Process for recycling white mud generated by pulping and papermaking

A technology of pulping, papermaking and white mud, applied in the field of recycling technology of white mud, which can solve the problems of occupying green ecological land resources, reducing the practical value of products, reducing economic benefits, etc., to solve the problem of white mud, and has strong implementability , great social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

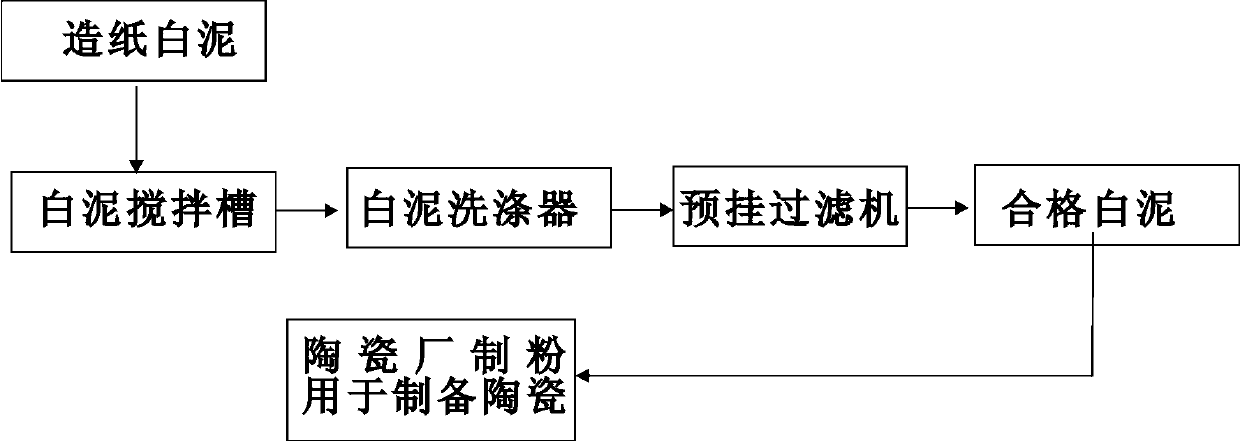

[0019] (1) Dilution and stirring: Pulping and papermaking enterprises extract the lime mud through the pre-hanging filter, enter the lime mud mixing tank, add water to dilute to a residual liquid concentration of 0.8%, and then enter the lime mud scrubber for precipitation;

[0020] (2) Re-washing of the pre-hanging filter: put the above-mentioned precipitated white mud into the pre-hanging filter for washing again, so as to ensure that the residual alkali concentration of the white mud reaches 0.8% and the dryness is 55%;

[0021] (3) Qualified lime mud delivery: transport the qualified lime mud with a residual alkali of 0.8% and a dryness of 55% to various ceramic factories by special transport vehicles;

[0022] (4) Flour making in ceramic factory: Qualified lime mud enters the ceramic factory and is further ground to make powder. The powder replaces the auxiliary material calcite (CaCO 3 ) for the preparation of ceramics; said finished product is of the same quality as the...

Embodiment approach 2

[0024] (1) Dilution and stirring: Pulping and papermaking enterprises extract the lime mud through the pre-hanging filter, enter the lime mud mixing tank, add water to dilute to a residual liquid concentration of 0.7%, and then enter the lime mud scrubber for precipitation;

[0025] (2) Re-washing of the pre-hanging filter: put the above-mentioned precipitated white mud into the pre-hanging filter for washing again, so as to ensure that the residual alkali concentration of the white mud reaches 0.7% and the dryness is 57%;

[0026] (3) Qualified lime mud delivery: transport the qualified lime mud with a residual alkali concentration of 0.7% and a dryness of 57% to various ceramic factories by special transport vehicles;

[0027] (4) Flour making in ceramic factory: Qualified lime mud enters the ceramic factory and is further ground to make powder. The powder replaces the auxiliary material calcite (CaCO 3 ) for the preparation of ceramics; said finished product is of the same ...

Embodiment approach 3

[0029] (1) Dilution and stirring: Pulping and papermaking enterprises extract the lime mud through the pre-hanging filter, enter the lime mud mixing tank, add water to dilute to a residual liquid concentration of 0.6%, and then enter the lime mud scrubber for precipitation;

[0030] (2) Re-washing of the pre-hanging filter: the above-mentioned precipitated white mud is put into the pre-hanging filter for washing again, so as to ensure that the residual alkali concentration of the white mud reaches 0.6% and the dryness is 58%;

[0031] (3) Qualified lime mud delivery: transport the qualified lime mud with a residual alkali concentration of 0.6% and a dryness of 58% to various ceramic factories by special transport vehicles;

[0032] (4) Flour making in ceramic factory: Qualified lime mud enters the ceramic factory and is further ground to make powder. The powder replaces the auxiliary material calcite (CaCO 3 ) for the preparation of ceramics; said finished product is of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com