Special modifying agent for self-compacting concrete of high speed railway ballastless track

A ballastless track and high-speed railway technology is applied in the field of modifiers for self-filling concrete of high-speed railway ballastless tracks, which can solve the problems of self-filling concrete bleeding, laitance and large shrinkage and deformation, and achieves extended operation time, The effect of suppressing bleeding and improving interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The materials of the present invention are obtained by mixing the components according to the following proportions: nano silicon dioxide: 20%, modified metakaolin: 35%, superfine slag powder: 20%, modified starch: 1%, latex powder: 2%, zeolite powder: 10%, polyamide polymer water-absorbing resin: 1%, magnesium oxide expansion agent: 11%.

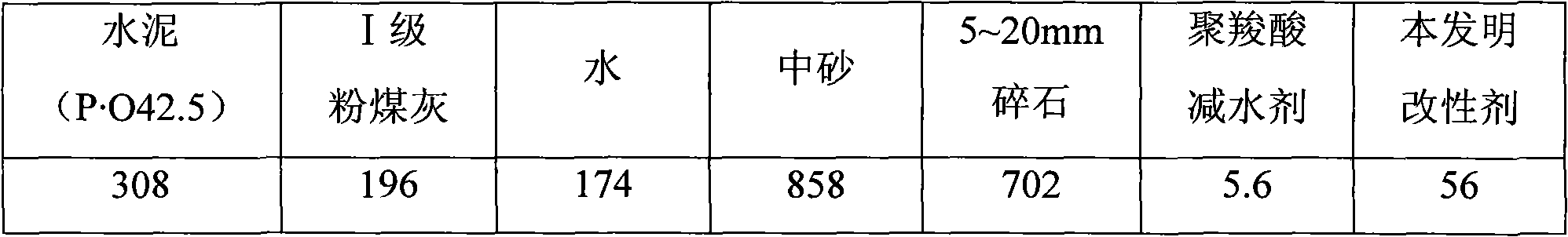

[0019] The prepared self-filling concrete mix proportion of the present invention that adopts above-mentioned prescription to make is shown in Table 1:

[0020] Table 1 Mix ratio of self-filling concrete (kg / m 3 )

[0021]

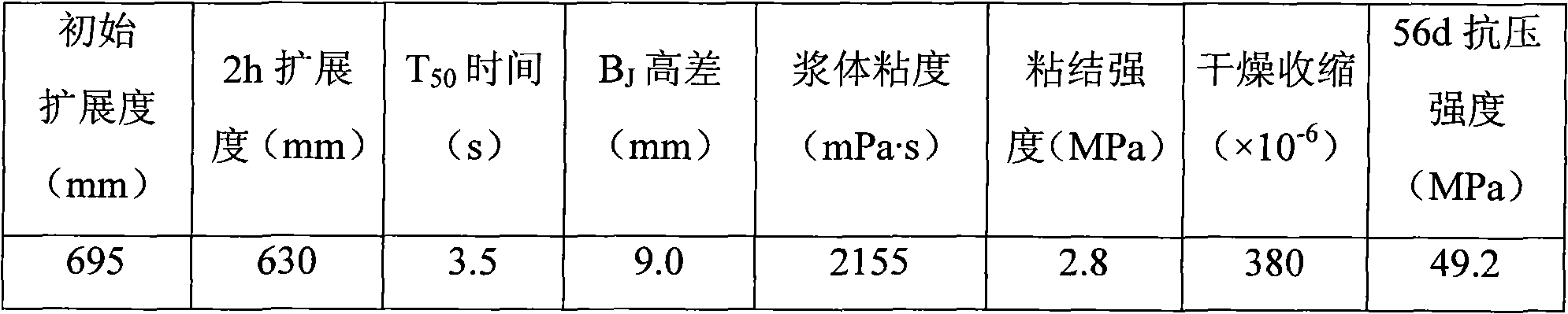

[0022] The prepared self-filling concrete performance of the present invention that adopts above-mentioned prescription to make is shown in Table 2:

[0023] Table 2 Properties of self-filling concrete

[0024]

Embodiment 2

[0026] The material of the present invention is obtained by mixing the components according to the following proportions: nano silicon dioxide: 10%, modified metakaolin: 30%, superfine slag powder: 30%, modified starch: 3.5%, latex powder: 4%, zeolite powder: 10%, starch-based water-absorbing resin: 1%, sodium tripolyphosphate: 0.5%, magnesium oxide expansion agent: 6%, calcium oxide expansion agent: 5%.

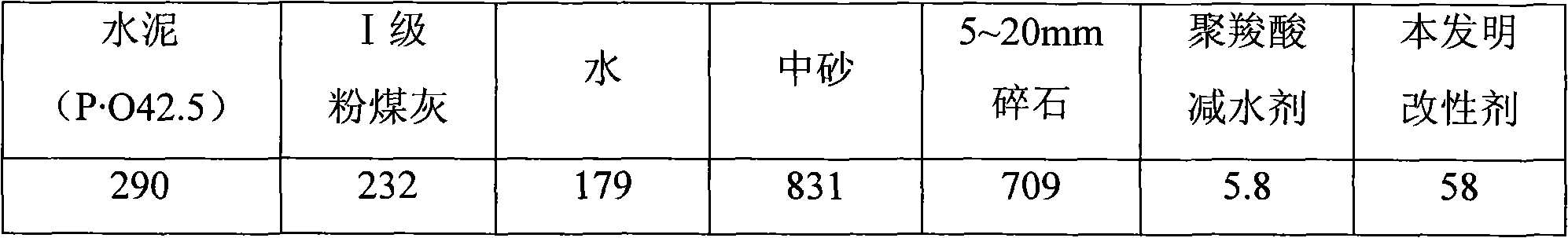

[0027] The prepared self-filling concrete mix proportion of the present invention that adopts above-mentioned prescription to make is shown in Table 3:

[0028] Table 3 Mix ratio of self-filling concrete (kg / m 3 )

[0029]

[0030] The prepared self-filling concrete performance of the present invention that adopts above-mentioned prescription to make is shown in Table 4:

[0031] Table 4 Properties of self-filling concrete

[0032]

Embodiment 3

[0034] The material of the present invention is obtained by mixing the components according to the following proportions: nano silicon dioxide: 15%, modified metakaolin: 27%, superfine slag powder: 20%, modified starch: 3.5%, latex powder: 4%, zeolite powder: 12%, polyamide polymer water-absorbent resin: 1.5%, sodium gluconate: 1.0%, magnesium oxide expansion agent: 10%, calcium oxide expansion agent: 6%.

[0035] The self-filling concrete mix ratio prepared by the present invention that adopts above-mentioned formula to make is shown in Table 5:

[0036] Table 5 Mixing ratio of self-filling concrete (kg / m 3 )

[0037]

[0038] The prepared self-filling concrete performance of the present invention that adopts above-mentioned prescription to make is shown in Table 6:

[0039] Table 6 Performance of self-filling concrete

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com