Method for preparing biogas by degrading coal with microorganisms

A technology of microbial degradation and biogas, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as coalbed methane depletion, and achieve the effects of low cost, reduced development cost, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

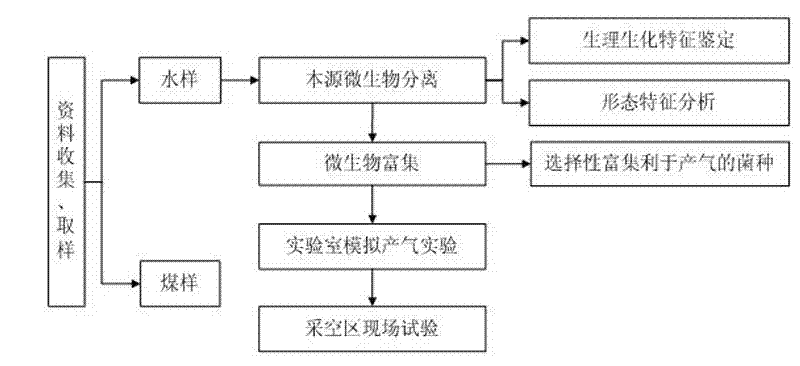

[0034] Embodiment: A kind of method utilizing microbial degradation coal to produce biogas, concrete steps are as follows:

[0035] (1) Collect data, take coal samples and water samples at the same time, and conduct anaerobic bacteria detection on the water samples taken.

[0036] (2) Using the water sample of the mined well as the source of bacteria, in an anaerobic glove box, use the culture medium of methanogens, hydrogen-producing acetogenic bacteria, anaerobic cellulolytic bacteria and sulfate-reducing bacteria to separate and count , to clarify the type of original microorganisms and carry out selective culture. The specific medium formula used is as follows:

[0037] 1) Culture medium for anaerobic hydrogen-producing acetogenic bacteria:

[0038] Glucose 25g, tryptone 3g, beef extract 2.5g, yeast juice 1.5g, NaCl 5g, K 2 HPO 4 1g, MgCl 2 0.4g, FeSO 4 ·7H 2 O 0.3g, L-cysteine 0.5g, pH 7.0-7.2

[0039] 2) Anaerobic cellulolytic bacteria culture medium:

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com