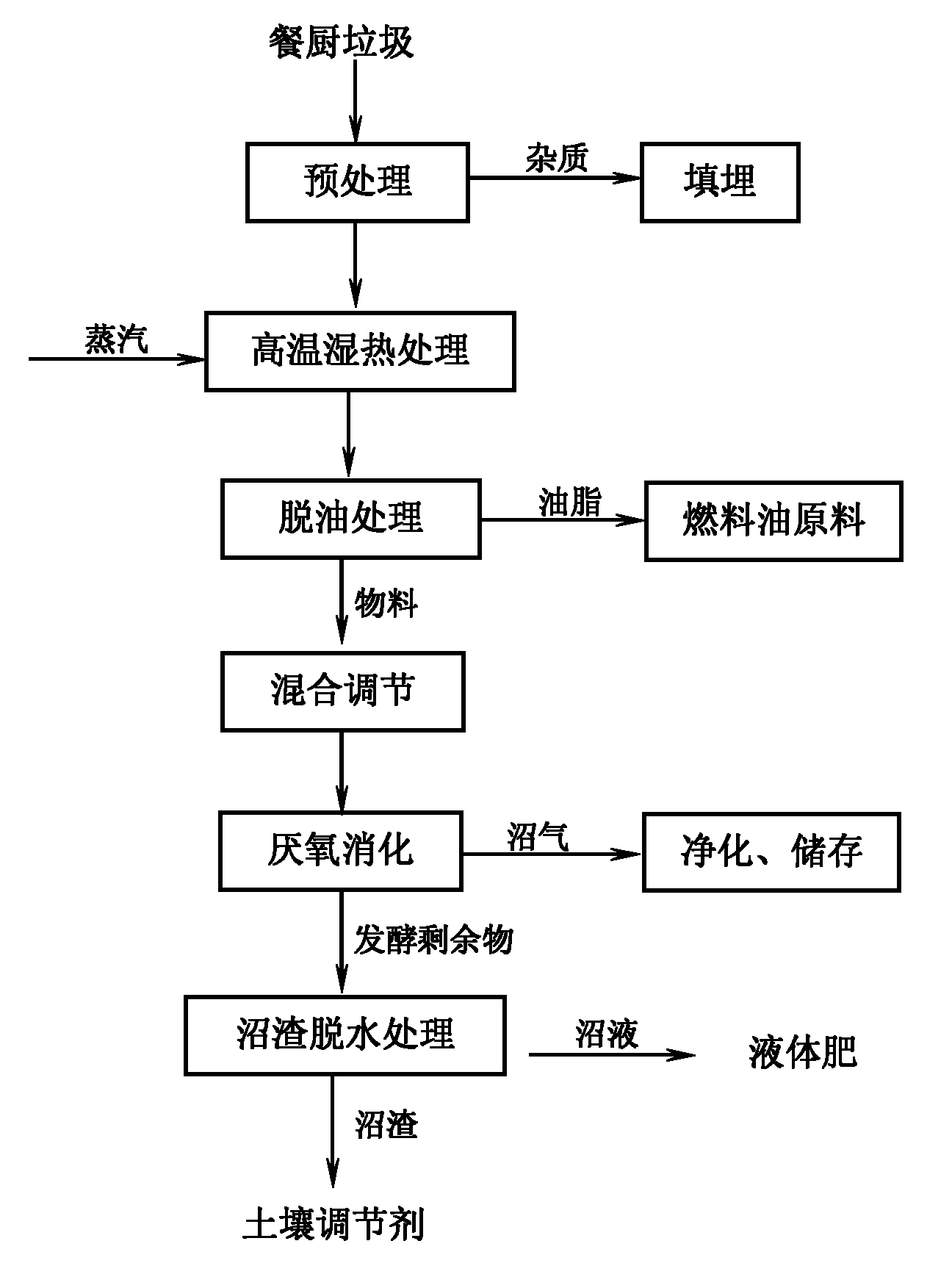

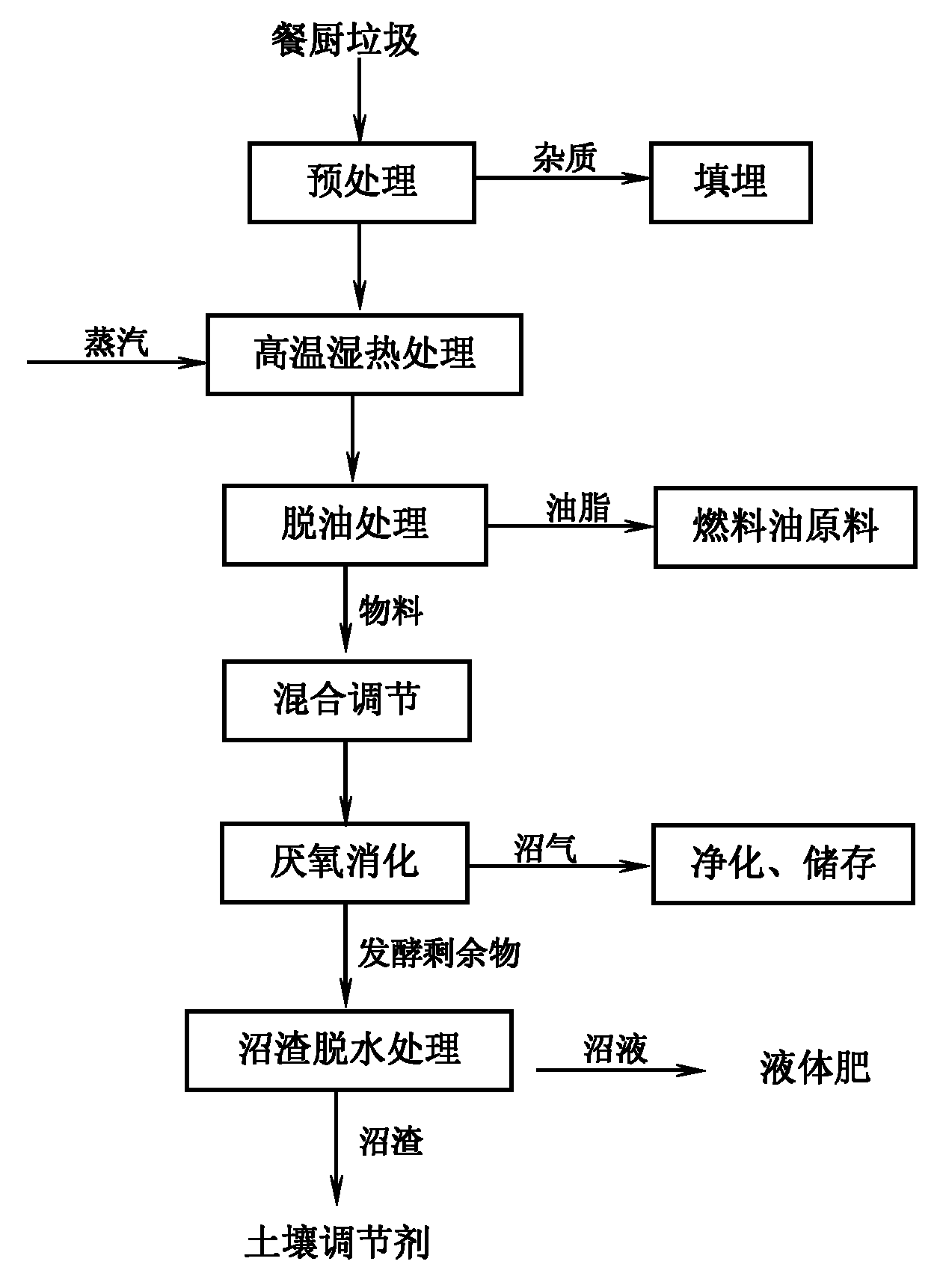

[0029] With reference to the accompanying drawings, the detailed steps of the anaerobic digestion method after the wet heat treatment of the kitchen waste of the present invention are as follows:

[0030] 1. In the pretreatment step, the kitchen waste is transported to the waste disposal point in a professional airtight garbage bin, weighed and then sent to the pretreatment system for crushing, sorting and sedimentation separation pulping steps. The crushing process not only crushes the material to less than 50mm to meet the follow-up process, but also removes metals, stones, glass and other impurities with large specific gravity. In the sorting process, impurities with light specific gravity such as plastic bags are removed by screening to avoid subsequent stirring and entanglement. The sedimentation separation pulping process includes a mixer and a crushing pump to complete the pulping of the material in a cycle, so that the particle size of the material reaches below 10mm. ...

Embodiment 2

[0039] Embodiment 2: A method for anaerobic digestion of kitchen waste after high temperature and heat treatment, comprising the following steps:

[0040] 1. Unloading:

[0041] The food waste is transported to the unloading workshop of the factory area, and the collected food waste is discharged to the material tank for airtight storage. There is a screw conveyor at the bottom. Drop off a portion and collect in the sink.

[0042] The material is conveyed on the belt conveyor, and the preliminary manual screening is carried out on the belt conveying equipment to remove metals, stones, glass, etc. with a large proportion in the kitchen materials, and then transported to the double-shaft crusher for crushing.

[0043] 2. Pretreatment:

[0044] It includes crushing process, sorting and sedimentation separation pulping steps. In order to ensure that there will be no unorganized discharge of odor and sewage spillage, the entire pretreatment process is completed in a closed state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com