Layered lithium-rich anode material clad by metal fluoride, and preparation method thereof

A technology of lithium-rich positive electrode materials and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of large irreversible capacity and poor high rate performance, and achieve improved electrochemical performance, high specific capacity, and good rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Lithium-rich cathode material Li[Li 0.22 Ni 0.17 mn 0.61 ]O 2 Preparation: with the acetate of Li, Ni and Mn as raw material, add excessive oxalic acid (excessive 10%), be mixed with 100 milliliters of metal ion total concentration and be the mixed aqueous solution of 0.5 mole per liter and transfer in the reactor, then Add 10 ml of glacial acetic acid, stir evenly and then seal it; place the reaction kettle in an oven at 120°C for 8 hours and then cool it down naturally, transfer the solution to a beaker and stir until the solvent is completely evaporated; grind the solid product into powder and transfer it to a crucible , baked at 450°C for 2 hours, and after cooling, the material was ground and pressed into tablets; the pressed material was placed in a muffle furnace and sintered at a high temperature of 750°C for 8 hours to obtain Li[Li 0.22 Ni 0.17 mn 0.61 ]O 2 .

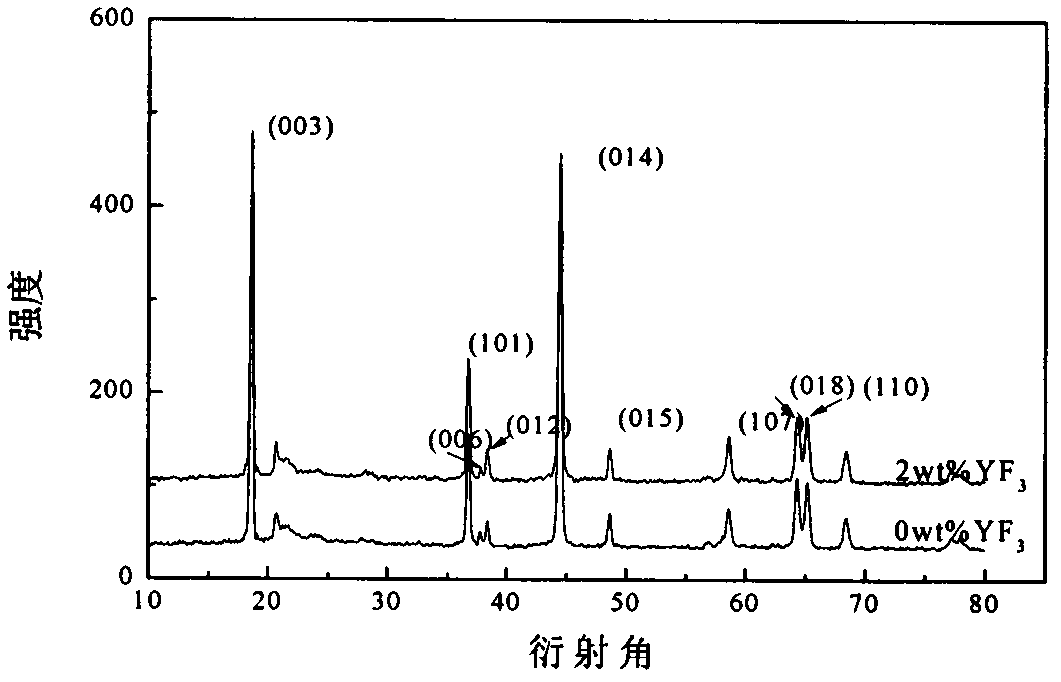

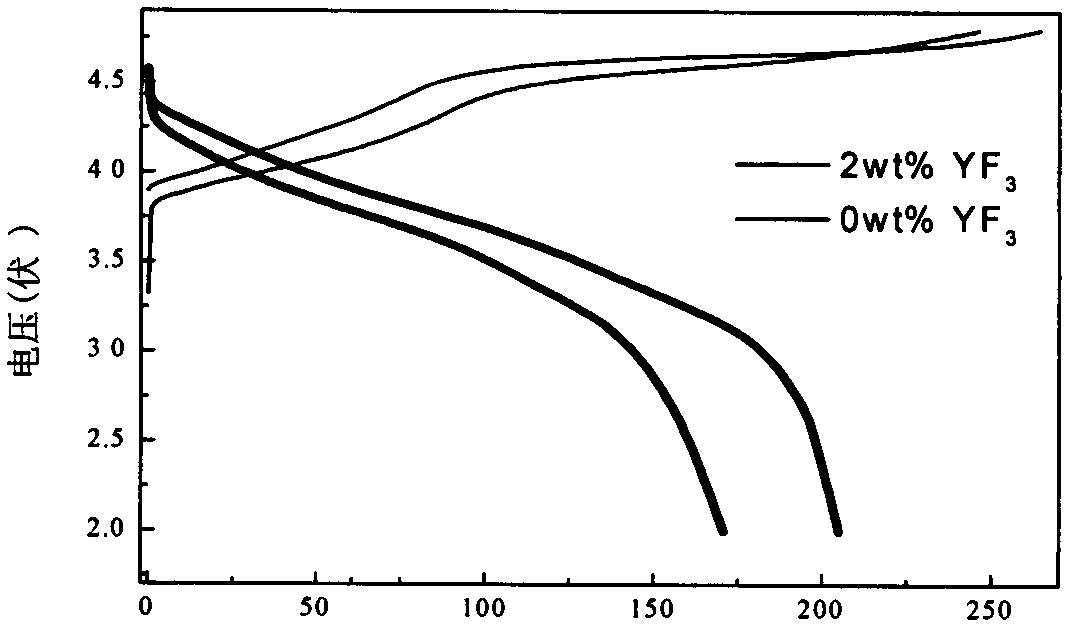

[0024] 2) YF 3 Coated Li[Li 0.22 Ni 0.17 mn 0.61 ]O 2Preparation: Take 5 mmoles of Li[...

Embodiment 2

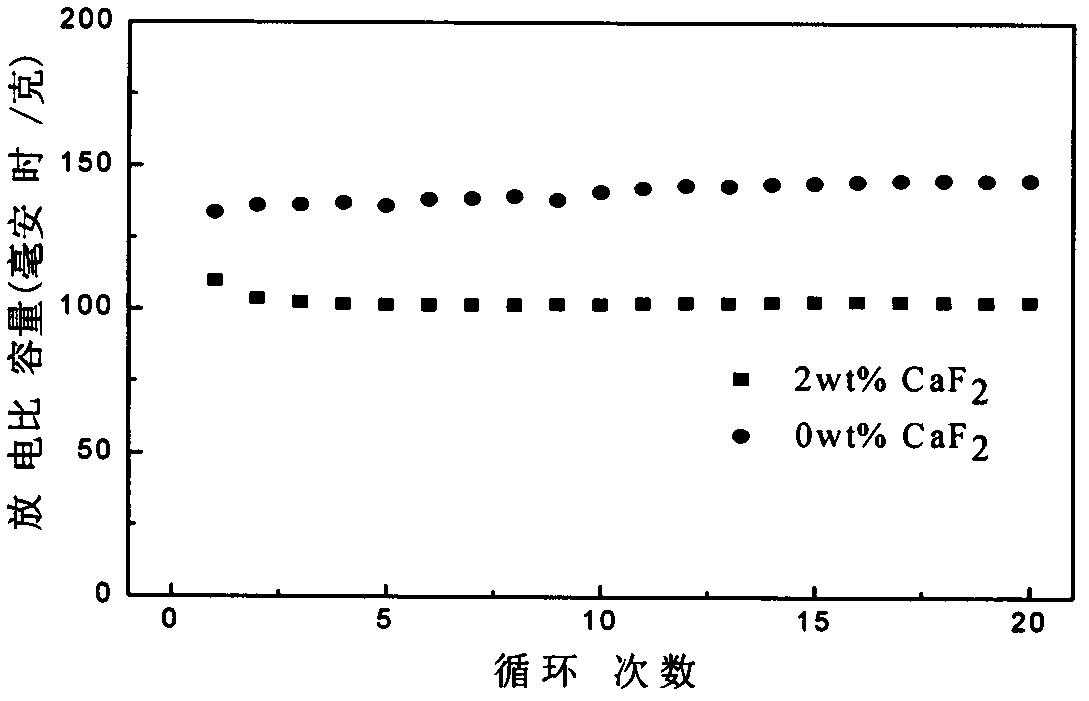

[0028] Change the yttrium nitrate hexahydrate into calcium nitrate tetrahydrate in step 2) in the embodiment 1, the mol ratio of Ca and F is 1: 2, other are the same as embodiment 1. Electrochemical performance tests such as image 3 As shown, at a current density of 300 mA / g, the coated CaF 2 The discharge specific capacity of the final material reaches up to 145 milliampere hours per gram, and the discharge specific capacity is obviously improved, and the cycle performance of the material is also improved.

Embodiment 3

[0030] Change the yttrium nitrate hexahydrate in step 2) in embodiment 1 to lanthanum nitrate hexahydrate, LaF 3 with Li[Li 0.22 Ni 0.17 mn 0.61 ]O 2 Ratio control is 3wt%, other is with embodiment 1. Figure 4 is material coated LaF 3 The discharge cycle curves at different current densities before and after, it can be seen from the figure that the rate performance of the coated material has been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com