Hydrophobe type high-strength wear-resistant plate and manufacturing method thereof

A wear-resistant plate and high-strength technology, which is applied in the field of hydrophobic high-strength wear-resistant plate and its preparation, can solve the problems of powder blockage, lack of hydrophobicity, high impact strength, etc., and achieve alleviating blockage, The effect of high impact strength and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

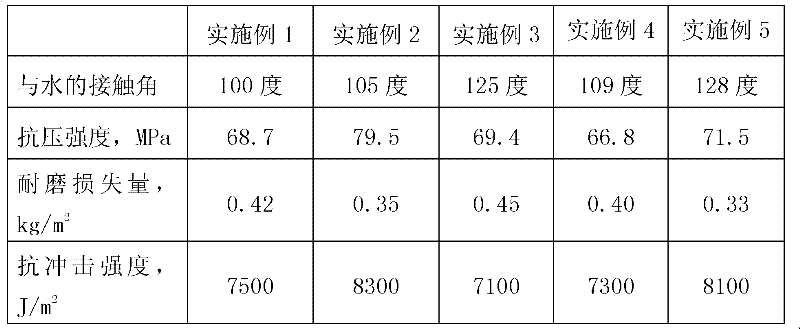

Examples

Embodiment 1

[0031] A hydrophobic high-strength wear-resistant plate, prepared from the following components: 100 kg of ordinary portland cement, 20 kg of silica fume, 20 kg of paraffin emulsion water repellent, 3 kg of naphthalene-based superplasticizer, and 300 kg of quartz sand , 40 kg of ordinary steel fiber, 10 kg of organic fiber, and 40 kg of water.

[0032] The preparation method of the above-mentioned hydrophobic high-strength wear-resistant plate includes the following steps: first weigh the above-mentioned components; stir each component except water evenly, then add water and continue to stir until uniform, pour into a mold for vibration molding, At the same time, holes are reserved on the board. After forming, put it in a room at about 20°C for 1 day, then remove the mold, and then transfer it to hot water at 60°C for 3 days. The required wear-resistant plate can be obtained.

Embodiment 2

[0034] A hydrophobic high-strength wear-resistant plate, prepared from the following components: 80 kg of ordinary Portland cement, 10 kg of silica fume, 40 kg of fly ash, 10 kg of organosilane water-repellent, and 2 polycarboxylate superplasticizers kg, 200 kg of river sand, 30 kg of I-shaped special-shaped steel fiber, and 30 kg of water.

[0035] The preparation method of the above-mentioned hydrophobic high-strength wear-resistant plate includes the following steps: firstly weigh the above-mentioned components; stir each component except water evenly, then add water and continue to stir until uniform, then pour it into a mold to form, and at the same time Connectors are provided on the forming surface of the sheet. After forming, put it in a room at about 20°C for 1 day, then remove the mold, and then transfer it to steam for 3 days.

Embodiment 3

[0037] A hydrophobic high-strength wear-resistant plate, prepared from the following components: 70 kg of ordinary Portland cement, 20 kg of silica fume, 10 kg of slag powder, 3 kg of fluorine-silicon hydrophobic materials, and 3 kg of naphthalene-based superplasticizers kg, 150 kg of corundum, 20 kg of steel fiber, 2 kg of organic fiber, and 35 kg of water.

[0038] The preparation method of the above-mentioned hydrophobic high-strength wear-resistant plate includes the following steps: firstly weigh the above-mentioned components; stir each component except water evenly, then add water and continue stirring until uniform, then pour into a mold for molding. After forming, put it in a room at about 20°C for 1 day, then remove the mold, and then transfer it to 80°C hot water for 3 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com