60wt% of butachlor missible oil prepared from biodiesel and preparation method thereof

A technology of butachlor emulsifiable concentrate and biodiesel, which is applied in botany equipment and methods, preparation of organic compounds, biofuels, etc., can solve the problems of high methanol and catalyst consumption, increased catalyst consumption, and difficulty in recycling, etc., and achieves convenient Product separation, reduction of alkyd-acid ratio, low aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Add p-toluenesulfonic acid and soluble starch in a beaker according to m (p-toluenesulfonic acid): m (starch) = 1:2, dissolve with distilled water, then heat until the solution is clear and transparent, then cool to room temperature, and evaporate by rotary evaporator into a viscous colloid, placed in a muffle furnace, and carbonized at 200°C for 8h. Grind immediately after taking out, and then pass through a 80-mesh sieve to obtain a carbon-based solid acid catalyst.

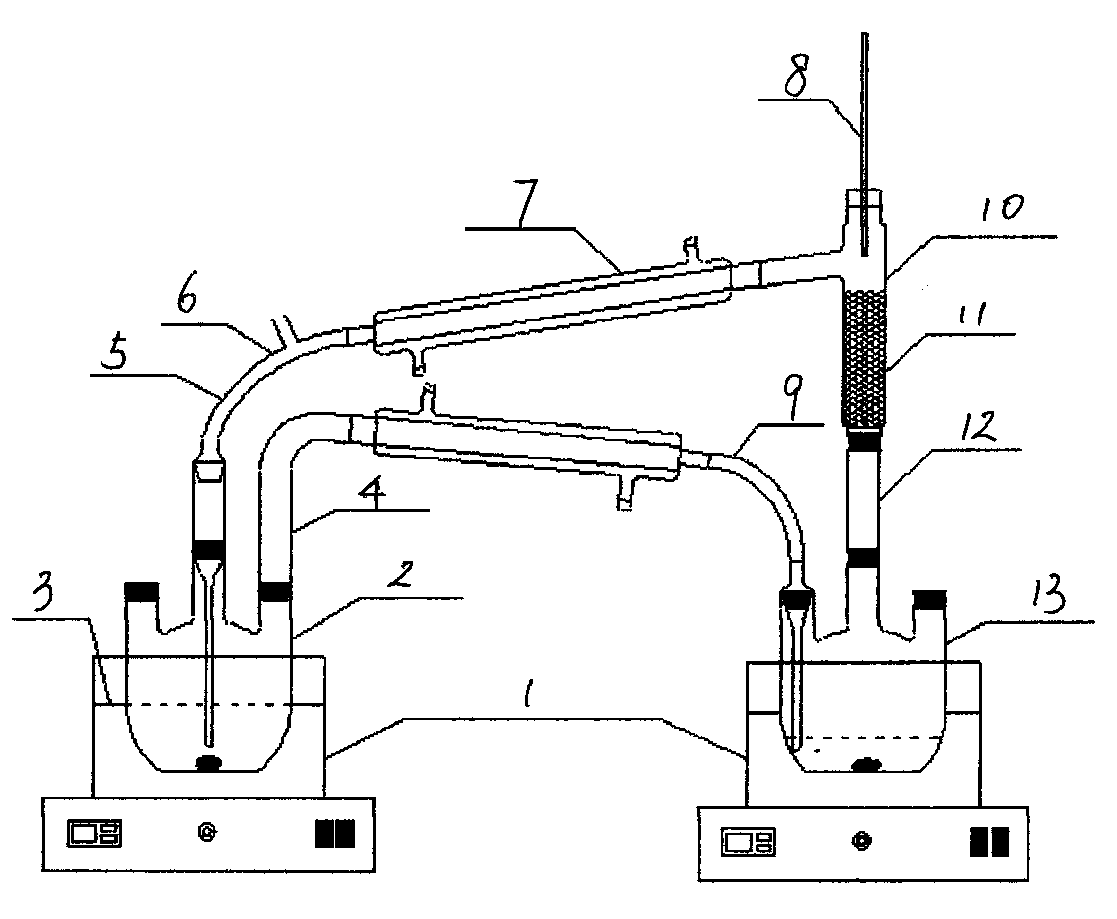

[0021] according to figure 1 After installing the reaction device, a certain amount of oleic acid and a carbon-based solid acid catalyst equivalent to 1.0% oleic acid mass were added to the reactor in sequence, and at the same time, the water bath was turned on for heating, and the temperature of the evaporator water bath was set at 90°C. When the temperature of the reaction water bath reaches 68°C, methanol is added according to the molar ratio of alkyd to 2:1 to start the reaction. Within half an hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com