Zinc-manganese-titanium alloy for hot dipping

A zinc-manganese-titanium alloy, hot-dip technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of uneven coating thickness, affecting production progress, low coating qualification rate, etc., and achieve reduction Coating thickness, enhanced corrosion resistance and mechanical properties, effect of uniform coating thickness

Inactive Publication Date: 2012-06-13

ZHUZHOU CHUANGLIN ALLOY

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for steel with complex hot-dip components, the hot-dip galvanizing bath is prone to cause more coating quality problems, such as uneven coating thickness, over-thickness, Sandelin effect, color difference, etc., although zinc-aluminum (Zn-Al) Series alloys and zinc-nickel (Zn-Ni) series alloy baths can improve the coating quality to a certain extent, but the hot-dip process of this series of alloy baths is complicated, the cost is high, and the hot-dip time is long, especially for steel materials with complex components. Hot-dip galvanizing in batches, the qualified rate of the coating is low, and it will also affect the production progress

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0013] A zinc-manganese-titanium alloy for hot-dip galvanizing, the weight components of which are Mn 0.5%; Ti 1.5%; the balance is Zn.

Embodiment 2

[0015] A zinc-manganese-titanium alloy for hot-dip galvanizing, the weight components of which are Mn 2.5%; Ti 1.5%; and the balance is Zn.

Embodiment 3

[0017] A zinc-manganese-titanium alloy for hot-dip galvanizing, the weight components of which are Mn: 0.5%; Ti: 0.3%; the balance is Zn.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

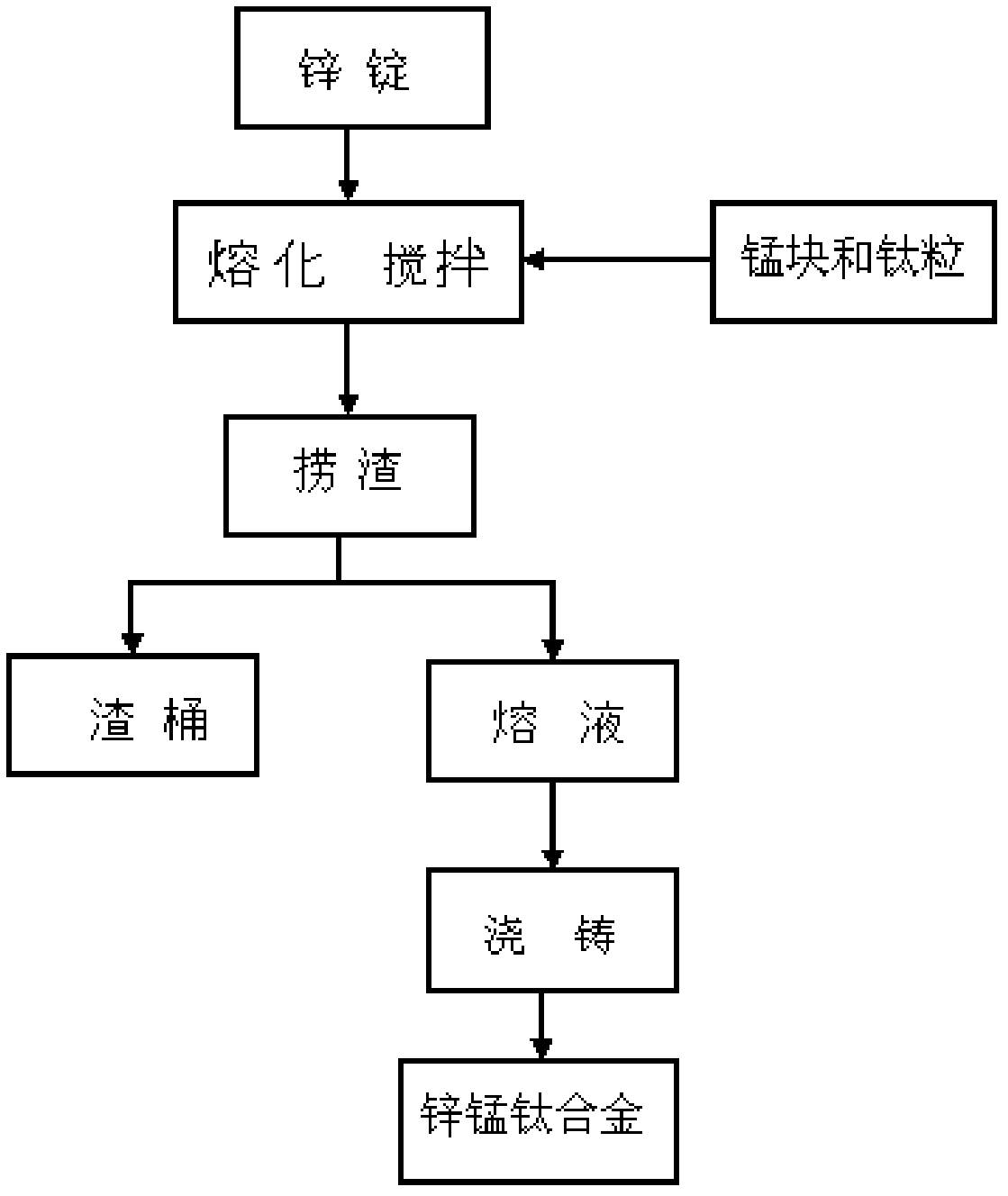

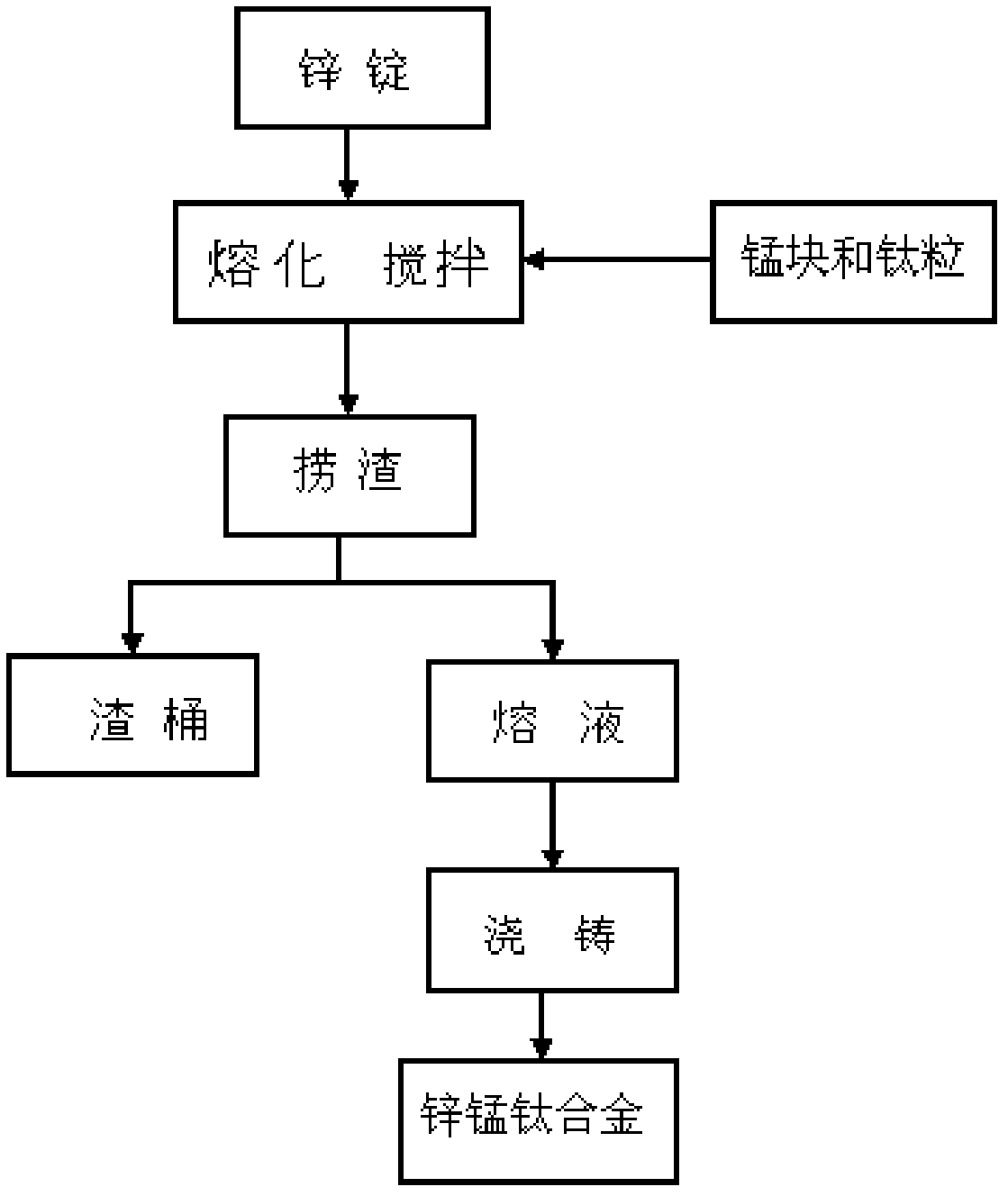

The invention relates to a zinc-manganese-titanium alloy for hot dipping. The zinc-manganese-titanium alloy contains the following components of: by weight, 0.5-2.5% of Mn, 0.3-1.5% of Ti and the balance being Zn. The zinc-manganese-titanium alloy is manufactured by the following steps of: heating for fusing, uniformly stirring, dredging slag, casting molding, and cooling at normal temperature to form the massive zinc-manganese-titanium alloy. The zinc-manganese-titanium alloy provided by the invention requires simple manufacturing technology and low manufacturing cost. With the addition of the zinc-manganese-titanium alloy in a zinc bath, fluidity of zinc alloy bath is good; workpiece surface has advantages of uniform thickness, no color difference, no Sandelin effect and no zinc knot; the coating thickness is reduced; corrosion resistance and mechanical property of the alloy coating are enhanced; hot-dipping time is shortened; production cost is reduced; and coating quality and production efficiency are raised.

Description

technical field [0001] The invention relates to an alloy for hot-dip plating, in particular to a zinc-manganese-titanium alloy for hot-dip plating. Background technique [0002] At present, the zinc baths used in hot-dip galvanizing generally use zinc alloy baths. Zinc alloy bath hot dip galvanized coating with excellent corrosion resistance, good surface quality and excellent bonding properties and mechanical properties. However, for steels with complex hot-dip galvanizing components, the hot-dip galvanizing bath is prone to more coating quality problems, such as uneven coating thickness, super-thickness, Sterling effect, chromatic aberration, etc. Although zinc-aluminum (Zn-Al) Series alloys and zinc-nickel (Zn-Ni) series alloy baths can improve the coating quality to a certain extent, but this series of alloy baths have complex hot-dip process, high cost, and long hot-dip time, especially for steel materials with complex compositions Batch hot-dip galvanizing has a low ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C2/06C22C18/00

Inventor 周林

Owner ZHUZHOU CHUANGLIN ALLOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com