Composite electric furnace phosphorus slag powder and preparation method thereof

A technology for electric furnace phosphate slag and phosphate slag powder is applied in the fields of cement and concrete admixtures and composite electric furnace slag powder, which can solve the problems of insufficient chemical activity, low level of development and utilization, etc. Inferior, the effect of alleviating the shortage of fly ash and making full use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

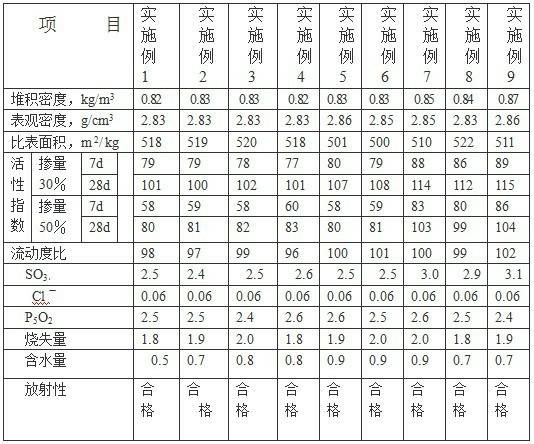

Embodiment 1

[0052] A kind of composite phosphate rock slag powder, is made up of the component of following mass percentage:

[0053] Electric furnace phosphate slag 80%

[0054] Boiling Furnace Bottom Slag 10%

[0055] Triethanolamine 0.05%

[0056] Garden Ming Powder 3.5%

[0057] Modified Phosphogypsum 2.9%.

[0058] The preparation method is as follows: use a Ф2.8×13m barrel mill to dry the phosphate slag from an electric furnace until the water content is 6% by mass percentage, then add other components of the corresponding weight, and grind together to a particle size of 520m 2 / kg can be.

Embodiment 2

[0060] A kind of composite phosphate rock slag powder, is made up of the component of following mass percentage:

[0061] Electric furnace phosphate slag 85%

[0062] Boiling Furnace Bottom Slag 8.0%

[0063] Triethanolamine 0.05%

[0064] Garden Ming Powder 5.0%

[0065] Modified Phosphogypsum 1.95%.

[0066] The preparation method is as follows: use a Ф1.2×13m barrel mill to dry the phosphate slag from an electric furnace until the water content is 3% by mass percentage, then add other components of the corresponding weight, and grind together to a particle size of 500m 2 / kg can be.

Embodiment 3

[0068] A kind of composite phosphate rock slag powder, is made up of the component of following mass percentage:

[0069] Electric furnace phosphate slag 90%

[0070] Bottom slag 5.0%

[0071] Triethanolamine 0.75%

[0072] Garden Ming Powder 3.25%

[0073] Modified Phosphogypsum 1.0%.

[0074] The preparation method is as follows: use a Ф3.2×13m barrel mill to dry the phosphate slag from an electric furnace until the water content is 4.5% by mass percentage, then add other components of the corresponding weight, and grind together to a particle size of 550m 2 / kg can be.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com