Fermented cake fertilizer, preparation method and application thereof

A technology for fermented cakes and fermented strains, applied in the field of fertilizer processing, can solve the problems of increasing the irritation and miscellaneous gas of tobacco leaves, affecting the field maturity of tobacco leaves, and being unfavorable for industrial application of cigarettes, and achieves improved appearance quality, good development and application prospects, Non-toxic without any side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

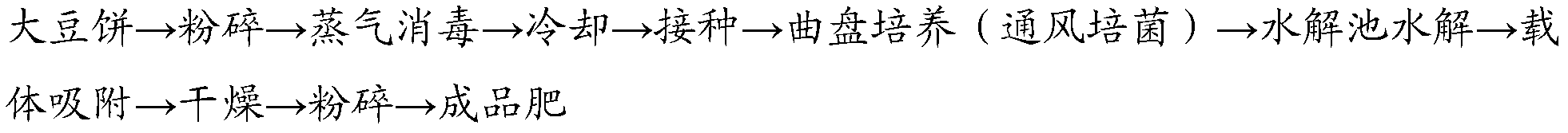

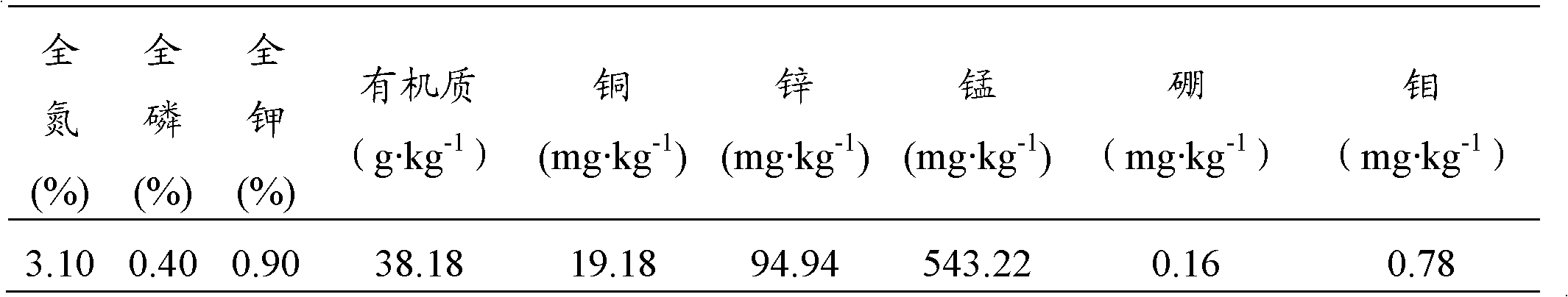

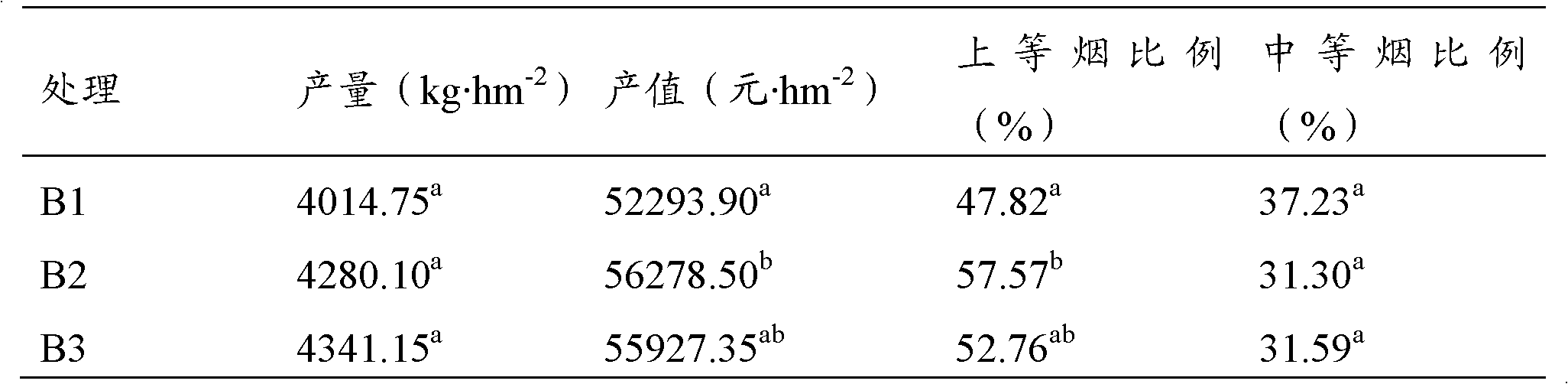

[0030] A kind of fermented cake fertilizer of the present invention is prepared according to the following method, and the method flow chart is as follows figure 1 Shown:

[0031] 1. Sterilization of raw materials: crush the soybean cake mechanically to a fineness of 2mm, then sterilize with steam, cool at 95°C for 30 minutes; sterilize the wheat bran, the method is the same as above.

[0032] 2. Inoculation: when the sterilized wheat bran is cooled to 35° C., mix Aspergillus niger and wheat bran evenly in a weight ratio of 2:1000. The amount of wheat bran is 3% of the bean cake weight. Then the wheat bran inoculated with bacteria is mixed evenly with the sterilized bean cake.

[0033] 3. Fermentation: Put the inoculated bean cakes in a stainless steel tray with a thickness of 5-7cm, and then cultivate them in a culture room with a temperature of 25°C for 40 hours at a temperature of 35°C.

[0034] 4. Hydrolysis: After the bean cakes in the bacteria plate are full, put the ...

Embodiment 2

[0039] A kind of fermented cake fertilizer of the present invention is prepared according to the following method:

[0040]1. Sterilization of raw materials: crush the bean cake mechanically to a fineness of 1mm, then sterilize with steam, cool at 95°C for 30 minutes; sterilize the wheat bran, the method is the same as above.

[0041] 2. Inoculation: when the sterilized wheat bran is cooled to 30° C., mix Aspergillus niger and wheat bran evenly in a weight ratio of 1:1000. The amount of wheat bran is 2% of the bean cake weight. Then the wheat bran inoculated with bacteria is mixed evenly with the sterilized bean cake.

[0042] 3. Fermentation: Put the inoculated bean cake in a stainless steel fungus tray with a thickness of 5-7cm, and then culture it in a culture room with a temperature of 20°C for 36 hours. The plate temperature is 20°C.

[0043] 4. Hydrolysis: After the bean cakes in the bacteria plate are full, put the bean cakes in the plate in the hydrolysis tank, then...

Embodiment 3

[0046] A kind of fermented cake fertilizer of the present invention is prepared according to the following method:

[0047] 1. Sterilization of raw materials: crush the bean cake mechanically to a fineness of 3mm, then sterilize with steam, cool at 95°C for 30 minutes; sterilize the wheat bran, the method is the same as above.

[0048] 2. Inoculation: when the sterilized wheat bran is cooled to 40° C., mix Aspergillus niger and wheat bran evenly in a weight ratio of 5:1000. The amount of wheat bran is 5% of the bean cake weight. Then the wheat bran inoculated with bacteria is mixed evenly with the sterilized bean cake.

[0049] 3. Fermentation: Put the inoculated bean cakes in a stainless steel tray with a thickness of 5-7cm, and then culture them in a culture room with a temperature of 25°C for 48 hours. The temperature of the bacterial tray is 30°C.

[0050] 4. Hydrolysis: After the bean cakes in the bacteria plate are full, put the bean cakes in the plate in the hydrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com