Coal-fired boiler tail gas membrane filtration enriched oxygen recycling method and device

A coal-fired boiler and membrane filtration technology, which is applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of inconvenient use, increased consumption of coal and other fuels, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

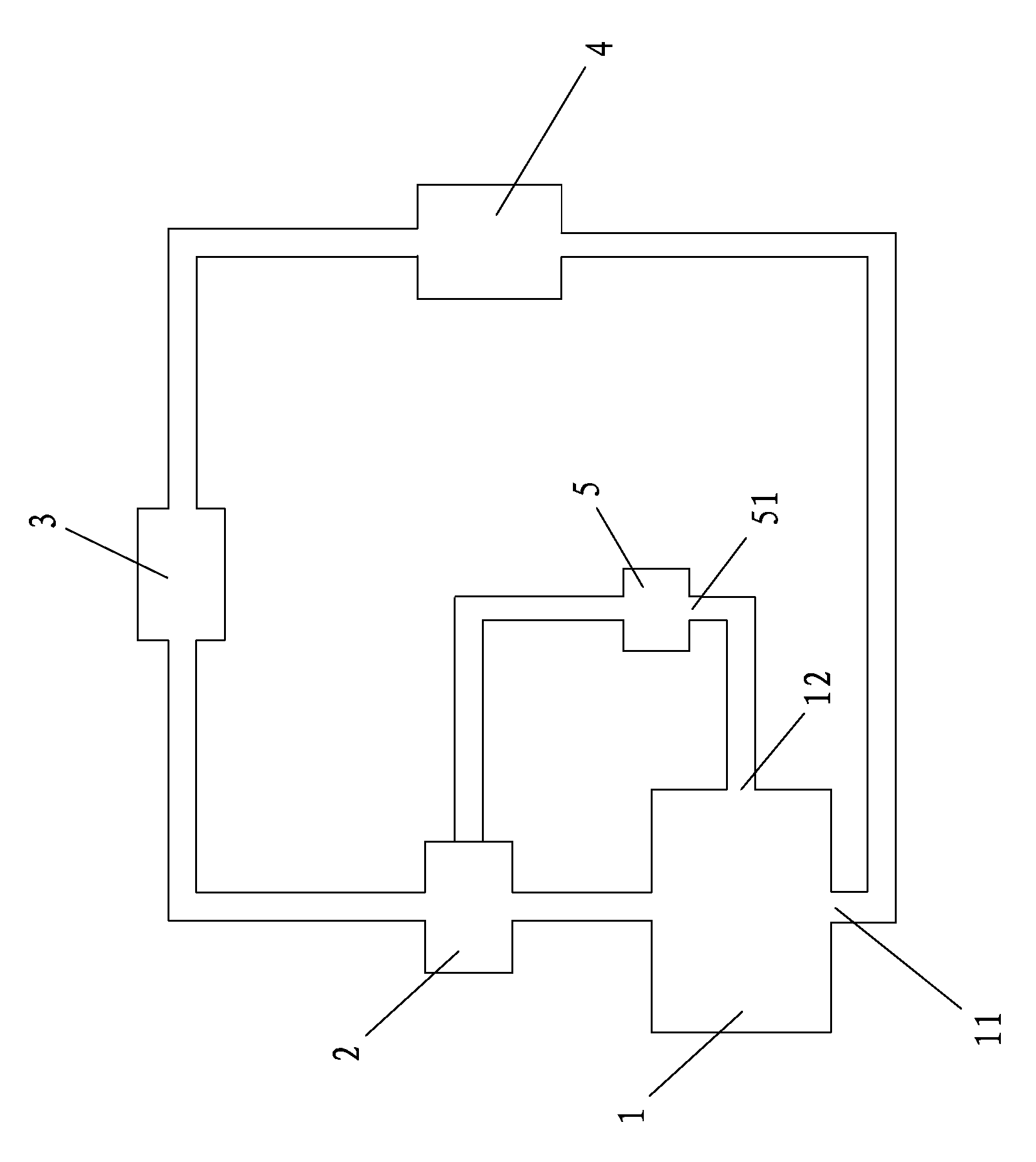

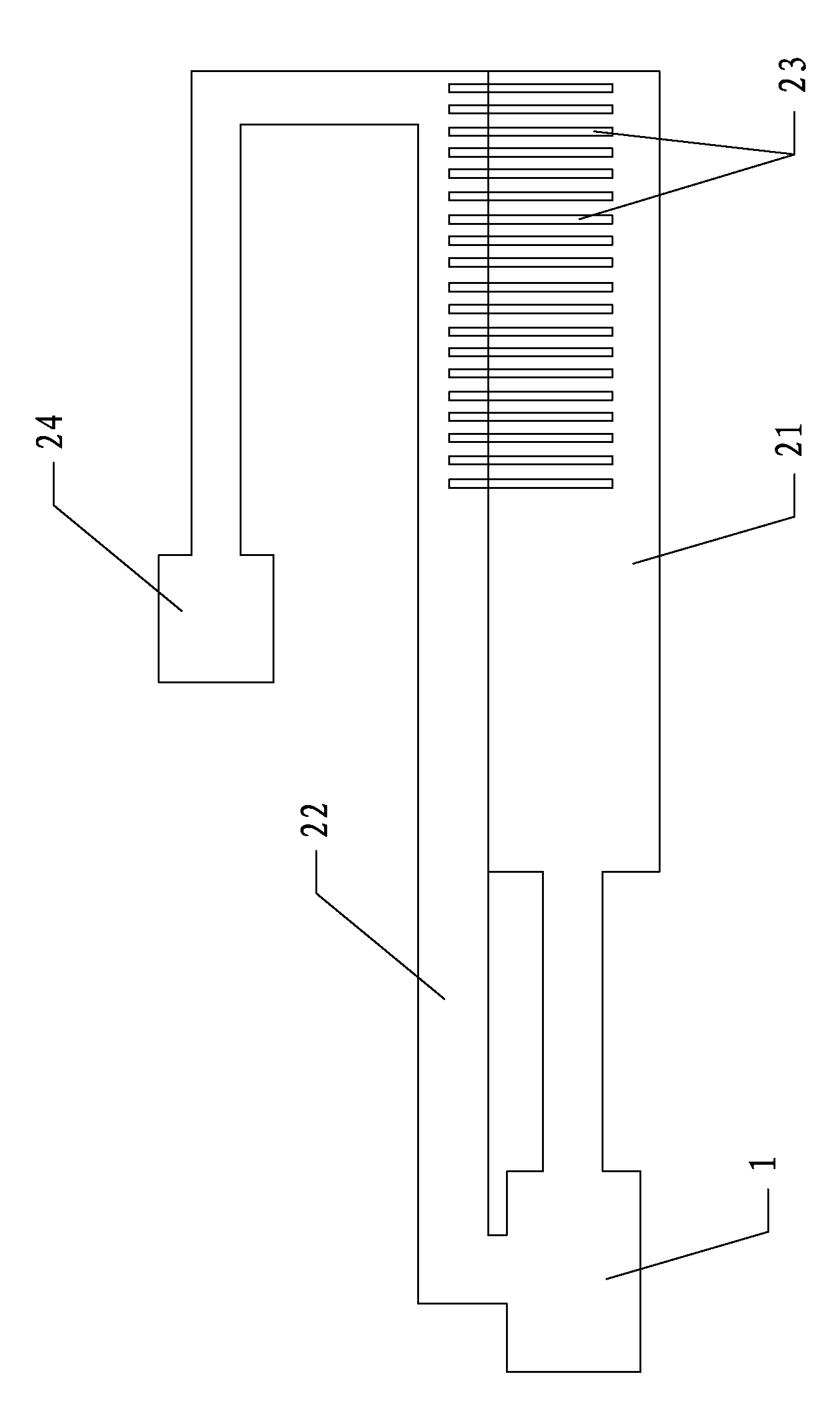

[0057] like figure 1 and figure 2 As shown, the coal-fired boiler tail gas membrane filtration oxygen-enriched recycling method of the present invention comprises the following steps:

[0058] Step A, mix the coal used for boiler 1 combustion with desulfurizer to make desulfurized coal, put the desulfurized coal into the inlet of boiler 1 for combustion; boiler 1 burns the desulfurized coal, which greatly reduces the content of sulfur dioxide gas in the tail gas of boiler 1, and the environment less pollution.

[0059] The desulfurizer of the present embodiment is made by mixing raw materials in the following weight percentages:

[0060] Slaked lime Ca(OH) 2 75%

[0061] Cinder or silica ore produced after coal combustion 15%

[0062] Sodium carbonate Na 2 CO 3 5%

[0063] Amino Acids 5%.

[0064] Step B. Concentrating the tail gas discharged from the coal-fired boiler 1 for waste heat recovery treatment to cool down the tail gas; further, the temperature of the t...

Embodiment 2

[0074] like figure 1 and figure 2 As shown, the coal-fired boiler tail gas membrane filtration oxygen-enriched recycling method of the present invention comprises the following steps:

[0075] Step A, mix the coal used for boiler 1 combustion with desulfurizer to make desulfurized coal, put the desulfurized coal into the inlet of boiler 1 for combustion; boiler 1 burns the desulfurized coal, which greatly reduces the content of sulfur dioxide gas in the tail gas of boiler 1, and the environment less pollution.

[0076] The desulfurizer of the present embodiment is made by mixing raw materials in the following weight percentages:

[0077] Slaked lime Ca(OH) 2 80%

[0078] Cinder or silica ore produced after coal combustion 10%

[0079] Sodium carbonate Na 2 CO 3 5%

[0080] Amino Acids 5%.

[0081] Step B. Concentrating the tail gas discharged from the coal-fired boiler 1 for waste heat recovery treatment to cool down the tail gas; further, the temperature of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com