Tunable Cerenkov radiation source

A radiation source, medium technology, applied in electrical components, circuits, thermoelectric devices, etc., can solve the problems of inability to frequency, tuning, etc., to achieve the effect of small size, overcoming wide radiation spectrum, and good radiation directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

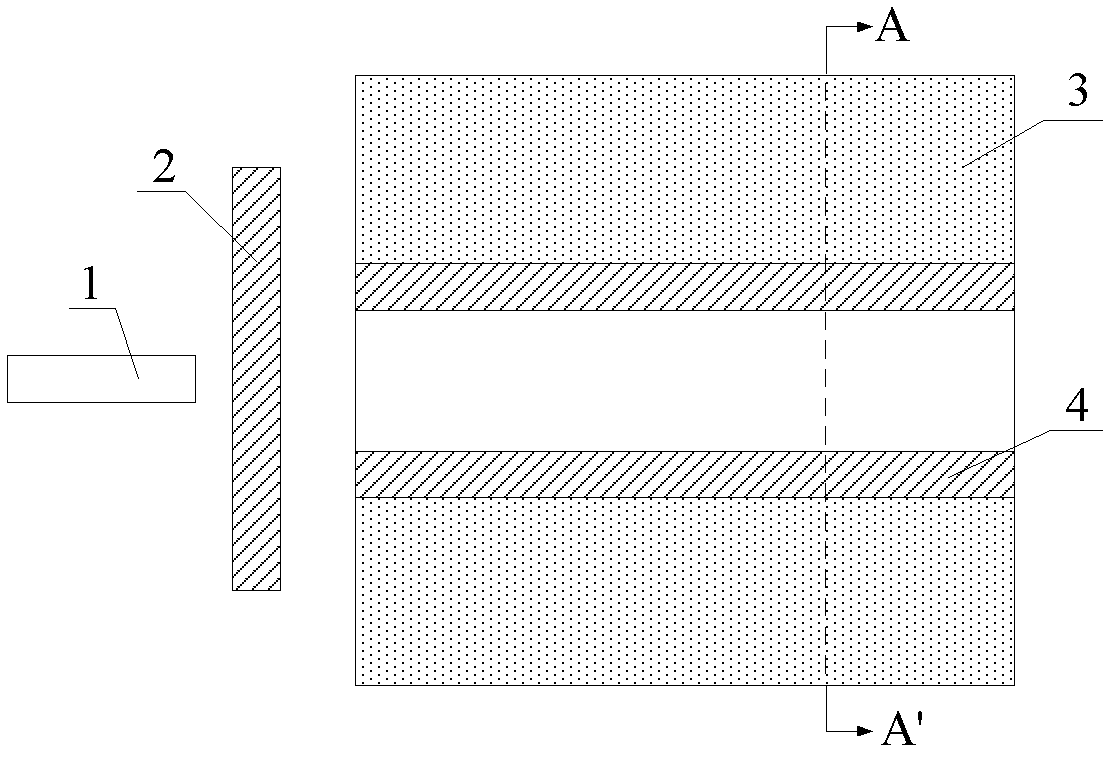

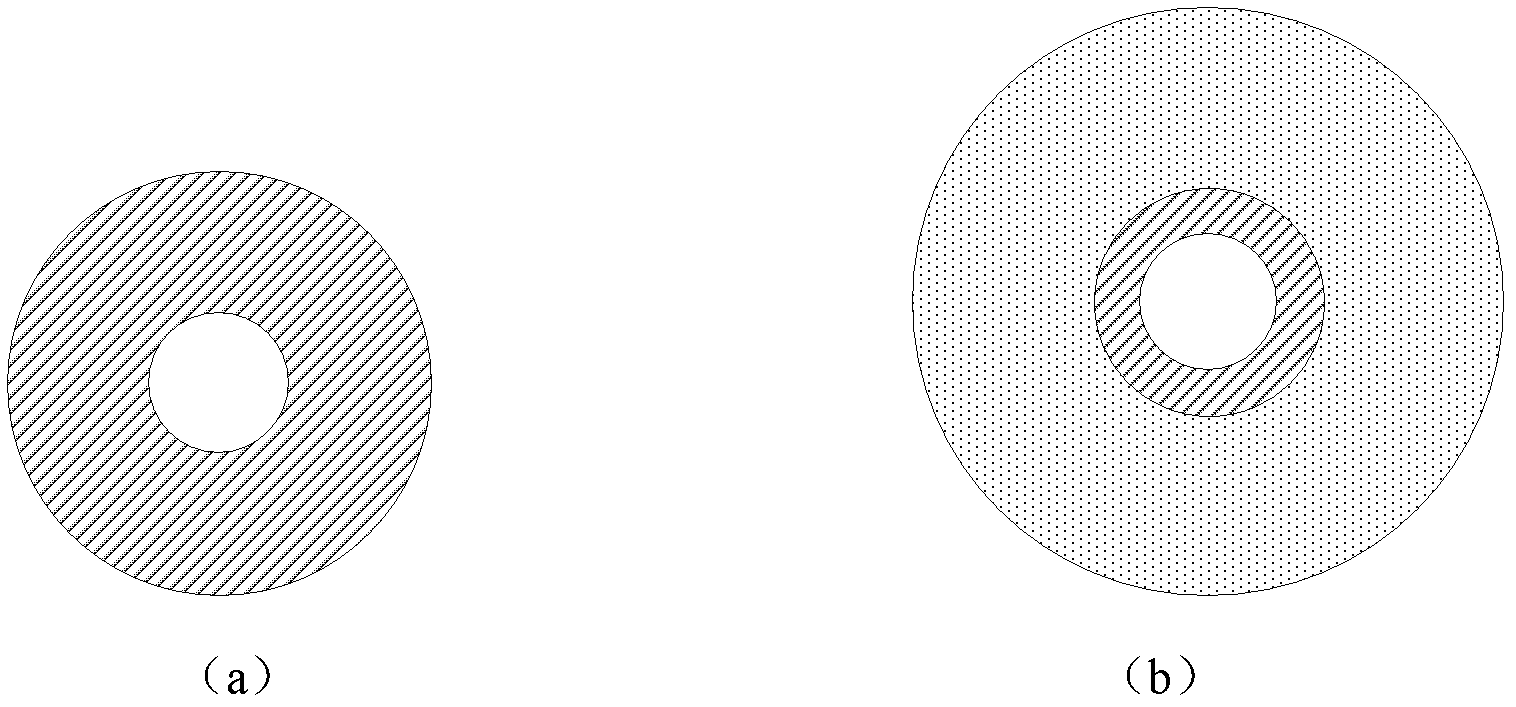

Embodiment 1

[0028] A tunable Cerenkov radiation source includes an electron gun 1, a metal baffle 2, a dielectric torus 3 and a metal thin film layer 4 deposited on the inner surface of the dielectric torus 3. The electron beams emitted by the electron gun 1 pass through the hollow cylinder of the dielectric torus 3 to excite surface plasma waves on the surface of the metal thin film layer 4 . The thickness of the metal thin film layer 4 is less than the skin depth δ of the surface plasmon wave in the metal material used in the metal thin film layer 4 m, so that the surface plasmon waves can pass through the metal thin film layer 4 and reach the medium torus 3 . The ratio β of the moving speed of the electron beam emitted by the electron gun 2 to the speed of light in vacuum and the refractive index n of the material used in the medium torus 3 satisfy the Cerenkov radiation condition: nβ>1, so that the surface plasmon wave can pass through The metallic film layer 4 enters the dielectric ...

Embodiment 2

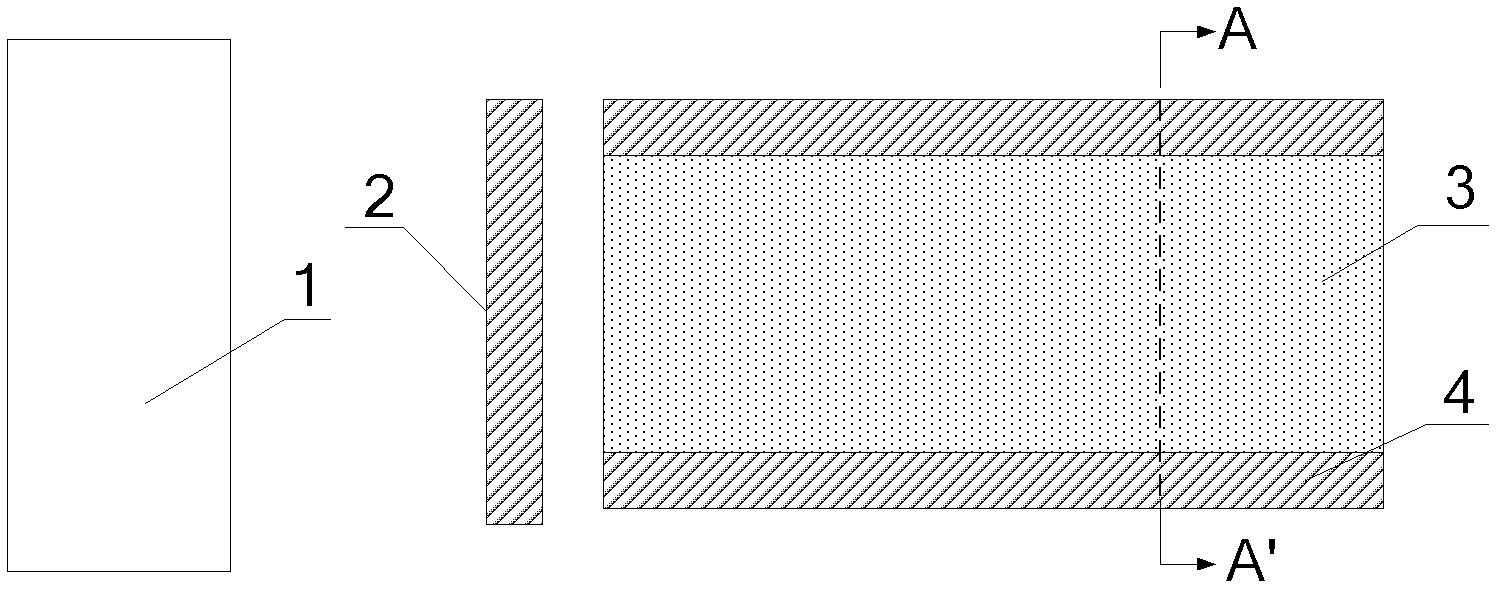

[0032] A tunable Cerenkov radiation source includes an electron gun 1, a metal baffle 2, a dielectric cylinder 3 and a metal thin film layer 4 deposited on the outer surface of the dielectric cylinder 3. The electron beam emitted by the electron gun 1 skims over the outer surface of the metal thin film layer 4 to excite surface plasmon waves on the surface of the metal thin film layer 4 . The thickness of the metal thin film layer 4 is less than the skin depth δ of the surface plasmon wave in the metal material used in the metal thin film layer 4 m , so that the surface plasmon wave can penetrate the metal thin film layer 4 and reach the dielectric cylinder 3 . The ratio β of the moving speed of the electron beam emitted by the electron gun 2 to the speed of light in vacuum and the refractive index n of the material used in the dielectric cylinder 3 satisfy the Cerenkov radiation condition: nβ>1, so that the surface plasma wave can pass through the metal The thin-film layer 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com