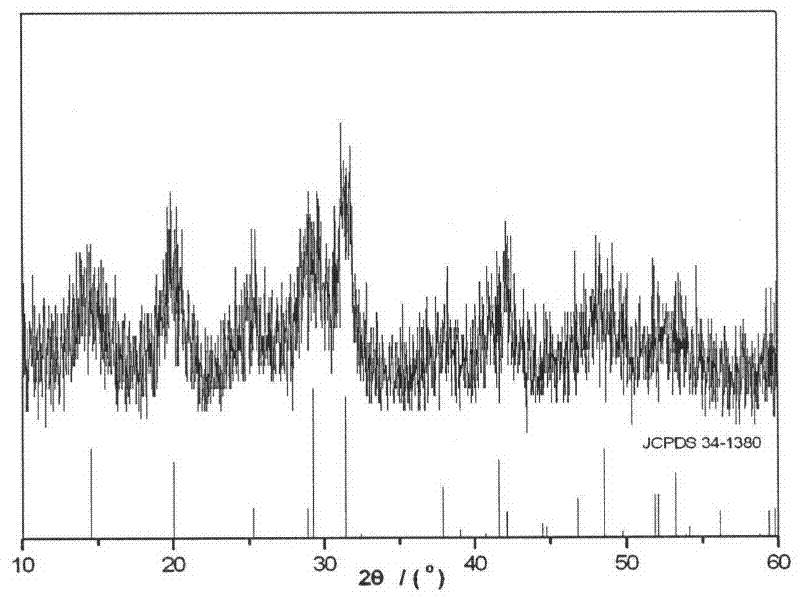

Preparation method of nanowires of lanthanum phosphate activated by cerium and terbium

A technology of lanthanum cerium terbium phosphate and nanowires, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of reducing production costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

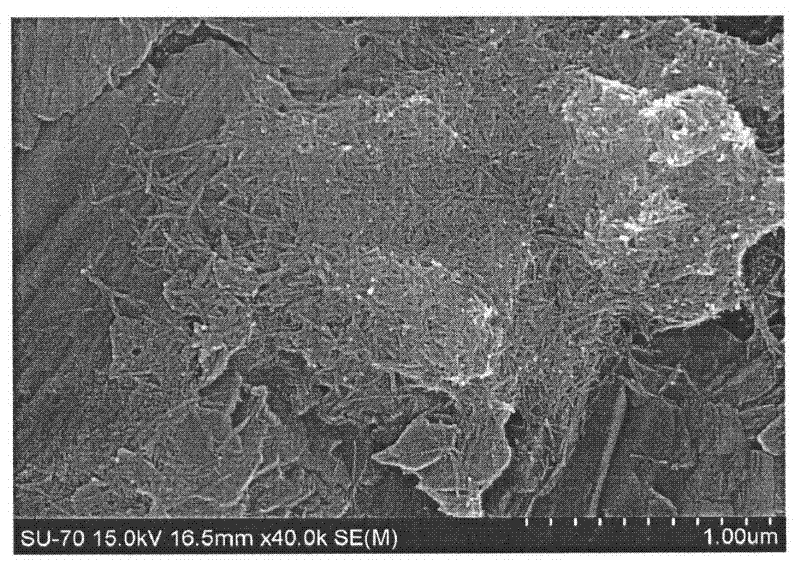

[0062] Embodiment 1 (implementation condition: La 3+ : Ce 3+ :Tb 3+ The molar ratio is 0.68:0.12:0.20, pH=1, 20°C room temperature, aging for 32 hours)

[0063] The specific implementation steps of the preparation method of the lanthanum cerium terbium phosphate nanowires provided by the invention are as follows:

[0064] Step 1: Prepare La separately 3+ 、Ce 3+ , Tb 3+ Saline solution and PO 4 3- saline solution;

[0065] La 3+ 、Ce 3+ , Tb 3+ Saline solution and PO 4 3- The saline solution was prepared with soluble La commonly used in this field. 3+ 、Ce 3+ , Tb 3+ Salt and soluble orthophosphoric acid (PO 4 3- ) salt as the solute and water as the solvent. For example, soluble La 3+ 、Ce 3+ , Tb 3+ The salt can be lanthanum nitrate, cerium nitrate, terbium nitrate, lanthanum chloride, cerium chloride, terbium chloride, etc., the soluble orthophosphoric acid (PO 4 3- ) salts can be sodium phosphate, ammonium phosphate or potassium phosphate, etc., such as ...

Embodiment 2

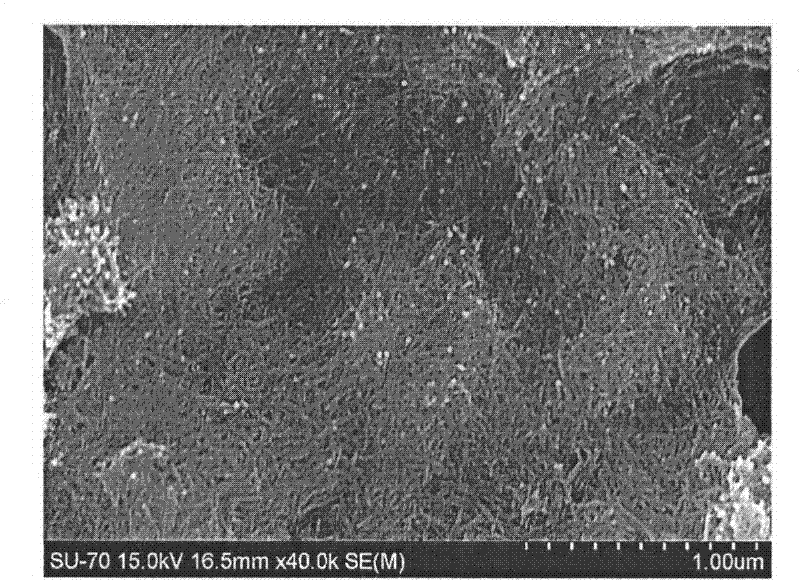

[0078] Embodiment 2 (implementation condition: La 3+ : Ce 3+ :Tb 3+ The molar ratio is 0.6:0.2:0.2, pH=1, aging at room temperature for 48 hours at 23°C)

[0079] Weigh a certain mass of lanthanum nitrate [La(NO 3 ) 3 ·6H 2 O], cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O], terbium nitrate [Tb(NO 3 ) 3 ·6H 2 O] and disodium phosphate [Na 2 HPO 4 2H 2 O], be prepared with deionized water to be lanthanum nitrate, cerium nitrate, terbium nitrate aqueous solution and disodium hydrogen phosphate aqueous solution with the concentration of 0.1 mol / liter respectively, and press La 3+ : Ce 3+ :Tb 3+ The molar ratio is 0.60:0.20:0.20, respectively measure different volumes of lanthanum nitrate, cerium nitrate, and terbium nitrate aqueous solution to prepare La 3+ Ce 3+ Tb 3+ 25 ml of the mixed solution, the La 3+ Ce 3+ Tb 3+ The mixed solution was placed in an Erlenmeyer flask, stirred with a magnetic stirrer at a speed of 180 rpm, and 25 milliliters of the 0.1 mol / liter dis...

Embodiment 3

[0080] Embodiment 3 (implementation condition: La 3+ : Ce 3+ :Tb 3+ The molar ratio is 0.56:0.16:0.28, pH=0.5, aged at 23°C for 24h)

[0081] Weigh a certain mass of lanthanum nitrate [La(NO 3 ) 3 ·6H 2 O], cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O], terbium nitrate [Tb(NO 3 ) 3 ·6H 2 O] and disodium phosphate [Na 2 HPO 4 2H 2 O], be prepared with deionized water to be lanthanum nitrate, cerium nitrate, terbium nitrate aqueous solution and disodium hydrogen phosphate aqueous solution with the concentration of 0.1 mol / liter respectively, and press La 3+ : Ce 3+ :Tb 3+ The molar ratio is 0.56:0.16:0.28, respectively measure different volumes of lanthanum nitrate, cerium nitrate, and terbium nitrate aqueous solution to prepare La 3+ Ce 3+ Tb 3+ 25 ml of mixed solution. the La 3+ Ce 3+ Tb 3+ The mixed solution was placed in an Erlenmeyer flask, stirred with a magnetic stirrer at a speed of 150 rpm, and 25 milliliters of the 0.1 mol / liter disodium hydrogen phosphate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com