Ozone discharging tube, ozone discharging chamber and vertical type ozone generating device

A discharge chamber and discharge tube technology, applied in ozone preparation and other directions, can solve the problems of reducing discharge efficiency, difficult to discharge, high voltage breakdown of discharge tube, etc., and achieve the effect of improving ozone generation efficiency, prolonging service life and increasing charge storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

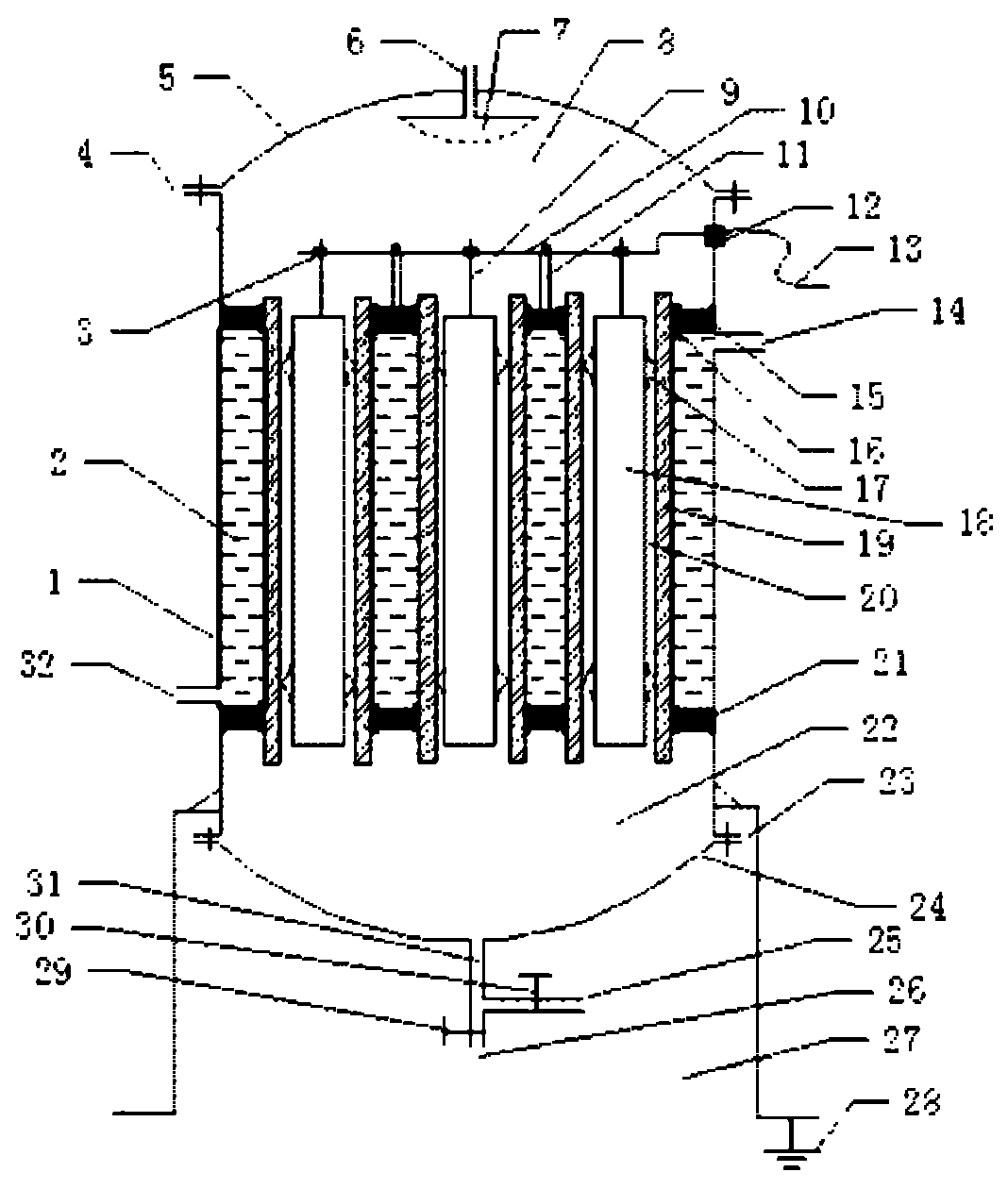

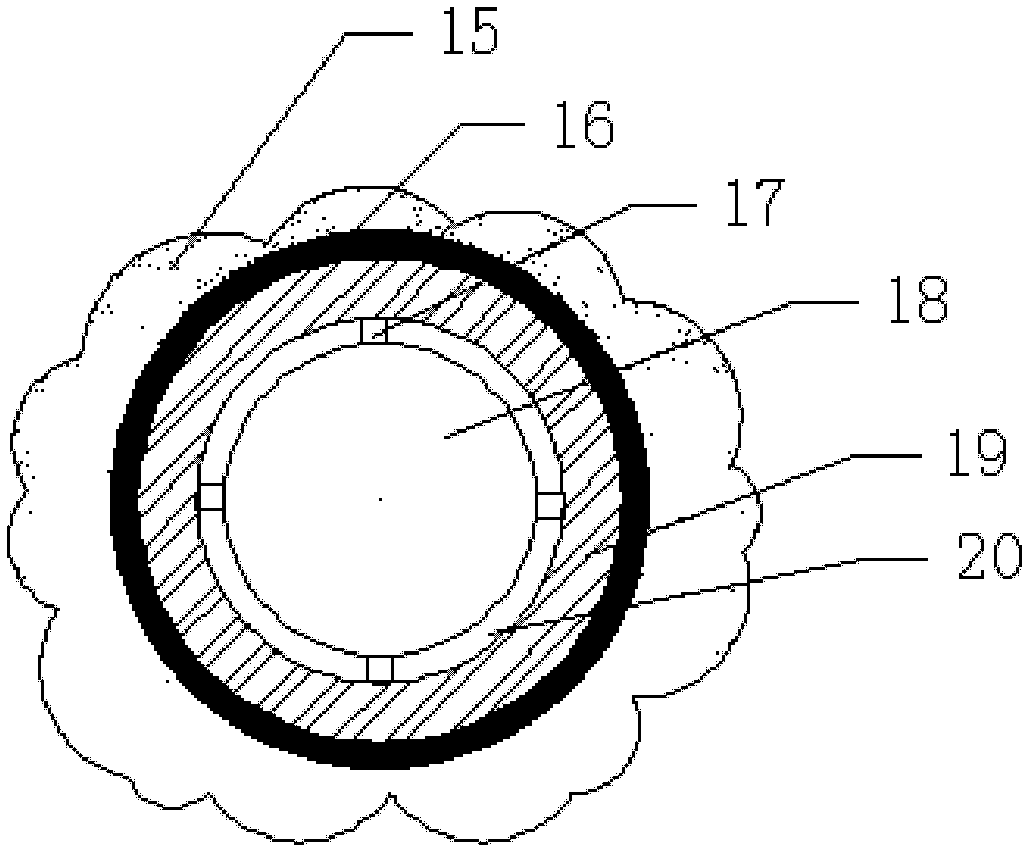

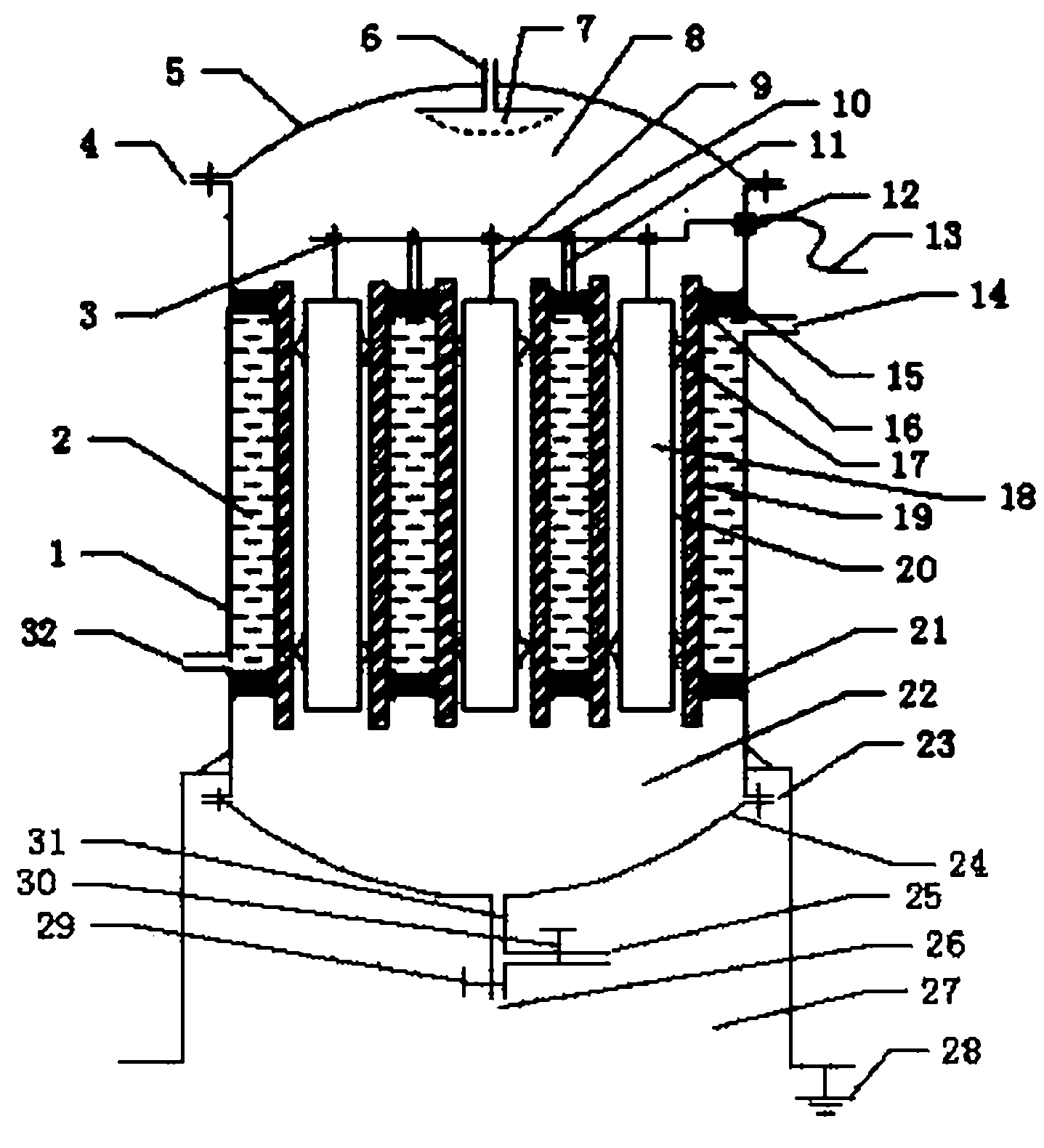

[0027] The technical solutions of the present invention will be further described below in conjunction with the specific embodiments and accompanying drawings.

[0028] like figure 1 , figure 2 Shown, a kind of ozone discharge tube comprises discharge medium tube 19, the high-voltage electrode rod 18 in discharge medium tube 19, and discharge medium tube 19 is titanium quartz glass tube, and the outer wall of titanium quartz glass tube is plated with chromium layer, and discharge medium tube 19 Between the high-voltage electrode rod 18 there is a spring piece 17 to support and form an annular discharge gap 20 (1mm).

[0029] The discharge medium tube is preferably a titanium-quartz glass tube with a diameter of 25mm-30mm, a wall thickness of 2mm-2.5mm, and a length of 1100mm-1300. The titanium-quartz glass tube has a titanium dioxide mass content of 5%-8%, and the outer wall of the titanium-quartz glass tube is electroplated with a layer of chromium. Titanium quartz glass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com