Method for synthesizing three-dimensional porous ferric oxide nano rod cluster

A nano-, three-dimensional porous technology of iron oxide, applied in iron oxide, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of poor repeatability and difficulty in controlling the shape of nanoparticles, and achieve low cost, easy operation, and high technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

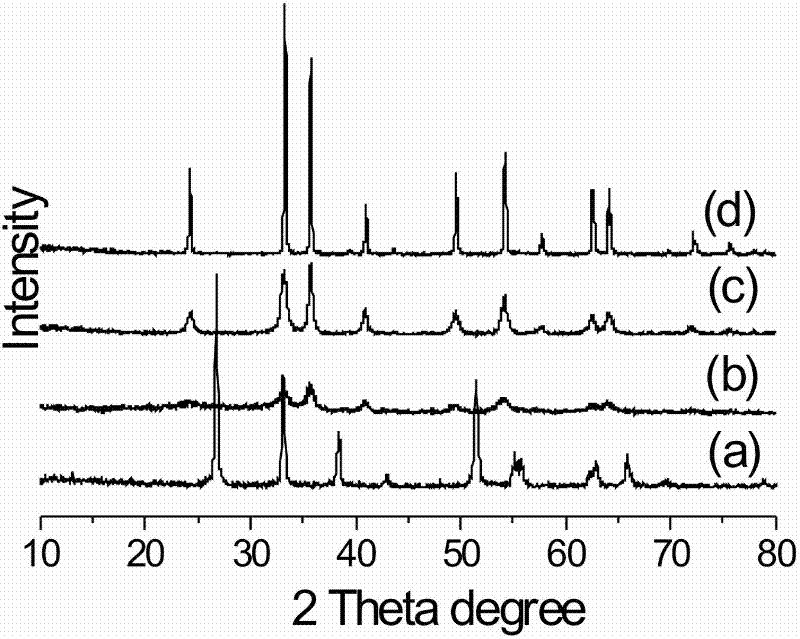

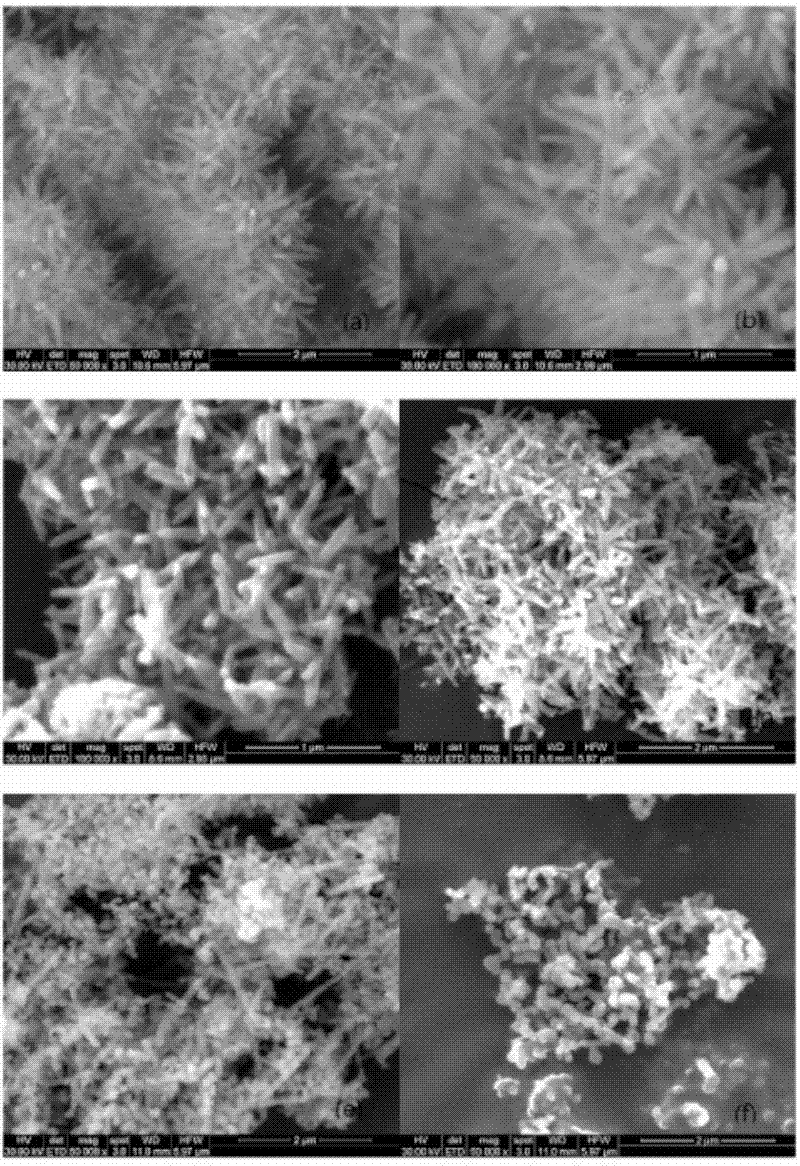

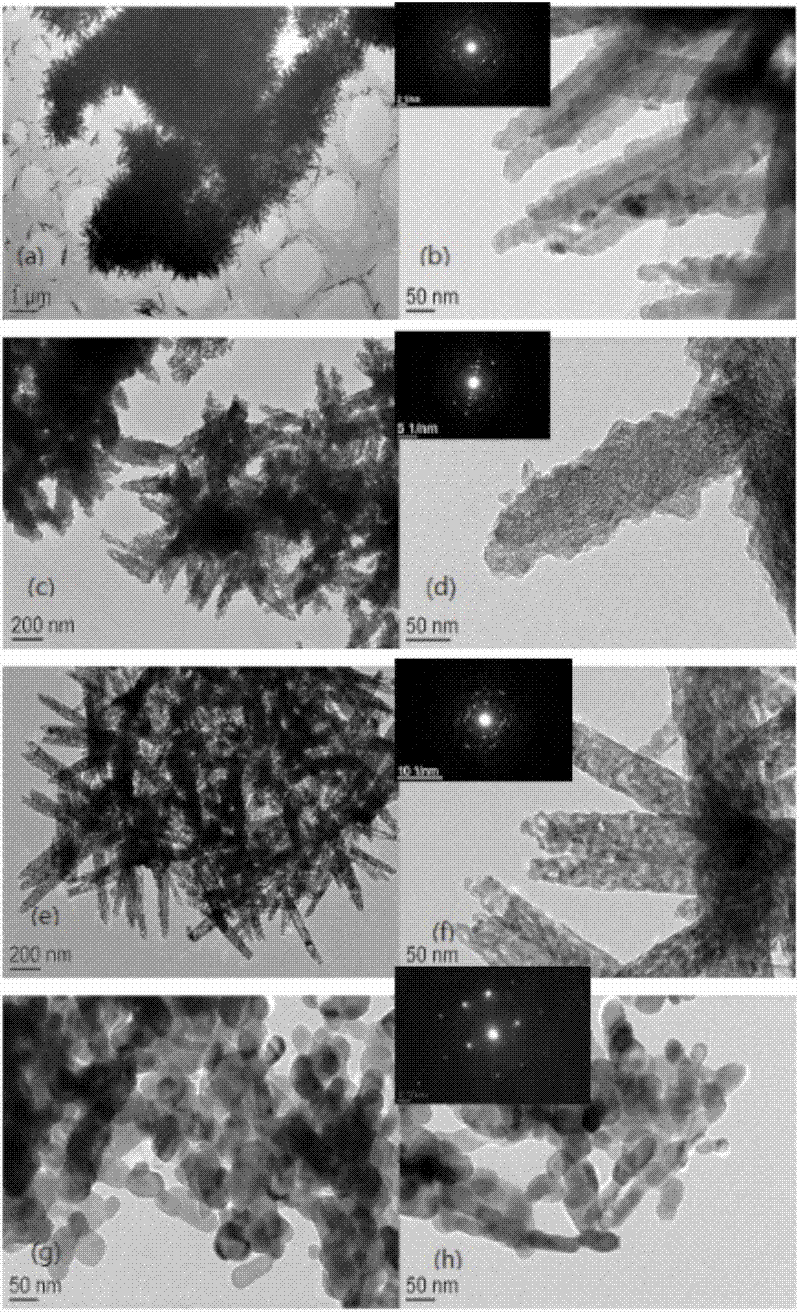

Embodiment 1

[0022] (1) Mix 30g diphenyl ether, 20g [omim][BF 4 ] Add 1g iron acetylacetonate to the autoclave, stir evenly, and charge N 2 Exhaust air, and finally keep N in the reactor 2 The pressure is 2kPa, the stirring speed is controlled at 1000r / min, the temperature is raised to 230°C, and the stirring is carried out for 1h. After the temperature in the reactor drops to room temperature, open the reactor, filter the product and wash with ethanol to obtain FeF 2 .

[0023] (2) The FeF 2 Put it into a ceramic crucible and fire under air atmosphere, the firing temperature is 400℃, and the firing time is 7h. After firing, three-dimensional porous α-Fe can be obtained. 2 O 3 Nanorod clusters.

Embodiment 2

[0025] (1) Mix 25g diphenyl ether, 25g [omim][BF 4 ] Add 1g iron acetylacetonate to the autoclave, stir evenly, and charge N 2 Drain the air, and finally keep N in the reactor 2 The pressure is 2kPa, the stirring speed is controlled at 1000r / min, the temperature is increased to 230°C, and the stirring is performed for 1 hour. After the temperature in the reactor is lowered to room temperature, open the reactor, filter the product and wash it with ethanol to obtain FeF 2 .

[0026] (2) The FeF 2 Put it into a ceramic crucible and fire under air atmosphere, the firing temperature is 400℃, and the firing time is 7h. After firing, three-dimensional porous α-Fe can be obtained. 2 O 3 Nanorod clusters.

Embodiment 3

[0028] (1) Combine 20g diphenyl ether, 30g [omim][BF 4 ] Add 1g iron acetylacetonate into the autoclave together, stir evenly, and charge N 2 Drain the air, and finally keep N in the reactor 2 The pressure is 2kPa, the stirring speed is controlled at 1000r / min, the temperature is raised to 230°C, and the stirring is carried out for 1h. After the temperature in the reactor drops to room temperature, open the reactor, filter the product and wash with ethanol to obtain FeF 2 .

[0029] (2) The FeF 2 Put it into a ceramic crucible and fire under air atmosphere, the firing temperature is 400℃, and the firing time is 7h. After firing, three-dimensional porous α-Fe can be obtained. 2 O 3 Nanorod clusters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com