Surface modification method of nano-grade calcium carbonate used in room-temperature vulcanized silicone adhesive

A nano-calcium carbonate and vulcanized silicone technology is applied in the directions of adhesives, dyed low-molecular-weight organic compounds, fibrous fillers, etc. Stable product quality, enhanced effect, improved hydrophobicity and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

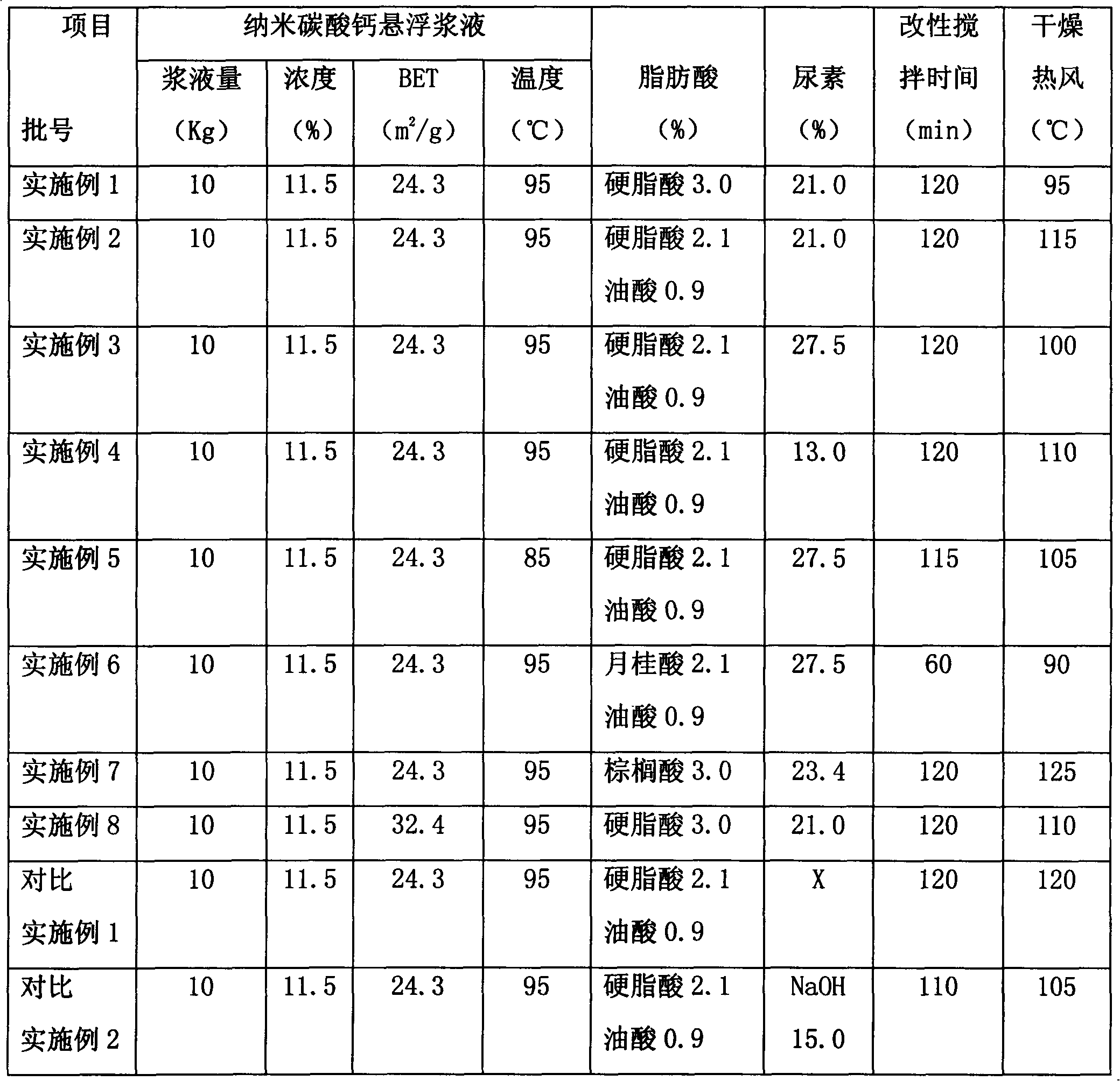

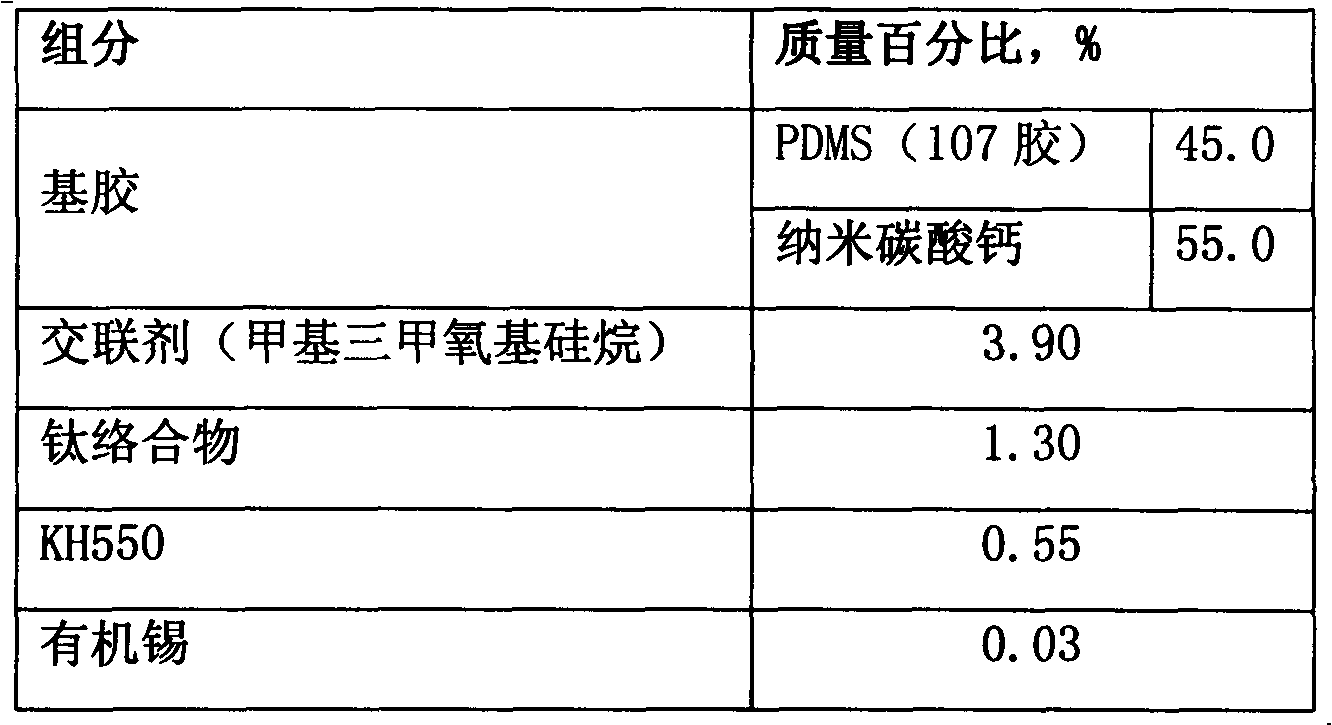

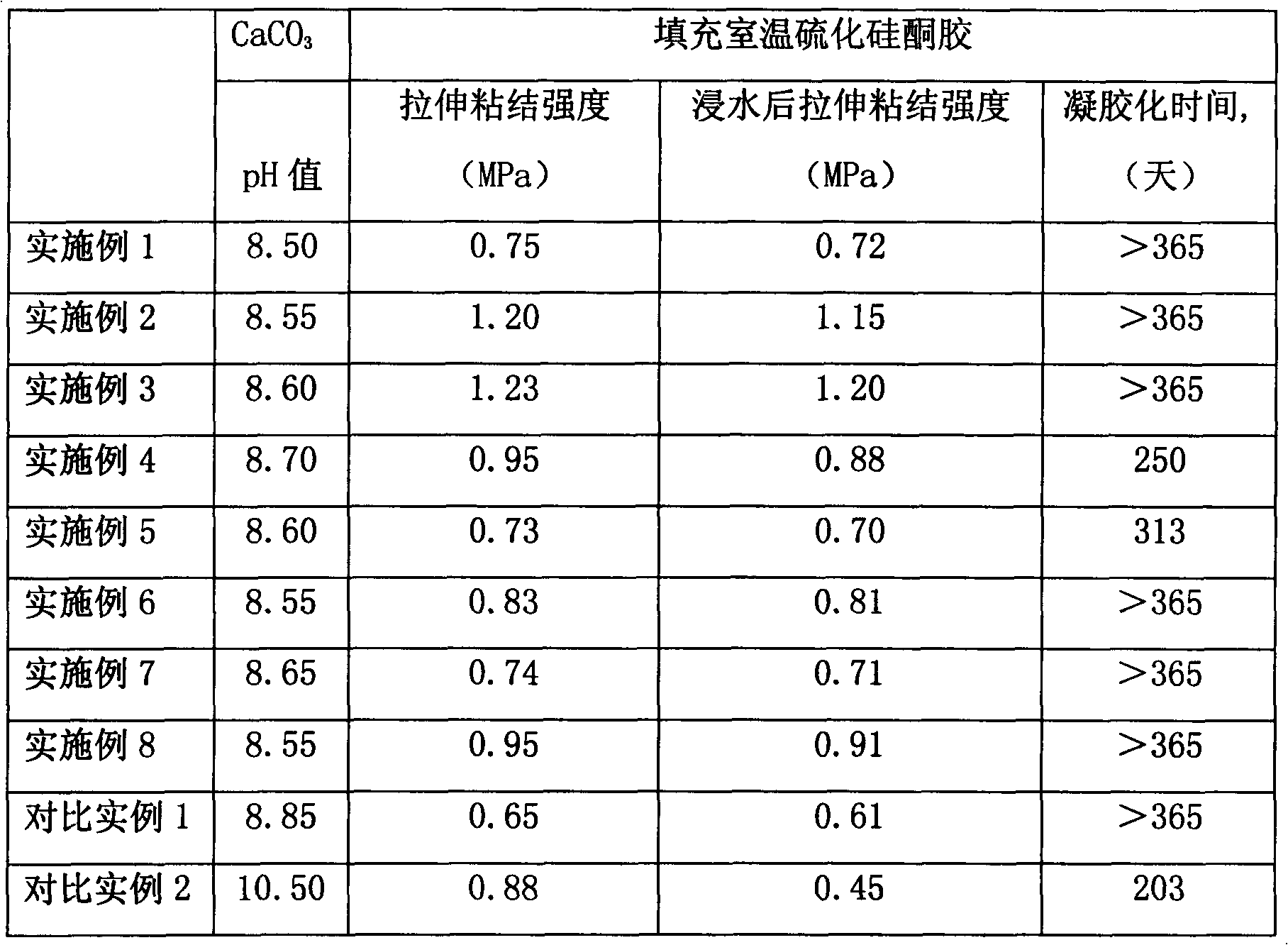

Examples

Embodiment

[0025] 1. Preparation of nano calcium carbonate slurry

[0026] CaCO 3 Limestone with a content greater than 98.5% is calcined at 1050°C for 3 hours to obtain quicklime; quicklime and water are fully digested at a temperature of 90±5°C in a mass ratio of 1:4 to obtain slaked lime slurry; the lime slurry is sieved to remove slag and diluted with water to Ca(OH) 2 Solid content 8.5±0.5%; CO 2 Lime kiln gas with a volume concentration of 30±2% is fed into the lime slurry to react until the pH of the system is 8.5 to prepare nano calcium carbonate slurry. The specific surface area of the dried powder of nano-calcium carbonate slurry is 24.3m 2 / g and 32.4m 2 / g two kinds, the grain size is 80nm and 50nm respectively, showing a cubic regular shape.

[0027] 2. Modification of nano calcium carbonate

[0028] (1) adding the above-mentioned nano-calcium carbonate slurry into a reaction kettle, controlling the temperature at 85-95° C., and stirring to obtain a nano-calcium carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com