Dedicated organic/inorganic compound fertilizer for kiwi and preparation method thereof

A technology of kiwi fruit and compound fertilizer, which is applied to the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts. It can solve the problems of volatilization loss, unfavorable yield, and single nutrient, so as to increase yield, improve product quality, and improve utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

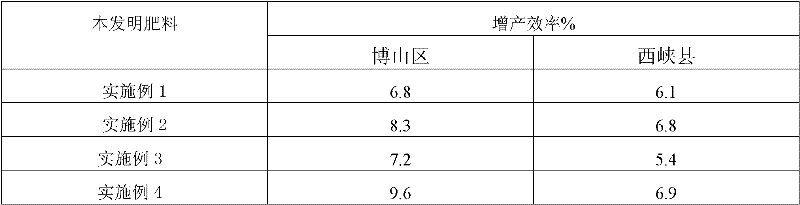

Examples

preparation example Construction

[0019] (1) Preparation of quick-acting nutrient fertilizer: take urea, diammonium phosphate and potassium sulfate according to the ratio and mix them, and then granulate according to the prior art, with a particle size of 2 to 4 mm.

[0020] (2) Preparation of slow-acting nutrient fertilizer: Take urea, potassium sulfate, ferrous sulfate and weathered coal according to the ratio, and mix them well. Spray water to make the moisture content of the mixture reach 18-25wt%, and place it for 8-10 hours; turn over the pile, and place it for another 6-8 hours. It is prepared by granulation according to the prior art, and the particle size is 2 to 4 mm.

[0021] (3) Preparation of long-acting nutrient fertilizer: Ginger plants and pumpkin vines were crushed to less than 0.5 cm in length and set aside.

[0022] Take ginger plant, pumpkin vine, soybean oil oil residue, rapeseed oil oil residue, microbial fermentation agent EM composite agent according to the ratio, and mix them evenly. ...

specific Embodiment approach

[0032] The present invention will be further described below in conjunction with the examples, but not limited thereto. The amounts and parts of raw materials in the examples are parts by mass, and all percentages are percentages by mass.

[0033] Soybean oil residue and rapeseed oil residue are produced by Shandong Everbright Sun Moon Co., Ltd.; the microbial fermentation agent is EM composite agent, produced by Jiangxi Tianyi Biotechnology Development Co., Ltd.

Embodiment 1

[0034] Embodiment 1: organic-inorganic compound fertilizer special for kiwifruit, raw material composition is as follows:

[0035] 20 kg of quick-acting nutrient fertilizer; 30 kg of slow-acting nutrient fertilizer; 50 kg of long-acting nutrient fertilizer.

[0036] Preparation:

[0037] (1) Preparation of quick-acting nutrient fertilizer: get 8 kilograms of urea, 10 kilograms of diammonium phosphate, and 2 kilograms of potassium sulfate crushed to 80 mesh sieves, mix them and make them by granulating according to the prior art, with a particle size of 2 to 4 millimeters.

[0038] (2) Preparation of slow-acting nutrient fertilizer: Take 6 kg of urea, 7 kg of potassium sulfate, 2 kg of ferrous sulfate, and 15 kg of weathered coal crushed to pass through an 80-mesh sieve, and mix well. Spray water to make the moisture content of the mixture reach 19wt%, and place it for 8 hours; turn over the pile, and place it for another 8 hours. According to the prior art granulation, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com