Integrated flue gas desulfurizing and denitrating purification system and purification technology for same

A flue gas purification system, desulfurization and denitrification technology, applied in air quality improvement, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of energy consumption reduction, inability to remove nitrogen pollutants at the same time, and achieve economic cost reduction , remarkable energy saving effect, technological process and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

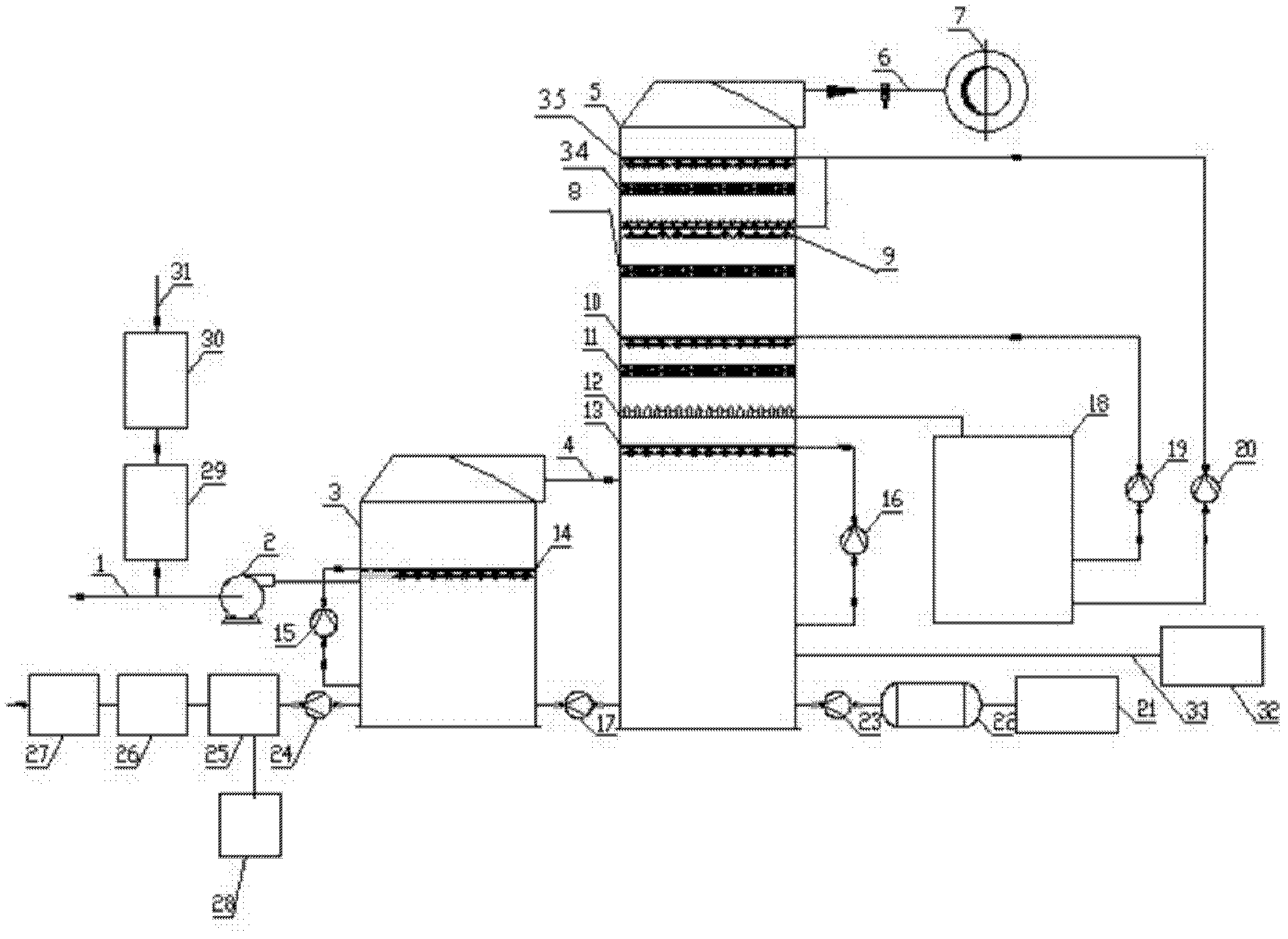

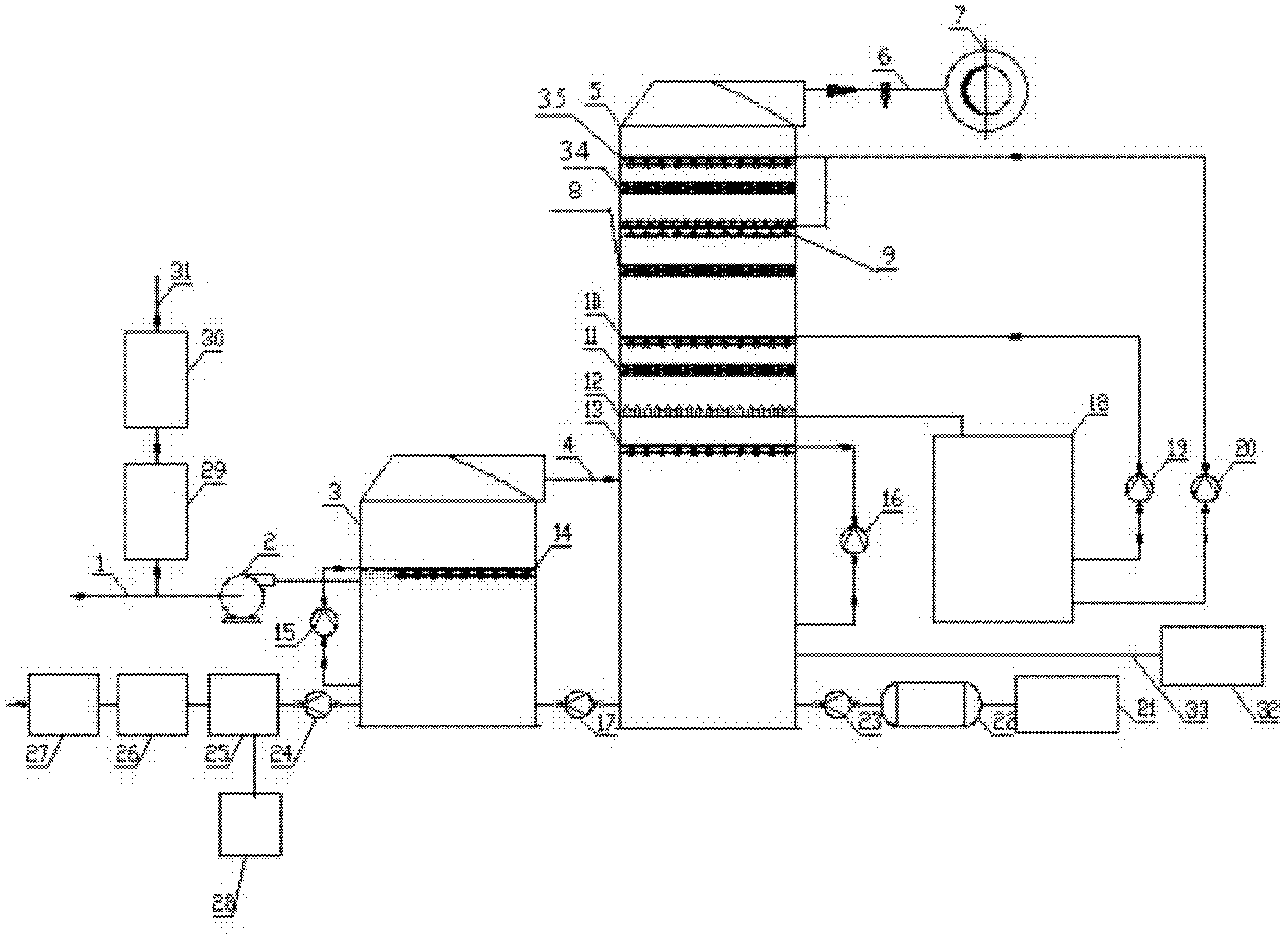

[0056] Such as figure 1 As shown, the present invention is an integrated flue gas purification system for desulfurization and denitrification, including an interconnected flue gas input system, a flue gas absorption and purification system, a clean flue gas discharge system, and a flue gas oxidation system connected to the flue gas input system. system, a concentration system connected to the flue gas input system, a slurry treatment system connected to the concentration system, a slurry oxidation system connected to the flue gas absorption and purification system, and an absorbent delivery system; wherein:

[0057] The flue gas input system includes an input flue 1 and a flue gas input fan 2 connected to each other.

[0058] The flue gas oxidation system is an ozone oxidation system, including an air input pipeline 31 , an air separation device 30 and an ozone generator 29 connected to each other, and the ozone generator 29 is connected to the input flue 1 .

[0059] The con...

Embodiment 2

[0084] Such as figure 1 As shown, the setting and distribution of a flue gas purification system integrated with desulfurization and denitrification are the same as in Embodiment 1.

[0085] The desulfurization and denitrification integrated flue gas purification process carried out by applying the desulfurization and denitrification integrated flue gas purification system of the present invention is the same as that in Example 1, except for the following steps:

[0086] The flue gas entering the concentration tower 3 in step (2) is cooled to 70°C and enters the flue gas purification and absorption system through the transition flue 4;

[0087] In the above embodiment, the absorbent is a potassium hydroxide solution with a mass percentage of 25%; the molar ratio of the ozone to the NO in the flue gas is 1:1; the density of the absorbed saturated slurry reaches 1.3g / cm 3 When entering the saturated slurry discharge pump 17; the density of the concentrated slurry reaches 1.7g...

Embodiment 3

[0090] Such as figure 1 As shown, the setting and distribution of a flue gas purification system integrated with desulfurization and denitrification are the same as in Embodiment 1.

[0091] The desulfurization and denitrification integrated flue gas purification process carried out by applying the desulfurization and denitrification integrated flue gas purification system of the present invention is the same as that in Example 1, except for the following steps:

[0092] The flue gas entering the concentration tower 3 in step (2) is cooled to 60°C and enters the flue gas purification and absorption system through the transition flue 4;

[0093] In the above embodiment, the absorbent is a potassium hydroxide solution with a mass percentage of 8%; the molar ratio of the ozone to the NO in the flue gas is 1:2; the density of the absorbed saturated slurry reaches 1.2g / cm 3 When entering the saturated slurry discharge pump 17; the density of the concentrated slurry reaches 1.5g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com