Method for efficiently catalyzing TMB (Tetramethylbenzidine) color development reaction by using carbon nanoparticles

A technology of carbon nanoparticles and color reaction, applied in the field of nanometers, can solve the problems that no one has reported about carbon nanoparticles, and achieve the effects of short color development time, high catalytic efficiency, and cheap materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

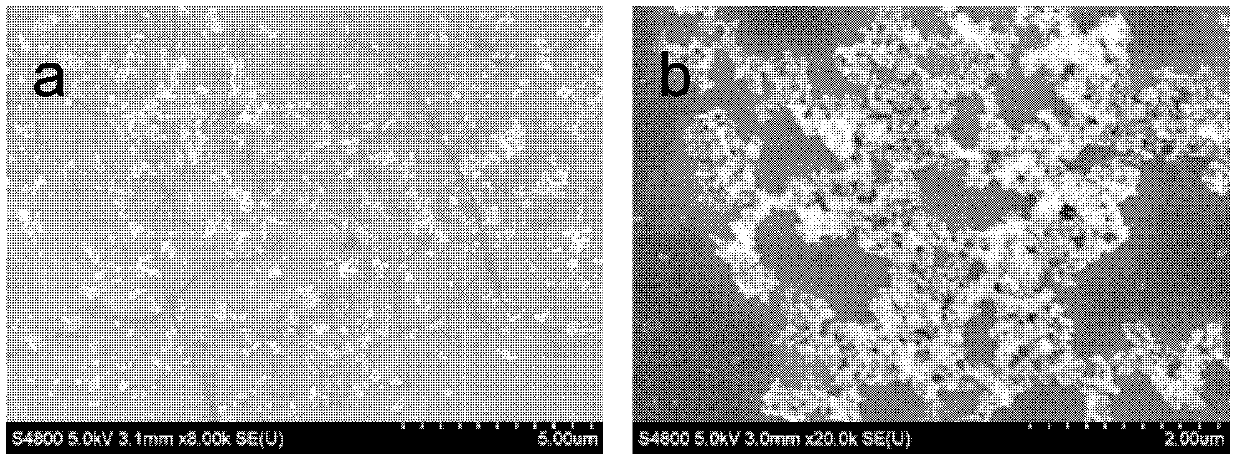

[0033] Weigh 13 mg of non-carboxylated carbon nanoparticles, ultrasonicate them in water for one hour with SDS surfactant, then drop them on silicon wafers, and use SEM to characterize them. Weigh 13 mg of carboxylated carbon nanoparticles, ultrasonically treat them in water for one hour with SDS surfactant, then drop them on silicon wafers, and use SEM to characterize them. Take a certain amount of carbon quantum dots and drop them on a silicon wafer, and use TEM to characterize; figure 1 , the dispersion of carbon nanoparticles is relatively uniform after treatment with surfactant, and the color rendering effect is better.

Embodiment 2

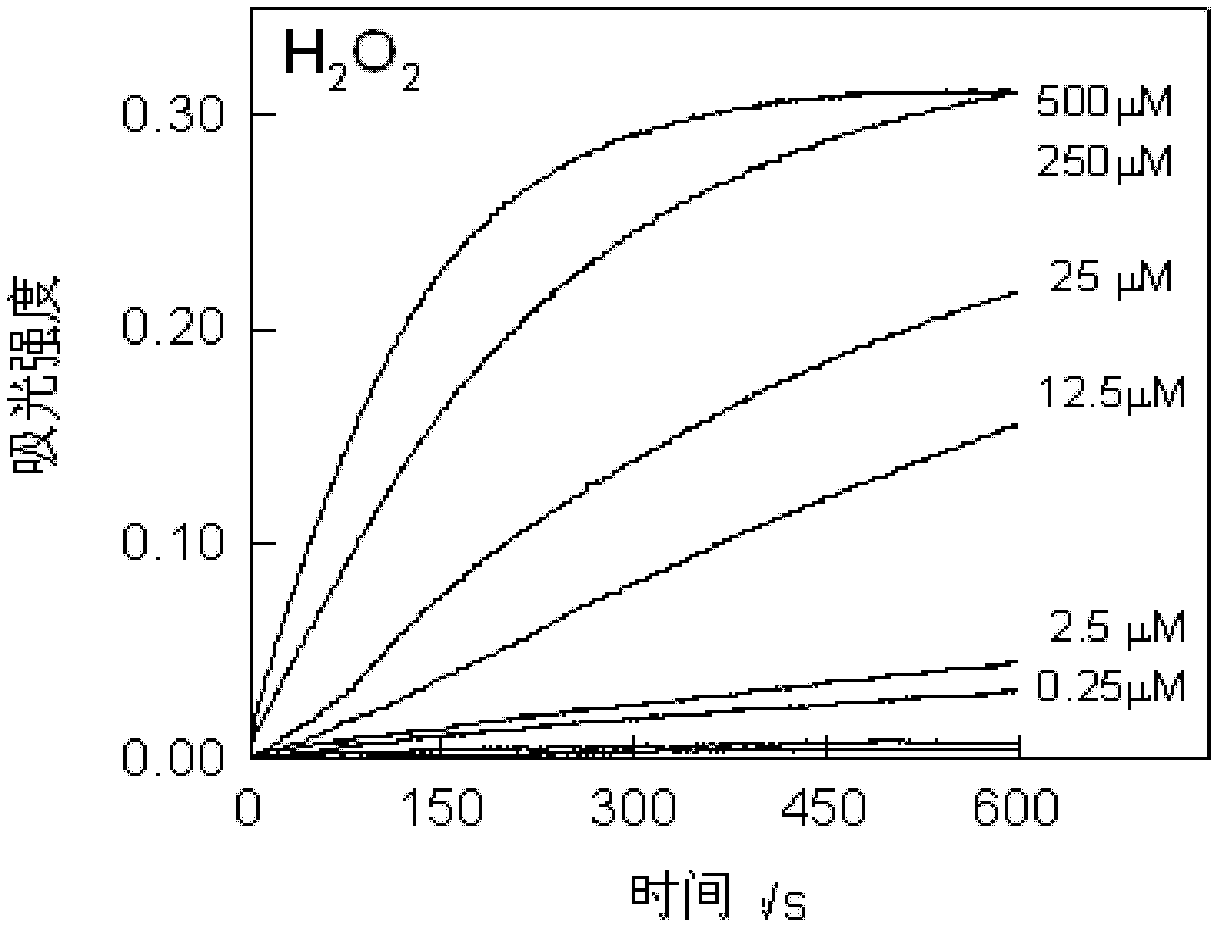

[0035] At room temperature, 250 μM TMB solution (1M concentration) and different concentrations of H 2 o 2 (respectively 0, 0.25, 2.5, 12.5, 25, 250, 500μM) was added to 400μL of water, and then a certain concentration of CNPs-SDS was added, and the absorption value was measured at a wavelength of 652nm as a function of time; figure 2 , when the other amounts remain unchanged, with the increase of hydrogen peroxide concentration, the color development of TMB reaction catalyzed by CNPs-SDS is more obvious, H 2 o2 The preferred addition amount is 500 μM per 400 μL of water.

Embodiment 3

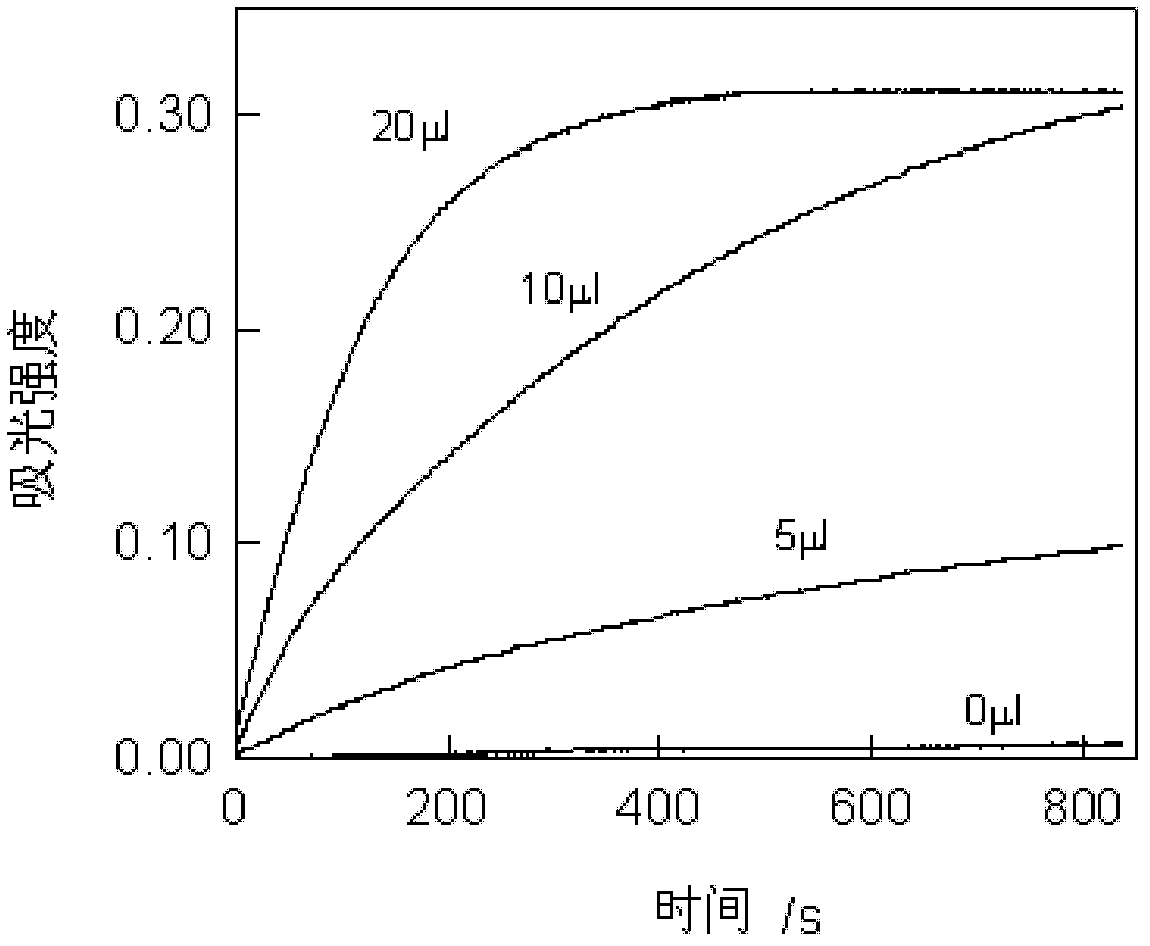

[0037] At room temperature, 250 μM TMB solution (1M concentration) and 250 μM H 2 o 2 Add 400 μL of water, and then add different concentrations of CNPs-SDS (respectively 0, 5, 10, 20 μL), and measure the absorption value over time at a wavelength of 652 nm; image 3 , indicating that in the case of other amounts remaining unchanged, the color of the TMB reaction is significantly catalyzed with the increase of the amount of CNPs-SDS, and the preferred addition amount of CNPs-SDS is 10 μL per 400 μL of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com