Preparation method for gelatin/PHBV (Poly(3-Polyhydroxybutyrate-3-Hydroxyvalerate)) blend film

A technology of blending film and gelatin, applied in the field of preparation of gelatin/PHBV blended film, can solve problems such as poor strength and elasticity, and achieve the effects of good mechanical properties, simple equipment and process, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

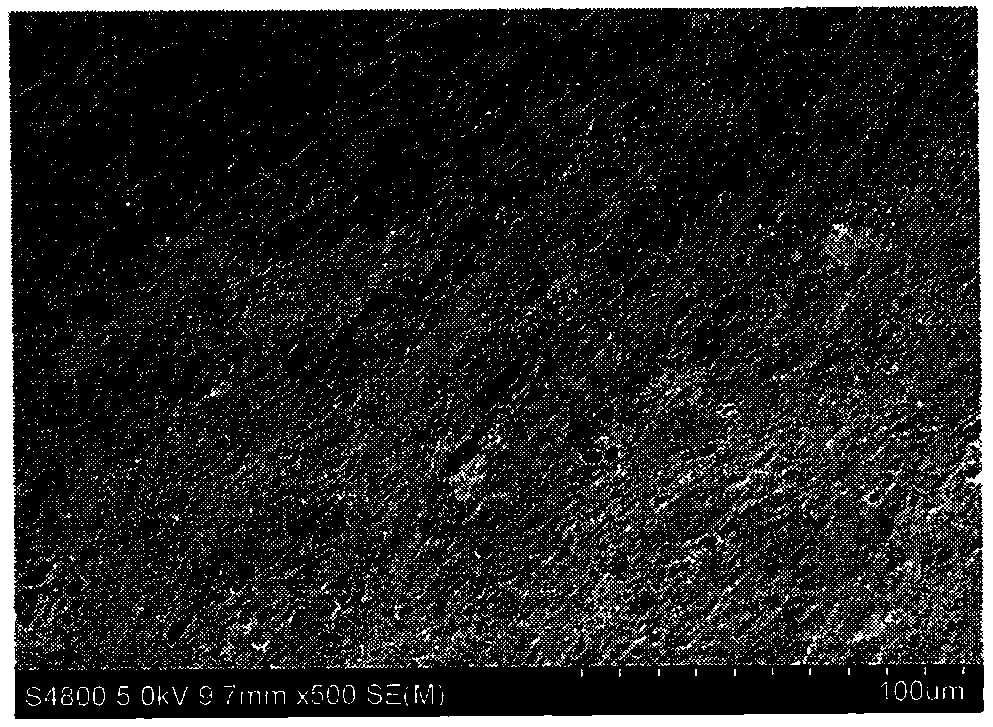

Image

Examples

Embodiment 1

[0014] Add 2 g of gelatin into 50 mL of 2,2,2-trifluoroethanol, stir to dissolve it completely, and prepare a gelatin solution with a concentration (w / v) of 4%. Dissolve 2g of PHBV in 50mL of 2,2,2-trifluoroethanol to make a uniform solution with a concentration (w / v) of 4%, then mix the above-mentioned gelatin solution with the PHBV solution, add 0.02g of glycerol, and magnetically After stirring for 45 minutes, the mixed solution was cast on a polytetrafluoroethylene mold, placed in a fume hood to dry at room temperature for 4 hours, and then vacuum-dried at 30°C until the solvent was completely evaporated to obtain a gelatin / PHBV blend film.

Embodiment 2

[0016] Dissolve 2g of gelatin in 40mL of 40°C dimethyl sulfoxide, stir well to obtain a uniform gelatin solution with a concentration (w / v) of 5%; dissolve 3g of PHBV in 50mL of 40°C dimethyl sulfoxide, fully After stirring, a solution with a concentration (w / v) of 6% was obtained. Mix the above 40mL 5% gelatin solution and 50mL 6% PHBV solution, then add 0.05g of glycerol, stir at 40°C for 2h, cast the solution on a mold made of a hydrophobically treated glass plate, and dry at room temperature After 4 hours, put it into a vacuum drying oven at 30° C. and dry until the solvent is completely evaporated to obtain a gelatin / PHBV blend film.

Embodiment 3

[0018] 4 g of gelatin was weighed and dissolved in 50 mL of 2,2,2-trifluoroethanol, and stirred to completely dissolve to prepare a gelatin solution with a concentration (w / v) of 8%. Dissolve 8g of PHBV in 100mL of 2,2,2-trifluoroethanol, and make a uniform solution with a concentration (w / v) of 8% after completely dissolving, then mix the above gelatin solution and PHBV solution, and add 0.24g of ethylene glycol Alcohol, after stirring for 60 minutes, pour the mixed solution on a hydrophobically treated glass plate, put it in a fume hood and dry it at room temperature for 4 hours, then dry it in vacuum at 30°C until the solvent is completely evaporated, and then the gelatin / PHBV blend film can be obtained .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com