In-pulp hard sizing process for raw paper of food cards

A heavy sizing and crafting technology, applied in textiles and papermaking, paper, papermaking and other directions, can solve the problem that the sizing effect is not in the best state, the combination of film and paper is not fast enough, and it is difficult to use high-speed paper cup machines. and other problems, to achieve the effect of good post-processing lamination effect, good edge water absorption resistance, and less rubber dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

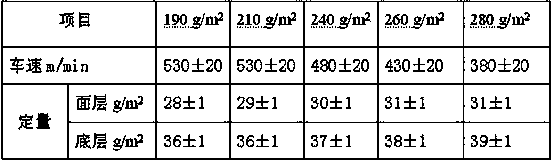

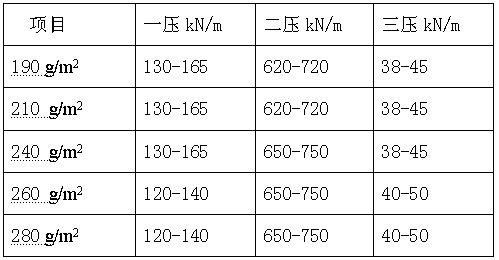

[0022] Example 1 Base paper for paper cups

[0023] 1. Pulping and pulping

[0024] Composition of surface layer pulp: 40% NBKP kraft softwood pulp and 60% LBKP kraft hardwood pulp mixed pulping, refining, to get the top pulp;

[0025] Add 30% sodium hydroxide solution to adjust the pH to 7.0.

[0026] Core slurry composition: 43% Hardwood BCTMP pulp, 30% NBKP kraft softwood pulp, 27% LBKP kraft hardwood pulp is mixed and pulped, refined to obtain core pulp;

[0027] Add 30% sodium hydroxide solution to adjust the pH to 7.0;

[0028] Bottom pulp composition: 53% NBKP kraft softwood pulp, 47% LBKP kraft hardwood pulp mixed pulping, refining, to get bottom pulp

[0029] Add 30% sodium hydroxide solution to adjust the pH value to 7.0, and add 30% sodium hydroxide solution to adjust the pH value to 7.0.

[0030] 2. Re-sizing in pulp

[0031] Add 15kg / ton of aluminum sulfate to the surface layer slurry, core layer slurry, and bottom layer slurry, and stir evenly;

[00...

Embodiment 2

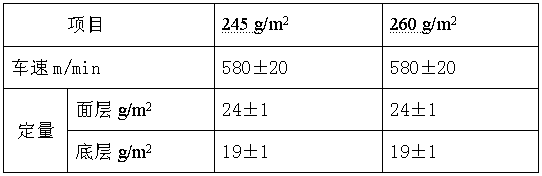

[0045] Embodiment 2 Noodle bowl base paper

[0046] 1. Pulping and pulping

[0047] Composition of surface layer pulp: 40% NBKP kraft softwood pulp, 60% LBKP kraft hardwood pulp mixed pulping, refining, to get the top pulp;

[0048] Add 30% sodium hydroxide solution to adjust the pH value to 8.5;

[0049] Core slurry composition: 75% Hardwood BCTMP pulp, 13% NBKP kraft softwood pulp, 12% LBKP kraft hardwood pulp is mixed and pulped, refined to obtain core pulp;

[0050] Add 30% sodium hydroxide solution to adjust the pH value to 8.5;

[0051] Bottom pulp composition: 51% NBKP kraft softwood pulp, 49% LBKP kraft broadleaf wood pulp mixed pulping, refining, to get bottom pulp;

[0052] Add 30% sodium hydroxide solution to adjust the pH to 8.5.

[0053] 2. Re-sizing in pulp

[0054] Add 20kg / ton of aluminum sulfate to the surface layer slurry, core layer slurry, and bottom layer slurry, and stir evenly.

[0055] Add 25kg / ton of cationic rosin to the surface layer sl...

Embodiment 3

[0067] Example 3 Lunch box base paper

[0068] 1. Pulping and pulping

[0069] Composition of surface layer pulp: 17% NBKP kraft softwood pulp, 83% LBKP kraft hardwood pulp mixed pulping, refining, to get the top pulp;

[0070] Add 30% sodium hydroxide solution to adjust the pH value to 8.0;

[0071] Core slurry composition: 73% Hardwood BCTMP pulp, 5% NBKP kraft softwood pulp, 22% Sulphate hardwood pulp is mixed and pulped and refined to obtain core pulp;

[0072] Add 30% sodium hydroxide solution to adjust the pH value to 8.0;

[0073] Bottom pulp composition: 17% NBKP kraft softwood pulp, 83% LBKP kraft broadleaf wood pulp mixed pulping, refining, to get bottom pulp;

[0074] Add 30% sodium hydroxide solution to adjust the pH to 8.0.

[0075] 2. Re-sizing in pulp

[0076] Add 20kg / ton of aluminum sulfate to the surface layer slurry, core layer slurry, and bottom layer slurry, and stir evenly.

[0077] Add 25kg / ton of cationic rosin to the surface layer slurry an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com