Method for providing oxidant with stable flow and purity for oxygen rich combustion supporting of kiln

An oxygen-enriched combustion-supporting, stable flow technology, applied in the direction of energy input, oxygen preparation, etc., can solve the problems of oxygen-enriched air flow rate, oxygen purity change, application constraints of oxygen-enriched combustion-supporting system, etc., and achieve the effect of promoting combustion-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

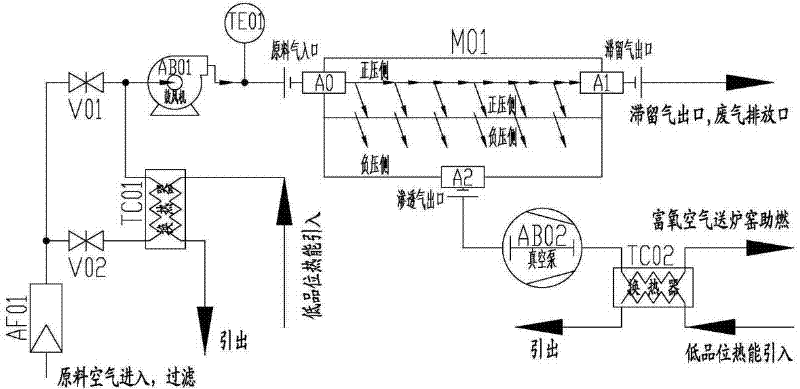

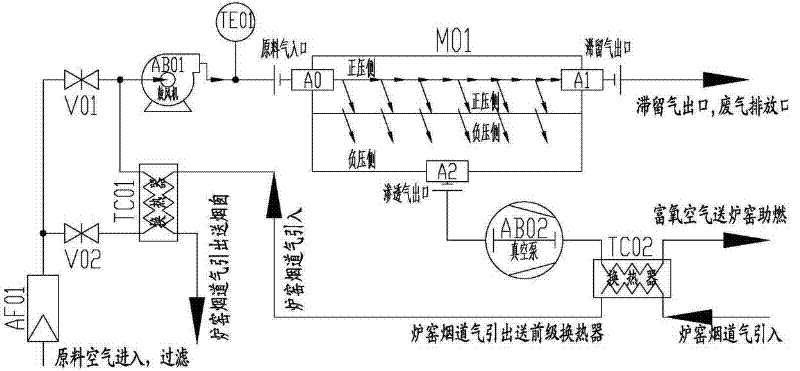

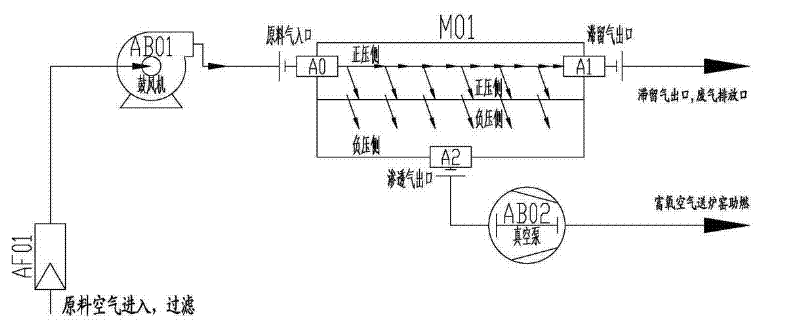

Embodiment 1

[0050] A system that uses Oxylead? plate membrane separator to provide oxidant for cement rotary kiln oxygen-enriched combustion. The designed plate membrane separator is a single-component oxygen-enriched flow rate of 5000Nm3 / hr. Oxylead? plate membrane separator is produced by Shanghai Haoshan Industrial Co., Ltd. , can be obtained from the market, the oxygen and nitrogen separation membrane material used in the separator has a separation coefficient of about 2.05 at 25°C, an oxygen permeation rate of 5.068 Nm3 / hr.bar.m2, and a nitrogen permeation rate of 2.479 Nm3 / hr. bar.m2, 5000Nm3 / hr. The single-component separator uses 1381 m2 membrane material. In this case, a vacuum pump with a pumping speed of 22186 Nm3 / hr at 20°C was selected, and 5256.2 Nm3 of enriched oxygen with a purity of 29.61% was obtained at 25°C. / hr:

[0051] Design ambient temperature 25.0 ℃ Design environment humidity 70.0% Operating altitude 100.0 m operating atmospheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com