Preparation method of sulfonated polyethersulfone for preparing macromolecule separation films

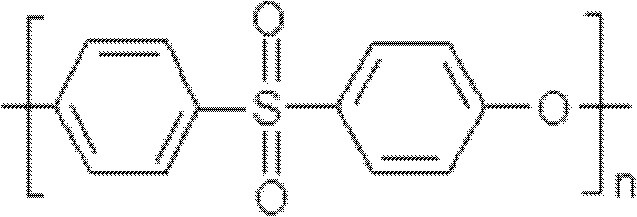

A technology of sulfonated polyethersulfone and separation membrane, which is applied in the field of chemical synthesis of polymer materials, can solve the problems of large space, weakening of large electron cloud, unfavorable complex stability, etc., and achieve stable performance and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The selected reagent of the present invention is: vacuum drying oven, DZF-6050, Shanghai Jinghong; Constant speed agitator, S212-90, Shanghai Shensheng; Ubbelohde viscometer, 1385 flat type; Pure, Lanxi Liudongshan Chemical Industry; 1,2-Dichloromethane (DCM), analytically pure, Chengdu Kelon Chemical; chloroform, analytically pure, Chengdu Kelon Chemical; N,N-Dimethylformamide (DMF) , analytically pure, Chengdu Kelong Chemical; polyethersulfone (PES), 3000P, GAFONE; chlorosulfonic acid, chemically pure, Tingxin Chemical Reagent Factory.

[0027] The polyethersulfone used in the present invention was vacuum-dried at 130° C. for 10 hours.

[0028] Add 10g of polyethersulfone into a three-necked flask filled with 50mL of concentrated sulfuric acid (98%) solvent, stir and dissolve at room temperature to form a homogeneous solution, measure a certain amount of chlorosulfonic acid in a constant pressure dropping funnel, in which the sulfonating agent The molar ratio to poly...

Embodiment 2-4

[0042] According to the method shown in embodiment 1, adopt different solvents to carry out comparative test:

[0043] The influence of solvent on the sulfonation reaction, as shown in the following table

[0044]

[0045]

[0046] The above reaction chlorosulfonic acid addition rate is 3s / d, stirring speed 800r / min.

[0047] It can be seen from the data in the above table that the solvent has an important influence on the sulfonation of polyethersulfone. Among the three solvents selected, 1,2-dichloromethane, chloroform and concentrated sulfuric acid, concentrated sulfuric acid is more suitable as the polyethersulfone solvent. Solvent for sulfonation. According to the reaction mechanism, as the sulfonation reaction proceeds, the polar group sulfonic acid group continuously attacks the molecular chain of polyethersulfone, making the molecular chain of polyethersulfone gradually become more polar, and the solvation effect with the solvent becomes larger and larger. , th...

Embodiment 5-12

[0049] According to the method shown in embodiment 1, adopt the different consumption of chlorosulfonic acid to give an example.

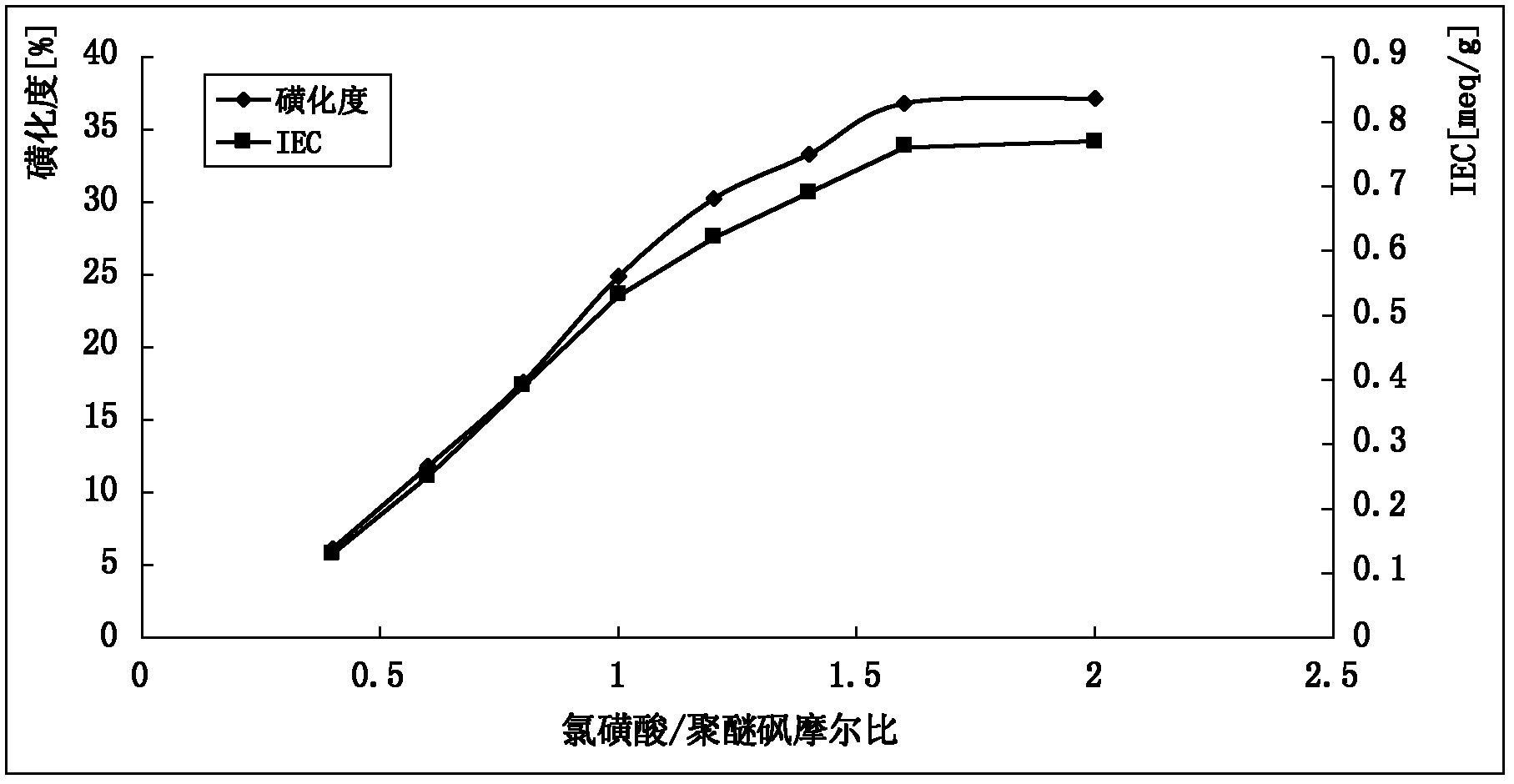

[0050] The amount of chlorosulfonic acid, that is, the molar ratio of chlorosulfonic acid and polyethersulfone is an important parameter affecting the degree of sulfonation of polyethersulfone sulfonation reaction. In this experiment, the sulfonation reaction was studied by adopting different ratios of chlorosulfonic acid / polyethersulfone, and the results are shown in the table below:

[0051] Influence of the amount of chlorosulfonic acid on the sulfonation reaction

[0052]

[0053] The above reaction chlorosulfonic acid addition rate is 3s / d, stirring speed 800r / min. The total reaction time is 360min, the reaction temperature is 10°C, and the solvent is concentrated sulfuric acid.

[0054] From the above table and attached figure 1 It can be seen that with the increasing ratio of chlorosulfonic acid / polyethersulfone, the degree of sulfonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com