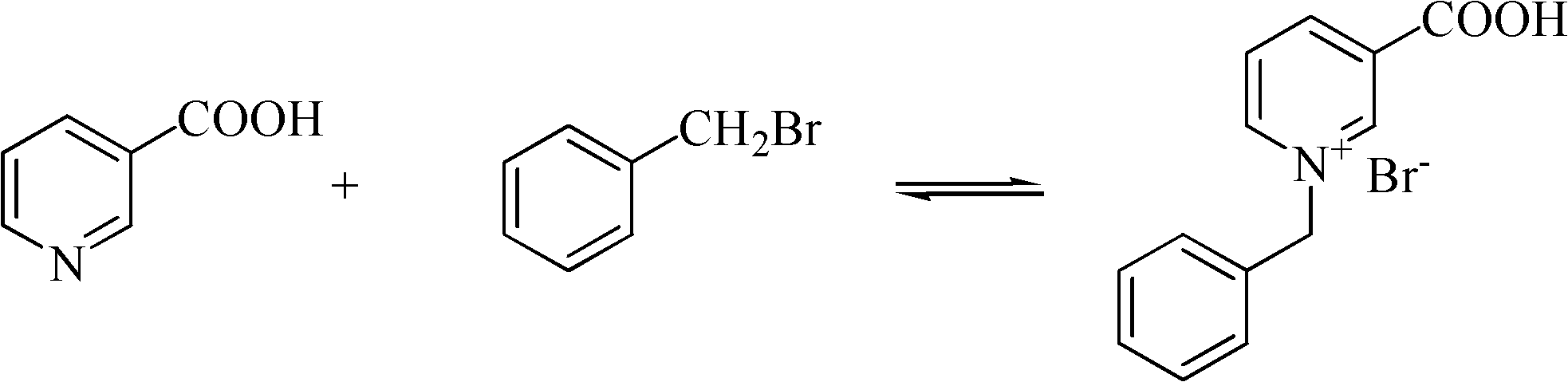

Method for preparing brominated 1-benzyl-3-carboxypyridine and preparation method thereof

A technology of carboxypyridine and benzyl bromide, which is applied in the field of preparation of 1-benzyl-3-carboxypyridine bromide, can solve problems such as environmental pollution, achieve the effects of shortening reaction time, avoiding pollution and energy consumption, and simple purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Niacin (123 grams, 1 mole), benzyl bromide (180 grams, 1.05 moles), and 2500 milliliters of acetonitrile were added in a 5000 milliliter reaction flask equipped with a stirring and reflux device, heated to reflux for reaction, and cooled to room temperature after the reaction. After filtering, the solid was washed twice with 200 ml of acetonitrile. The obtained mother liquor was recovered in a 5000 ml reaction flask, the obtained crude product was added into a beaker containing 1200 ml of distilled water, heated and dissolved, 10 grams of activated carbon was added, heated and boiled for 10 minutes, filtered while hot, the filtrate was cooled to crystallize, filtered, and vacuum-dried , 214.2 g of white crystals—1-benzyl-3-carboxypyridine bromide were obtained, with a yield of 72.8%.

Embodiment 2

[0015] Add nicotinic acid (123 grams, 1 mole), benzyl bromide (205 grams, 1.2 moles), and 2500 milliliters of acetonitrile into a 5000 milliliter reaction flask equipped with a stirring and reflux device, heat to reflux and cool to room temperature after the reaction is complete, filter , the solid was washed twice with 200 ml of acetonitrile. Gained mother liquor is reclaimed in the 5000 milliliter reaction bottle, and gained thick product joins in the beaker that 1200 milliliters of distilled waters are housed, heats to dissolve, adds 10 grams of gacs, heats and boils for 10 minutes, filters while it is hot, filtrate cooling crystallization, filtration, vacuum drying, 228.3 g of white crystals—1-benzyl-3-carboxypyridine bromide were obtained, with a yield of 77.6%.

Embodiment 3

[0017] Add nicotinic acid (123 grams, 1 mole), benzyl bromide (222 grams, 1.3 moles), and 2500 milliliters of acetonitrile into a 5000 milliliter reaction bottle equipped with a stirring and reflux device, heat to reflux for reaction, and cool to room temperature after the reaction is complete , filtered, and the solid was washed twice with 200 ml of acetonitrile. Gained mother liquor is reclaimed in the 5000 milliliter reaction bottle, and gained thick product joins in the beaker that 1200 milliliters of distilled waters are housed, heats and dissolves, adds 10 grams of gacs, heats and boils for 10 minutes, filters while hot, filtrate cooling crystallization, filtration, vacuum drying, 236.5 g of white crystals—1-benzyl-3-carboxypyridine bromide were obtained, with a yield of 80.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com