Solvothermal preparation method for alkali manganese oxide nanowires

A manganese oxide nano and solvothermal technology, applied in manganese oxide/manganese hydroxide, nanotechnology and other directions, can solve the problems of unfriendly environment and complicated preparation methods, and achieve the effects of single morphology, good dispersion and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

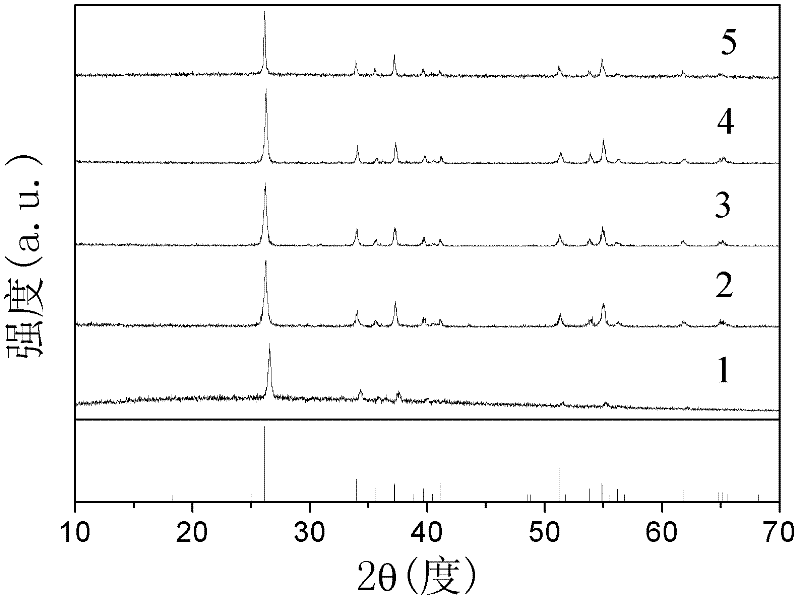

[0019] Mix 2 ml of 0.5 mol / L manganese sulfate solution and 4 ml of 0.5 mol / L potassium permanganate solution, and add to 4 ml of n-butanol aqueous solution with a volume ratio of 1:1, so that manganese sulfate and potassium permanganate After mixing, the molar ratio in the solution is 1:2, stir evenly. The mixed solution was transferred to an autoclave lined with polytetrafluoroethylene, and subjected to solvothermal reaction at a temperature of 140 °C for 6 h to obtain basic manganese oxide nanowires. like figure 1 As shown in the middle curve 1, all the diffraction peaks of the product can correspond to the standard peak of MnO(OH) at the bottom (JCPDS No. 41-1379). According to Scherrer's formula , it can be estimated that the size D in the 022 orientation is 46 nm.

Embodiment 2

[0021] Mix 2 ml of 1.0 mol / L manganese sulfate solution and 4 ml of 1.0 mol / L potassium permanganate solution, and add to 4 ml of n-butanol aqueous solution with a volume ratio of 1:1, so that manganese sulfate and potassium permanganate After mixing, the molar ratio in the solution is 1:2, stir evenly. The mixed solution was transferred to an autoclave lined with polytetrafluoroethylene, and subjected to solvothermal reaction at a temperature of 220 °C for 6 h to obtain basic manganese oxide nanowires. like figure 1 As shown in the middle curve 2, all the diffraction peaks of the product can correspond to the standard peak of MnO(OH) at the bottom (JCPDS No. 41-1379). According to Scherrer's formula , it can be estimated that the size D in the 022 orientation is about 54 nm.

Embodiment 3

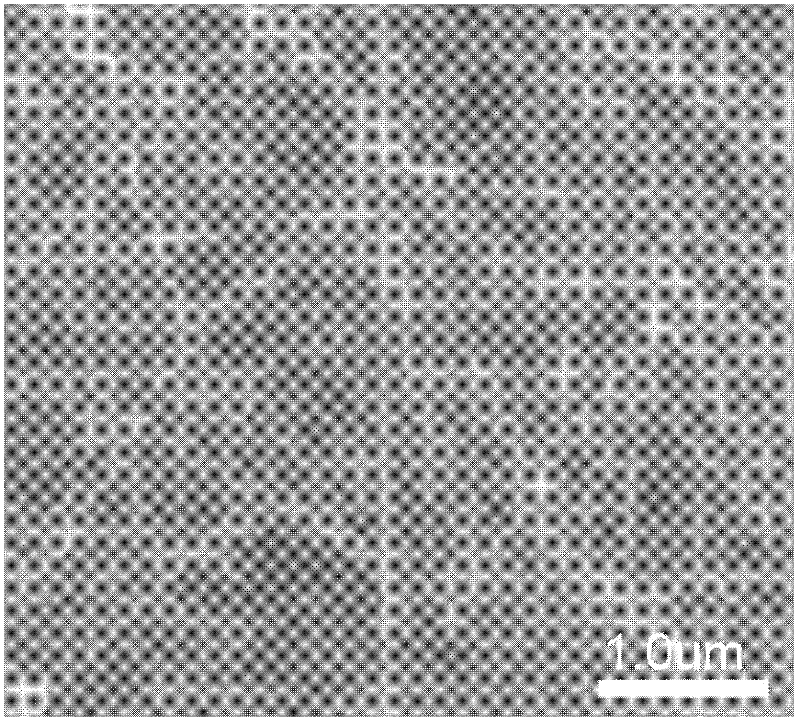

[0023] Mix 4 ml of 1.0 mol / L manganese sulfate solution and 2 ml of 1.0 mol / L potassium permanganate solution, and add to 4 ml of n-butanol aqueous solution with a volume ratio of 1:1, so that manganese sulfate and potassium permanganate After mixing, the molar ratio in the solution is 2:1, stir evenly. The mixed solution was transferred to an autoclave lined with polytetrafluoroethylene, and subjected to solvothermal reaction at a temperature of 160 °C for 24 h to obtain basic manganese oxide nanowires. like figure 1 As shown in the middle curve 3, all the diffraction peaks of the product can correspond to the standard peak of MnO(OH) at the bottom (JCPDS No. 41-1379). According to Scherrer's formula , it can be estimated that the size D in the 022 orientation is about 48 nm. The morphology of the samples was observed using a JEOL 2010 high-resolution transmission electron microscope scanner (accelerating voltage 200 kV), as shown in figure 2 shown. from figure 2 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com