Method for measuring hydrogen sulfide content in desulfurized amine

A technology of desulfurization amine solution and determination method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of reduced absorption efficiency, long analysis time, poor repeatability and accuracy, and achieve reduced production costs, stable chromatographic baseline, The effect of saving purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Instruments and reagents

[0018] 6820 gas chromatograph with TCD detector (Agilent); Porapak S, 3 m × 1 / 8 inch (OD) stainless steel column (Agilent); 5 mL gas-tight syringe with lock valve; 10 μL manual Syringe (Agilent); 100μL syringe, 2mL domestic syringe; 20mL headspace bottle and bottle cap, sealing clamp (Agilent).

[0019] Hydrogen sulfide standard gas: hydrogen sulfide content is 9.57%, nitrogen is the base gas (Foshan Kedi Gas Co., Ltd.); methyldiethanolamine (imported); 30% dilute sulfuric acid solution (volume ratio, self-prepared).

[0020] 2. Chromatographic operating conditions

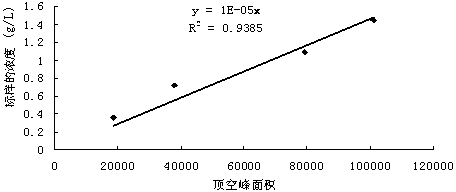

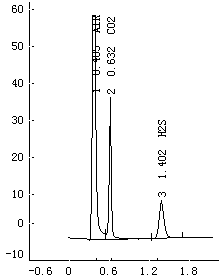

[0021] Through a large number of experiments, the chromatographic operating conditions are determined as follows: the carrier gas is hydrogen; the flow rate of the carrier gas is 15 mL / min, the flow rate of the auxiliary gas is 1 mL / min, and the reference gas is 50 mL / min; The temperature is 180°C; the range is 0, and the injection volume is 50 μL (when the concentra...

Embodiment 2

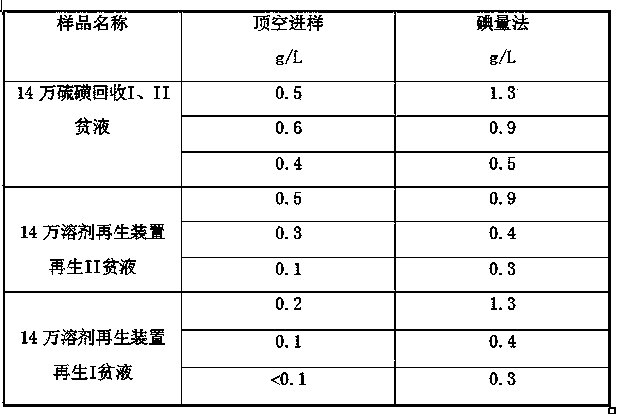

[0040] Use a 2mL pipette to take 2mL of the sample into a 20mL headspace bottle, and seal the bottle cap with a bottle clamp. Take 2mL of 18% (by weight) dilute hydrochloric acid solution with a domestic syringe, inject it into a sealed headspace sampling bottle, shake it repeatedly, let it stand, and cool it to room temperature. Measure the peak area of hydrogen sulfide in the headspace gas phase component of the sample according to the method for measuring the standard solution, and calculate the content of hydrogen sulfide in the sample according to the correction factor of hydrogen sulfide in the standard solution. When using the standard solution to calibrate the instrument and measure the correction factor of hydrogen sulfide in the standard solution, the added dilute acid is 2mL of 18% (weight ratio) dilute hydrochloric acid, and the others are the same as in Example 1.

Embodiment 3

[0042] Use a 2mL pipette to take 2mL of the sample into a 20mL headspace bottle, and seal the bottle cap with a bottle clamp. Use a domestic syringe to take 2mL of 34% (volume ratio) dilute phosphoric acid solution, inject it into a sealed headspace sampling bottle, shake it repeatedly, let it stand, and cool it to room temperature. Measure the peak area of hydrogen sulfide in the sample according to the method for measuring the standard solution, and calculate the content of hydrogen sulfide in the sample according to the correction factor of hydrogen sulfide. When using the standard solution to calibrate the instrument, when measuring the correction factor of hydrogen sulfide in the standard solution, the added dilute acid is 2mL of 34% (volume ratio) dilute phosphoric acid, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com