Technique for extracting and separating salidroside from glossy privet fruit

A technology for crude salidroside and salidroside, which is applied in the field of extraction and separation technology of salidroside in Oleaceae plant Ligustrum lucidum, can solve the problems of low content of crude salidroside and the like, and achieves easy subsequent processing. , the effect of alleviating insufficient resources and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

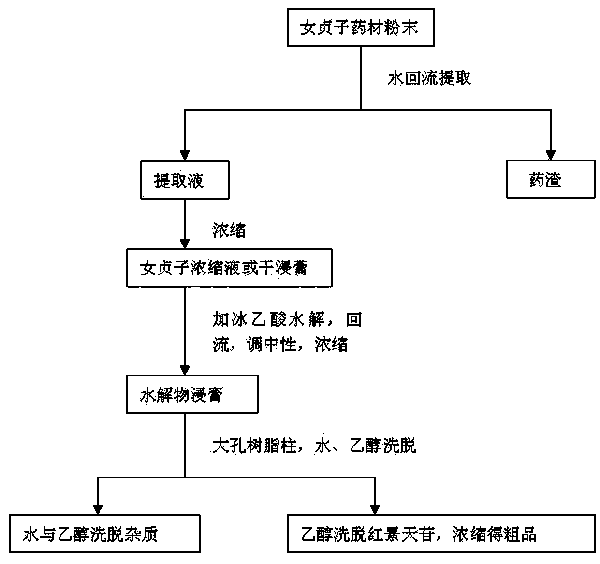

Image

Examples

preparation example Construction

[0041](b) Preparation of reference substance solution: Accurately weigh 1.1 mg of salidroside standard substance to obtain 1.1 mg / mL salidroside standard substance solution; accurately weigh 2.25 mg of tyrosol standard substance to obtain 225 μg / mL tyrosol standard solution. Then accurately draw 0.3 mL and 0.1 mL of the above two standard solutions in turn to make a mixed solution of the two standards, in which the concentration of the standard salidroside is 330 μg / mL, and the concentration of the standard tyrosol is 22.5 μg / mL .

[0042] (c) Preparation of the test solution: Weigh the dry extract of Ligustrum lucidum water extract (or the dry extract after hydrolysis), add 20% methanol to dissolve, set the volume in a 10 mL volumetric flask, and pass through a 0.45 μm micro Pore filter membrane, take the continued filtrate, that is.

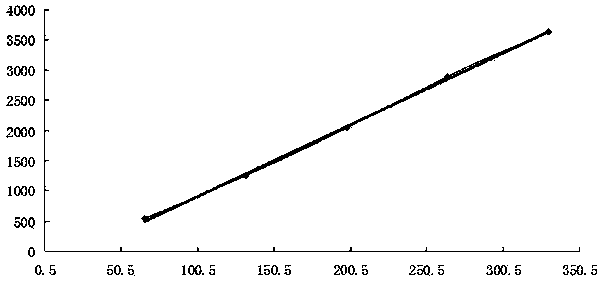

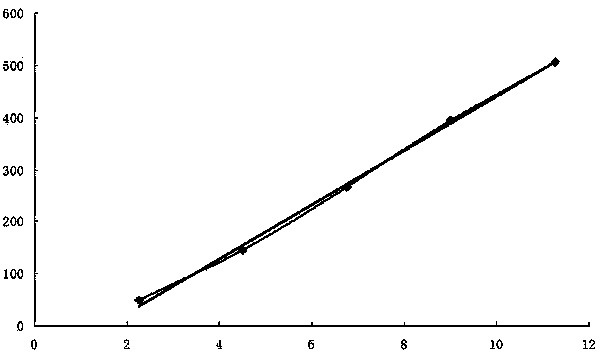

[0043] (d) Determination method: Precisely draw and mix 10 μL of the reference substance solution and 20 μL of the test solution, inject i...

Embodiment 1

[0051] Take the dried and mature fruit of Ligustrum lucidum of the genus Ligustrum in the family Oleaceae, crush it to a coarse powder, add 8 times the amount of water to reflux and extract 3 times, each time is 2 hours, combine the extracts, and recover the solvent under reduced pressure at 80 ° C to obtain dried Extract concentration of 0.05 g / mL is Ligustrum lucidum concentrate, of which the yield of dry extract is 25.1%, and the content of salidroside is 1.65%. The dry extract concentration of 0.05 g / mL means that 1 mL of concentrated solution contains 0.05 g of dry extract, that is, 0.5 mg of dry extract can be obtained by recovering the solvent from 1 mL of concentrated solution to dryness.

[0052] Take 2 mL of the concentrated solution, add 100 μL of glacial acetic acid, that is, glacial acetic acid with a volume ratio of 20:1, and reflux at 100 °C for 20 hours. Adjust to neutral with sodium bicarbonate, recover the solvent under reduced pressure at 80°C to dryness...

Embodiment 2

[0064] Take the dried and mature fruit of Ligustrum lucidum, which is a plant of the genus Ligustrum in the family Oleaceae, crush it into a coarse powder, add 10 times the amount of water to reflux and extract 3 times, each time is 2 hours, combine the extracts, and recover the solvent under reduced pressure at 80 ° C to obtain Ligustrum Chaste seed concentrate.

[0065] Add glacial acetic acid with a volume ratio of 20:1 to the concentrate, and reflux at 100°C for 20 hours. Adjust to neutral with sodium bicarbonate, and recover the solvent to dryness under reduced pressure at 80°C to obtain salidroside hydrolyzate extract. Add a certain volume of distilled water to the hydrolyzate extract, so that the volume ratio of the amount of medicinal material to the dispersed solution is 1:2 (the amount of medicinal material refers to the weight of Ligustrum lucidum g: solution volume mL). Then centrifuge at a speed of 5000 rpm for 40 minutes, pour out the supernatant, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com