Fertilizer special for continuous cropping flue-cured tobacco, and preparation method and application thereof

A special fertilizer and flue-cured tobacco technology, which is applied in the field of fertilizer production and processing, can solve the problems of affecting the maturity of tobacco leaves in the field, enhancing the stimulation of the cigarette industry, and reducing the quality of tobacco leaves, so as to solve the contradiction between nitrogen application and nitrogen demand, and avoid the greening of flue-cured tobacco Effect of Late Ripening and Improving Tobacco Leaf Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

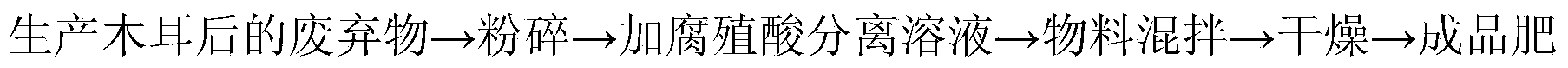

[0050] A special fertilizer for double cropping flue-cured tobacco of the present invention is prepared according to the following method, and the method flow chart is as follows: figure 1 Shown:

[0051] 1. Weighing raw materials: 500kg of waste after producing fungus (medium composition: 78% oak wood chips, 20% bran, 1% gypsum powder and 1% sugar, water content is 65%), 300kg humic acid and 200kg humus.

[0052] 2. Raw material crushing: mechanically crush the waste after producing fungus, with a fineness of 1-2mm.

[0053] 3. Disinfection: Sterilize the pulverized waste with steam, cool at 95°C for 30 minutes.

[0054] 4. Humic acid extraction: Use 0.1M NaOH (sodium hydroxide) solution to extract humic acid according to the mass volume ratio of humic acid raw material: sodium hydroxide solution = 1:10, and then use 1:1 hydrochloric acid to adjust Supernatant to pH=1.

[0055] 5. Treatment of waste after producing fungus: Mix the waste with humic acid supernatant with pH...

Embodiment 2

[0060] A special fertilizer for double cropping flue-cured tobacco of the present invention is prepared according to the following method:

[0061] 1. Weighing raw materials: 800kg waste after producing fungus (medium composition: 73% oak wood chips, 25% bran, 1% gypsum powder and 1% sugar, water content is 65%), 100kg humic acid and 100kg humus.

[0062] 2. Raw material crushing: mechanically crush the crushed waste with a fineness of 1-2mm.

[0063] 3. Disinfection: Sterilize the crushed waste with steam, cool at 95°C for 30 minutes.

[0064] 4. Humic acid extraction: Use 0.1M NaOH (sodium hydroxide) solution to extract humic acid according to the mass volume ratio of humic acid raw material: sodium hydroxide solution = 1:10, and then use 1:1 hydrochloric acid to adjust Supernatant to pH=1.

[0065] 5. Waste treatment after fungus production: Mix the humic acid supernatant with pH=1 with the waste after fungus production, control the water content at 60%, and let it stand...

Embodiment 3

[0068] A special fertilizer for double cropping flue-cured tobacco of the present invention is prepared according to the following method:

[0069] 1. Weighing raw materials: 600kg of waste after producing fungus (medium composition: 80% oak wood chips, 19% bran, 0.5% gypsum powder and 0.5% white sugar, water content is 65%), 200kg humic acid and 200kg humus.

[0070] 2. Raw material crushing: mechanically crush the waste after producing fungus, with a fineness of 1-2mm.

[0071] 3. Disinfection: Sterilize the crushed waste with steam, cool at 95°C for 30 minutes.

[0072] 4. Extraction of humic acid: Use 0.1M NaOH (sodium hydroxide) solution to extract humic acid according to the mass volume ratio of humic acid raw material: sodium hydroxide solution = 1:10, and then use hydrochloric acid to adjust the supernatant to pH=1.

[0073] 5. Waste treatment after fungus production: mix humic acid supernatant with pH=1 with the waste after fungus production, control the water cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com