Ultraviolet ozone drying cabinet for cleaning and storing vacuum ultraviolet optical elements

A technology of vacuum ultraviolet light and drying cabinet, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, applications, etc., and can solve the problems that it is difficult to achieve long-term stable storage of vacuum ultraviolet optical components, so as to prevent adverse effects and avoid performance The effect of degradation and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

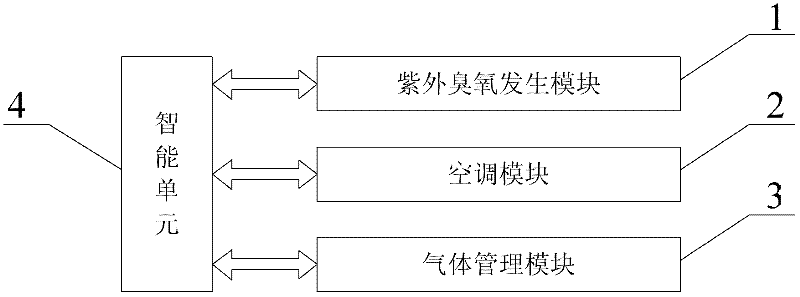

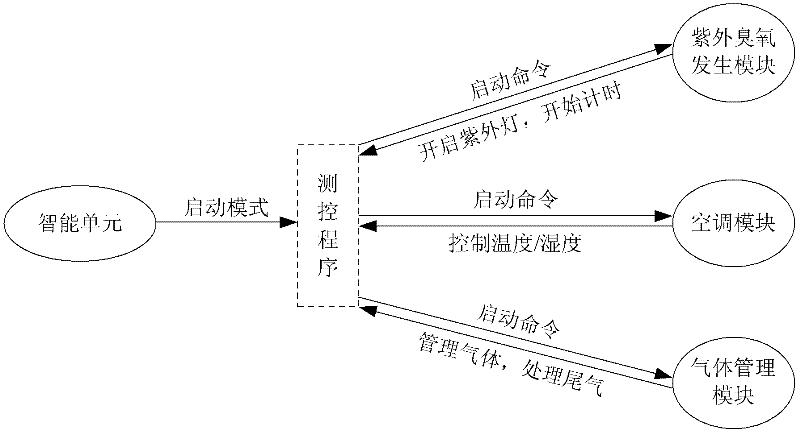

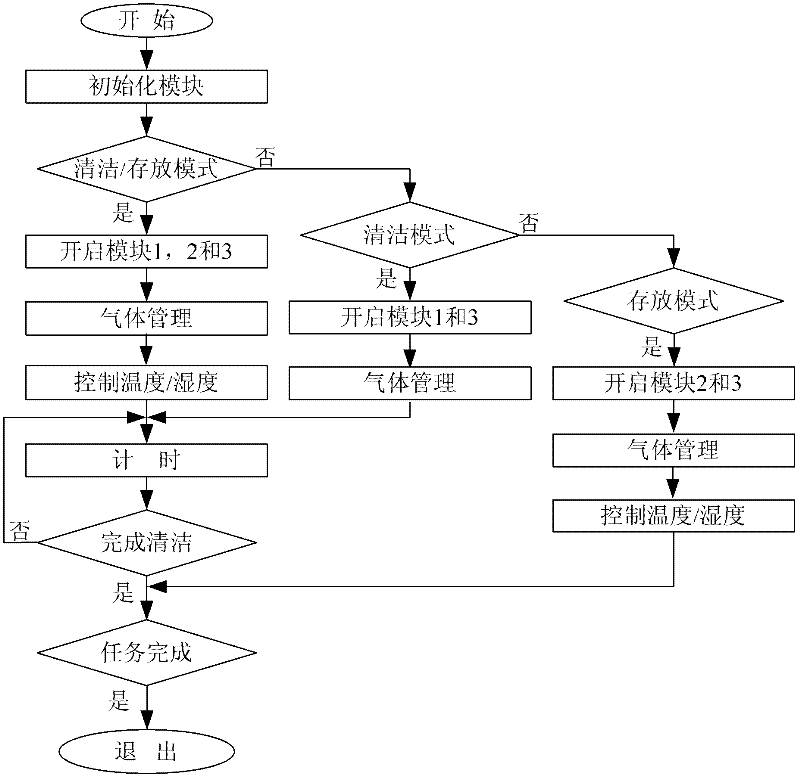

[0028] like figure 1 As shown, the present invention includes an ultraviolet ozone generating module 1, an air conditioning module 2, a gas management module 3 and an intelligent unit 4, wherein: the ultraviolet ozone generating module 1 is mainly composed of an ultraviolet light source; the ultraviolet light source is fused silica or other ultraviolet optical materials (Calcium fluoride, magnesium fluoride, etc.) a mercury lamp, an excimer ultraviolet lamp or a vacuum ultraviolet / deep ultraviolet laser with a radiation wavelength lower than 300nm; the ultraviolet ozone generating module 1 is controlled by an intelligent unit 4 . The air-conditioning module 2 is composed of an air-conditioning machine and a temperature / humidity sensor; the air-conditioning machine has the function of controlling the temperature / humidity in the ultraviolet ozone drying cabinet; the air-conditioning module 2 is controlled by the intelligent unit 4. The gas management module 3 mainly includes gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com