A method for detecting ethylenediamine in lipoic acid injection

A technology of ethylenediamine and lipoic acid, applied in the field of detection, can solve the problems of easy tailing and peak bifurcation of the chromatographic column, high corrosion of the sampling system, and poor sampling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

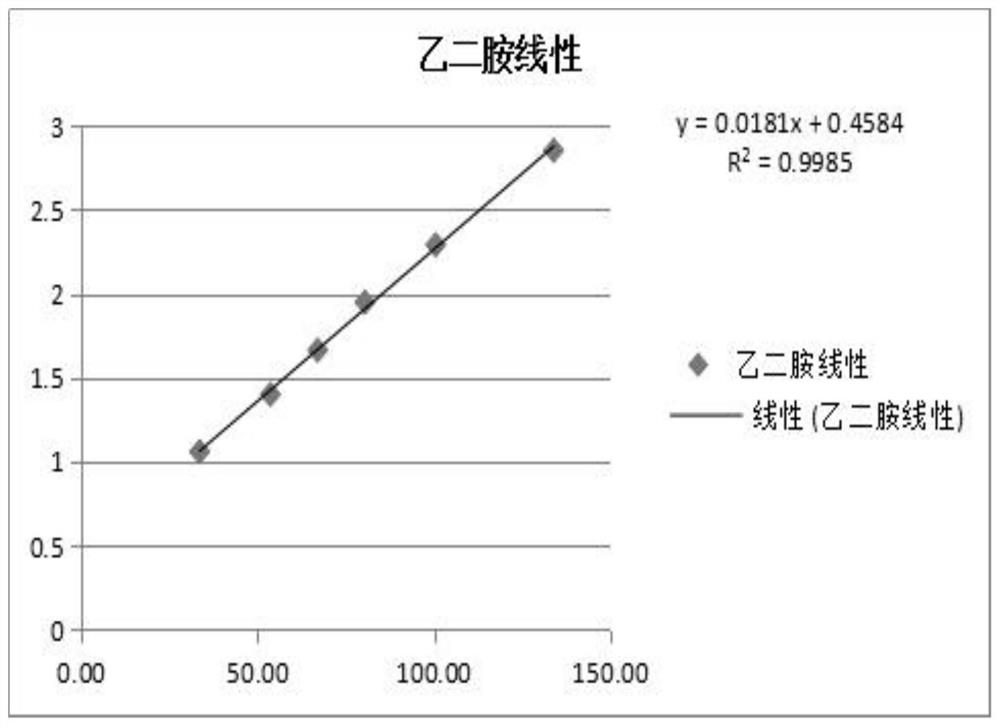

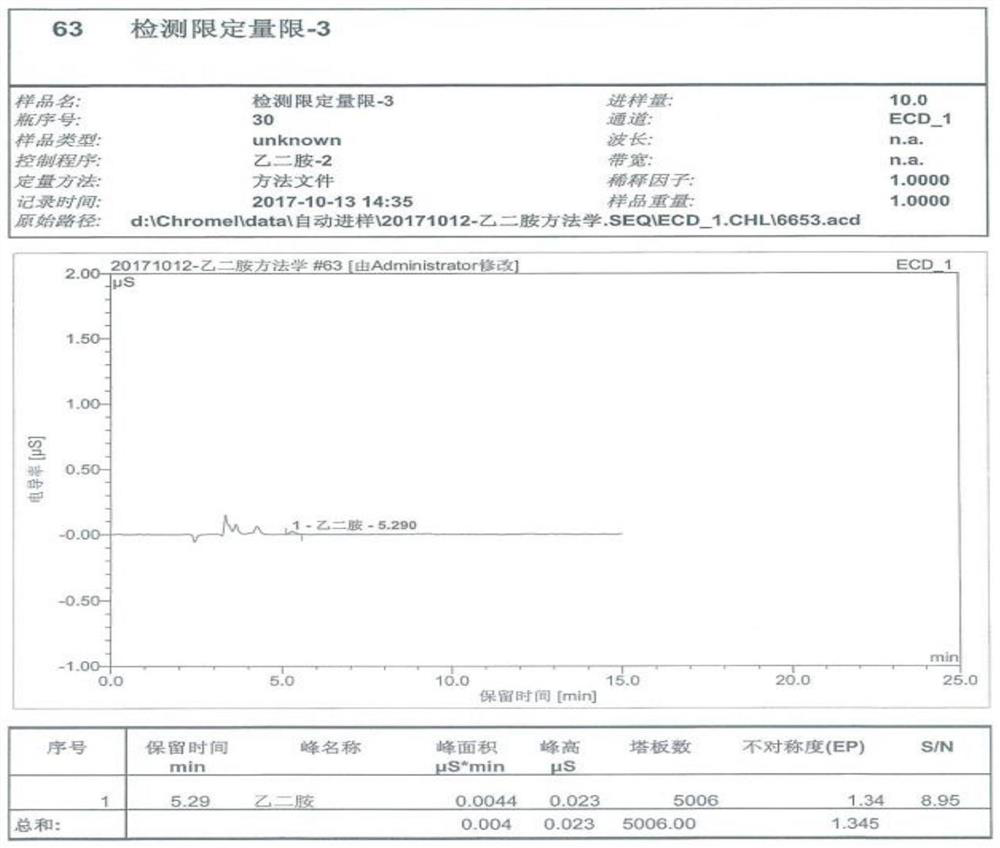

[0053] Detection of ethylenediamine content in lipoic acid injection:

[0054] Chromatographic column: RFIC IonPac CG17, 4mm*50mm, CS17, 4mm*250mm;

[0055] Mobile phase: 15mmol / L methanesulfonic acid is mobile phase A, acetonitrile is mobile phase B, and the volume ratio is 9:1;

[0056] Detector: The detector is a conductivity detector with a suppressor CERS500, 4mm;

[0057] Feed volume: 10 μl;

[0058] Column temperature: 30°C;

[0059] Flow rate: 0.8ml / min;

[0060] Detection steps:

[0061] Accurately measure 1ml of this product, put it in a 100ml measuring bottle, add water to dissolve and dilute to the mark, shake well, and use it as the test solution; take another ethylenediamine reference substance, accurately weigh it, add water to dissolve and quantitatively dilute to 66.7μg / ml solution, as the reference solution. Precisely measure 10 μl each of the test solution and the reference solution, inject them into the ion chromatograph, record the chromatogram, and ...

Embodiment 2

[0068] The applicant fully considered the chemical properties of ethylenediamine, and used a conductivity detector to perform the measurement. Due to the material characteristics of ethylenediamine, there is still obvious tailing on the chromatographic column. Therefore, the asymmetry is used as an index to further screen the mobile phase and injection volume. The screening conditions are shown in Table 2.

[0069] Table 2IC chromatographic condition screening

[0070]

[0071] When the applicant investigates the amount of acetonitrile added, when the volume percentage is greater than 10%, the retention time of ethylenediamine will be less than 5min, which is not conducive to detection, and with the increase of the added amount of acetonitrile, the inhibitory signal is enhanced, so it is determined that methyl sulfonate The volume ratio of acid:acetonitrile is 90:10.

[0072] Research finds that with methanesulfonic acid as mobile phase, as the concentration of methanesulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com